-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

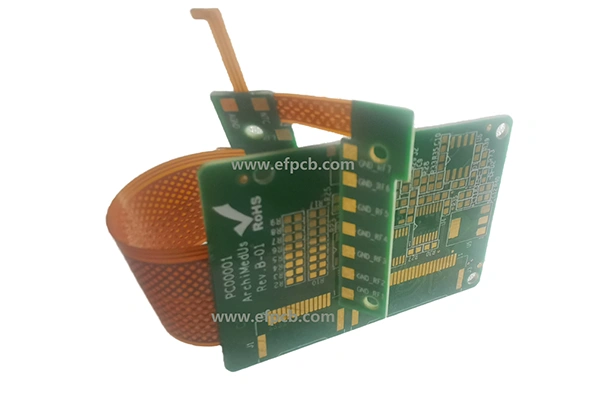

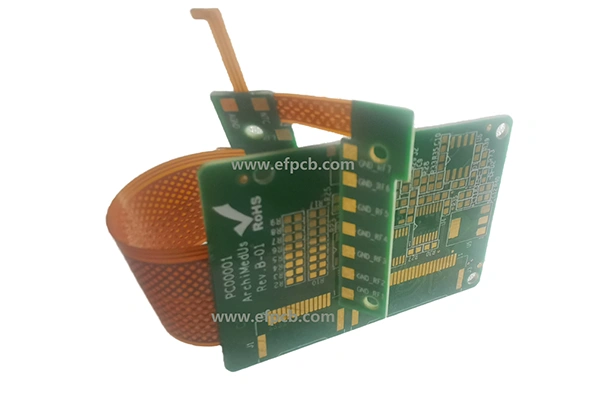

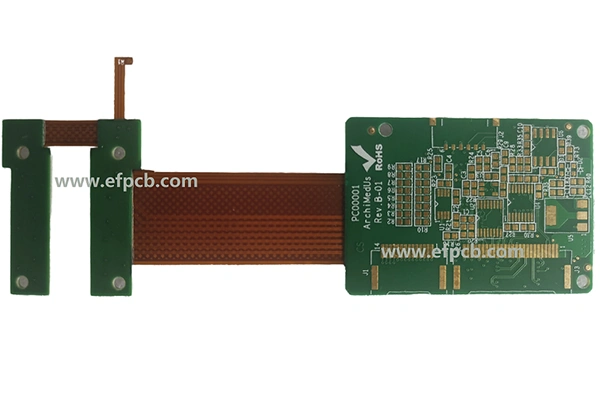

Layer count: 6 layer

Material: FR4, 1.6mm, high TG +2 mil PI, 1 OZ for all layer

Minimum trace: 4 mil

Minimum space(gap): 5 mil

Minimum hole: 0.15mm

Surface finished: ENIG

Panel size: 22*128m

Characteristics: High TG + 2 mil PI, impedance control, IPC Class 3

In the dynamic electronic industry, rigid flexible PCBs have become the determining factor for future electronic devices. With the stiffness of a rigid PCB and the flexibility of a flexible circuit, rigid flexible PCBs offer unparalleled performance and flexibility in many applications. But what is it that makes them the go-to option for so many engineers and designers? Let’s look at what’s driving their popularity.

One the biggest benefit of rigid flexible PCBs is the reduction in the size and weight of the electronic devices. These PCBs which combine rigid and flexible layers in a single board, replace bulky connectors and cables. As a result, they are well-suited for small gadgets such as smartphones, wearables, and medical devices where space is limited.

Enhanced Reliability

Rigid flexible PCBS are reliable. The rigid and flex sections connect seamlessly, which means there are less solder joints, and there is less chance of a solder joint failing and causing a connection failure. They can also be bent or twisted as the flexible sections are robust enough not to break due to these actions, which means that you can use rigid flexible PCBs in environments that demand high reliable, such as automotive or aero applications.

Cost Efficiency

Although the cost of manufacturing of rigid flexible PCBs can be higher when compared with traditional PCBs, the cost of production is far more efficient. Combining several rigid and flexible boards into a single design eliminates risk, and the use of additional connectors, wiring and assembly procedures is no longer necessary. The result is streamlined manufacturing, faster assembly and reduced long-term maintenance cost.

Versatility in Applications

Rigid flexible PCBs are used in many industries ranging from consumer electronics to the nuclear industry. Because of their versatility to be shaped into small spaces or complex shapes, they are vital for futuristic technologies such as IoT devices, robotics, 5G infrastructure and more.

To sum up, rigid flex PCBs provides the most balanced solution between flexibility, reliability and performance. With increasing demand for smaller, more intelligent and power efficient devices, these PCBs are fast becoming the preferred solution for engineers across the globe.