-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

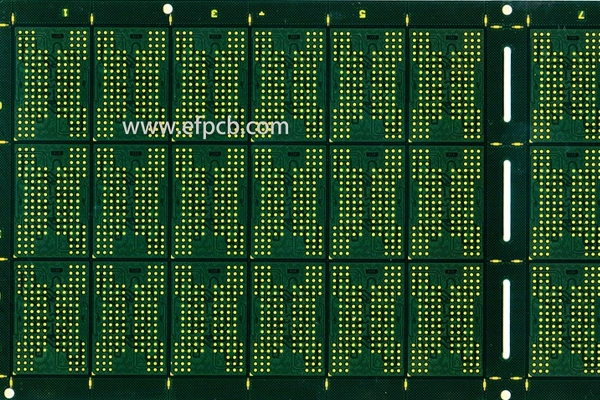

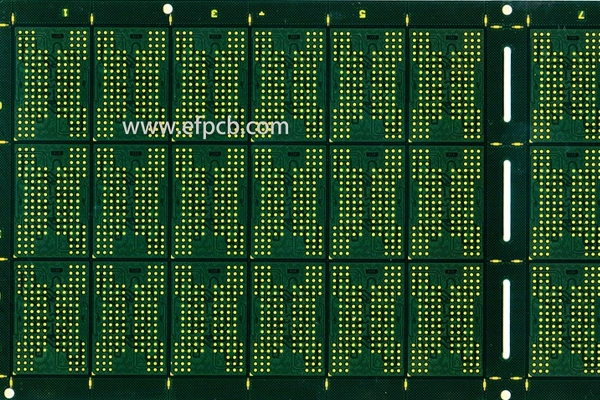

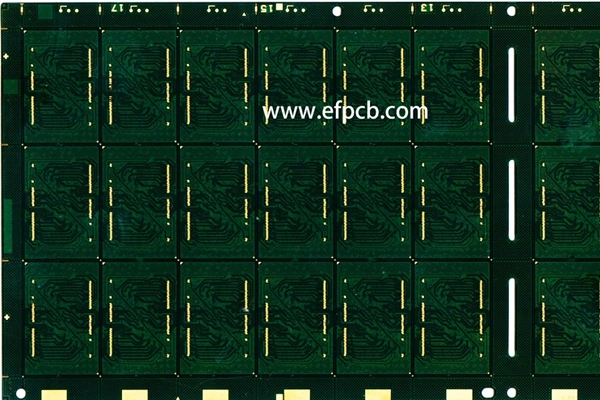

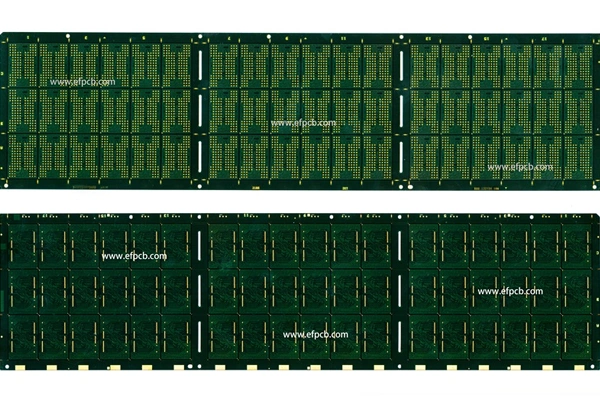

Part No. : E0636060119C

Substrate thickness : 0.30+/-0.03mm

Layer count : 6 layer

Core Material : HL832NXA

Solder Mask : AUS308

Minimum trace : 30 um

Minimum space(gap): 25 um

Minimum hole: 0.075 mm

Surface finished: ENEPIG

Unit size: 28*15mm

The production process of IC substrate is very complex, generally it includes the following steps:

One of the popular applications of DDR4 Board is wide and encompasses aspects such as personal computing, and then covers enterprise level servers. The following is a detailed summary of the application areas of DDR4 Board:

1. Personal computer

DDR4 is essential to personal computers. Meanwhile, memory bandwidth and capacity demand is rising as processor performance becomes faster and faster. DDR4 memory is the one that has gained popularity as the primary upgrade to the memory in personal computers, thanks to high speed of transmission and large memory capacity. DDR4 memory is perfect for gamers, graphic designers and daily office users who need the stability and performance.

2. Workstation

DDR4 memory is also of importance in the field of workstations. Typically workstations must handle large amounts of complex data and graphics with extremely high performance requirements on memory. The information bandwidth and capacity of DDR4 memory matches or is higher than that of traditional memory, and the memory supports multichannel technology for improved data transmission efficiency. This allows for better work efficiency as well as more efficient working.

3. Server and Data Center

Besides being used in the field of servers and data centers, DDR4 memory is also being applied in the fields. With big responsibilities of dealing with extremely high request volume and large amounts of data in servers, and data centers, there are high requirements in terms of memory performance, reliability and stability. DDR4 memory has replaced DRAM for its low power consumption, high reliability, large capacity, and, of course, price. Additionally, a feature present on DDR4 memory is also the ECC (Error Correction Code) functionality, which enables getting rid of the data errors in memory and therefore raise the data integrity of memory.

4. Embedded system

DDR4 memory has been beginning to appear in the embedded systems field. Low power consumption, high performance, and stability are typically necessary requirements for embedded systems. Because DDR4 memory has the advantage of low power consumption, high speed transmission, and reliability, it has become an ideal memory for embedded system board. The application of DDR4 memory is more spread out in the embedded systems which process large amounts of data with corresponding real time requirements.

5. Other fields

DDR4 memory is also applied to some special fields such as high performance computing (HPC), cloud computing and the Internet of Things (IoT), in addition to the above fields. These fields require very good memory performance, capacity, and power consumption and DDR4 memory can support the development of related fields.

In short, DDR4 Board is widely used owing to its large capacity, high speed transmission, low power consumption as well as high reliability. The DDR4 memory will remain to develop with increasing demands for applications and continuous development of technology.