Various Aspects of the Quick Turn PCB

Keywords: Quick Turn PCB, Quick Turn PCB Manufacturer

Empowering makers to satisfy demands or complete activities faster than any time in recent memory, Quick turn PCB is a sort of PCB. For clients, meeting the most squeezing plans and requesting cutoff times has made it much more straightforward.

Speedy Turn PCB Benefits

A few benefits are presented by picking this administrations like:

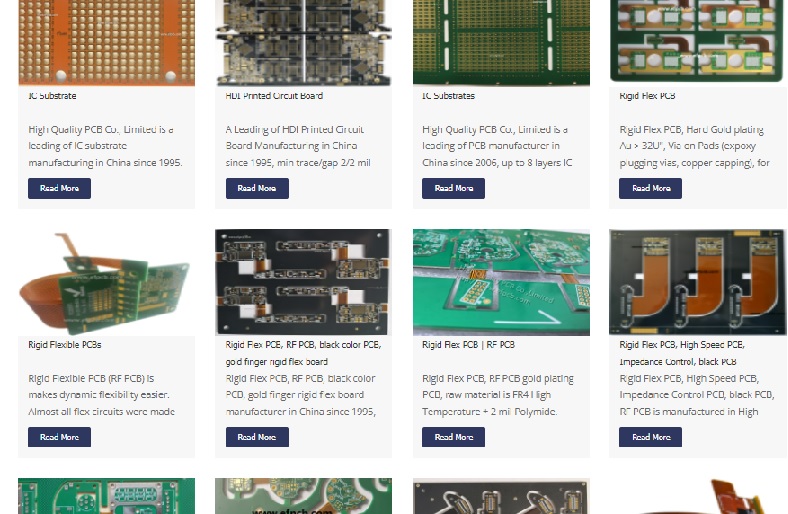

Assortment of Circuit board - Customers with various necessities and prerequisites are being served by the Quick Turn PCB Manufacturer. Consequently, for fulfilling those needs, they offer an expansive scope of PCBs.

Financially savvy - cost-saving is one more significant reason behind the developing interest for this PCB. Prompting lower creation costs, producing time has been decreased basically by embracing the PCB advancements.

Fast time required to circle back - You can find out about it from its name. Conveying arrangements at all measure of time conceivable is the target of this PCB when contrasted with ordinary strategies, independent of the intricacy of the circuit load up. Accomplishing this is the principle focus of makers who are generally focused on their exchange to keep clients from undesirable postponements. In other significant workspaces, the clients can concentrate that way.

Cycle of Quick Turn PCB Assembly

In a Gerber document design, you present it to the PCB maker whenever you have approved and settled the PCB plan. To comprehend your undertaking prerequisites the Quick Turn PCB Manufacturer audits the material and configuration bills prior to sending a statement.

You should support the document and request before they start the collecting and assembling process.

Then, it is guaranteed by the maker that the acquired parts and materials are collected inside the most limited conceivable time.

Making models of sheets is engaged with one of the basic PCB get together methodology. The item's usefulness by the specialists is permitted by the Prototypes in the beginning phases of the plan cycle.

The maker continues to deliver the PCB parts subsequent to finishing the PCB model. Prior to testing the board, the parts are then gathered to guarantee everything is filling in as required.

The accompanying advances can be utilized by the makers at the phase of part collecting:

Blended Assembly - The THA and SMT strategies are joined by makers.

Through-Hole Assembly (THA) - Through-opening parts are mounted and welded by the designers and experts on the unfilled sheets.

Surface-Mount Assembly (SMT) - Using welding materials, electrical parts are affixed subsequent to being mounted on the block stack straightforwardly in this method

The item is conveyed in a bundle to the client after the PCB testing and gathering.

You should consider these elements while choosing a Quick Turn PCB Manufacturer

You should realize that two organizations are not made equivalent while you have various choices for producers. A tremendous contrast in your degree of fulfillment can be settled on by the decision of PCB Company you pick to work with for your undertaking.

Indeed, it need not be convoluted to track down a reasonable contender to get everything done. Following are not many variables to consider while choosing a producer:

Circuit board customization

It's implied that various prerequisites are portrayed by the circuit sheets. So for each client, a one-fits-all approach may not work. Figuring out the customization choices presented by the producer appears to be legit.

Speed

Different conveyance plans are available in PCB gathering and assembling organizations. Conveyance is done in no less than 24 hours by certain producers. Additional time may be taken by others however convey inside the chose time period. Along these lines, you should give appropriate consideration to this area.

You should guarantee that the completion times line up with your different necessities, sending off, or advertising. Additionally, assuming that the organization guarantees short conveyance lead times, hope to pay more.

Experience

You will pick an educated and experienced producer with a demonstrated history in the field on the off chance that you need the best outcomes. The client base should be looked at. A decent sign you are managing the right group is having an extended rundown of fulfilled clients.

Gear

In the most recent cutting edge cycles, innovations, and hardware, the best experts have contributed. With state of the art frameworks and gear, even the most educated specialists and designers should be upheld to fulfill client needs quick and produce excellent sheets.

Quality

The interaction shouldn't think twice about quality while keeping away from delays is the principle point of creation. You should cooperate with a maker that spotlights on the quality perspective. Their tasks should have the conformity to worldwide quality rules and principles.

Fast Turn PCB Applications

Change to PCB standard creation from PCB models is made by the fast turn PCB process.

Creation of PCB Standard

The standard creation and PCB model help is presented by PCB makers. Fabricating the sheets for market applications are engaged with the PCB creation stage.

For getting a high volume of sheets inside the most brief time frame, clients get intrigued once the information and plans are finished by the PCB manufacture organization. The intricacy associated with delivering the circuit sheets doesn't make any difference. Inside the expected time, the end result can arrive at the objective clients with the right PCB producer. Fortifying your upper hand in the business sectors can go far.

If it's not too much trouble, note that the standard creation interaction can be utilized by the clients having the current plans they had recently utilized. To preclude any blemishes in the eventual outcome, they should connect with the PCB model assistance in any case.

PCB Prototypes

Making changes could demonstrate exorbitant in the event that a PCB flops after creation. That is the reason during the beginning phases of this cycle, model sheets are created by the specialists and architects.

For recognizing and amending deserts before a full creation run, the makers are better situated with prototyping.

It really diminishes conveyance time spans and assists accelerate the interaction while the prototyping with handling might seem tedious. First up, when the maker begins decisive creation, it lessens revamps.

Besides, unique PCBs like working models, visual models, verification of-idea, and utilitarian models are utilized by producers use. A precise thought of how the end result will work is given by a creation organizations to the clients with these models. Consequently, the time spent by the producers on clarifications and update is limited and the mystery is killed.

Both for clients as well as producers, Quick Turn PCB is a distinct advantage. It sets aside cash and limits the assembling time. Costly imperfections can be kept away from by the PCB models by distinguishing inconveniences that stay ignored until it's past the point of no return.