-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

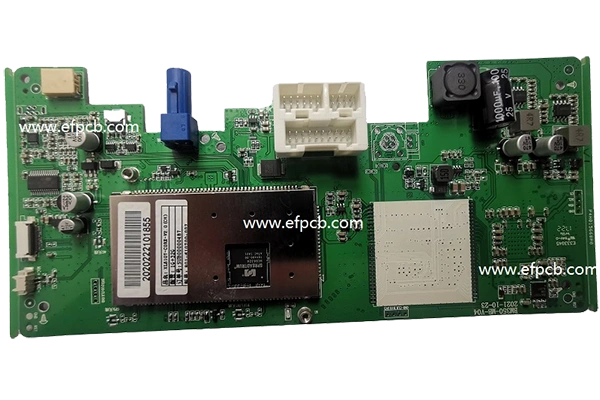

Part No.: E0615060179C

Layer count: 6 layer

Material: FR4, 1.6mm, 1 OZ for all layer

Minimum trace: 5 mil

Minimum space(gap): 5 mil

Minimum hole: 0.20mm

Surface finished: LF HASL

Panel size: 198*68mm/1up

Characteristics: multilayer, min packing 0201, model assembly, lead free assembly, ROHS compliant

A rapid growth in automobile industry is driving the demand for high end multimedia system. Automotive multimedia is shaping the future of driving – from touchscreens and navigation systems to in-car entertainment and voice assistants. PCB assembly is at the core of these developments, a critical process that determines the performance and reliability of the complex system solutions.

The automotive multimedia system's PCBs require assembly that is sufficiently rugged to perform adequately well in both high-volume production and long-term use. They face harsh environments for heat cycling, shock, vibration, EMI EMC and more. Specializing in the manufacture and assembly of rugged and precision products for the automotive industry in particular builds a focus in automotive.

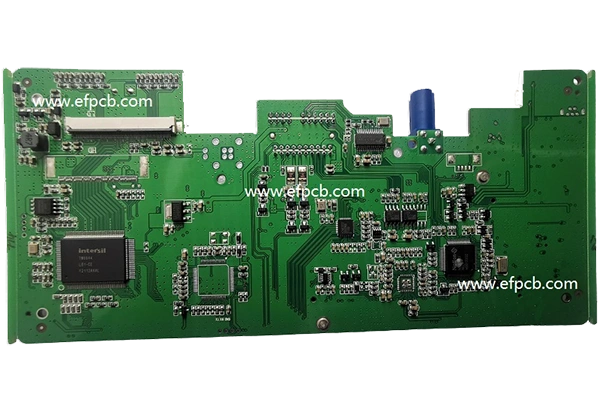

One of the key aspects of automotive multimedia PCB assembly is High Density Interconnect (HDI) technology. This paves way for miniaturization and allows a multiple chips like processor, memory chip and communication modules to be placed in one board. The end result is a smaller, more power efficient system that fits within the size limitations of today's vehicles without sacrificing functionality.

Thermal management is also an important element in manufacturing PCBs for automotive multimedia. Multimedia systems components dissipate a great deal of heat especially in high end applications such as streaming, GPS navigation, and real time connectivity. To achieve reliable operation in a harsh environment, advanced thermal designs are introduced including thermal vias, heat sinks, special material, and etc.

Top companies in automotive multimedia PCB assembly services industry are evidently focused on providing car automobile manufacturer with customized services. These standards include features such as high speed operation, low power consumption, and compatibility with advanced infotainment technologies such as 5G connectivity and AI-based voice recognition.

Besides that, producers also apply strict test to guarantee the reliable products. Functional testing, thermal cycling, EMI testing among others to validate the assembled PCBs meet the stringent automotive industry requirement.

As per the report by Allied Market Research, the global automotive electronics market is anticipated to register a significant CAGR of 7.9% from 2023 to 2030. This is because of the increasing use of multimedia systems in cars, demonstrating the need for high quality PCB assembly services in the automotive industry. In summary, PCB assembly for automotive multimedia is a foundation element in designing the modern vehicle, one which allows for seamless integration of technologies that elevate the driving experience. Applying innovative designs, advanced materials, stringent quality control, the companies are providing world-class, reliable and state of art solutions which meet the versatile and burgeoning demands of automobile industry.