Unveiling the Marvels of Rigid-Flexible PCB Manufacturing

Keywords: Rigid Flexible PCB Manufacturer

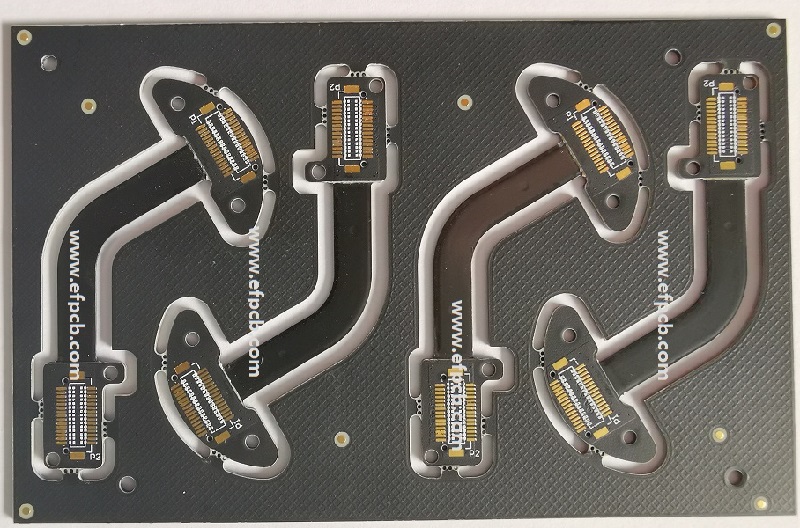

In the dynamic world of electronics, innovation, and adaptability are key drivers that shape the landscape. One technology that has revolutionized the industry is the rigid-flexible printed circuit board (PCB). Combining the benefits of both rigid and flexible substrates, these marvels of engineering provide unprecedented design possibilities for a wide range of electronic devices. In this blog, we will delve into the world of rigid-flexible PCB manufacturing by Rigid Flexible PCB Manufacturer, exploring its significance, applications, and the remarkable advantages it offers to electronics manufacturers.

Rigid-Flexible PCBs

To comprehend the significance of rigid-flexible PCBs, we need to understand their structure and composition. A rigid-flex PCB consists of both rigid and flexible layers that are intricately interconnected, allowing the board to bend, fold, or twist while maintaining excellent electrical and mechanical integrity. This unique construction enables designers to create compact, lightweight, and highly reliable electronic systems.

The Applications of Rigid-Flexible PCBs

Rigid-flex PCBs have found their way into an array of cutting-edge applications across industries. From consumer electronics like smartphones and wearables to medical devices, aerospace systems, and automotive electronics, the versatility of rigid-flex PCBs knows no bounds. Their ability to withstand vibrations, shocks, and extreme temperatures makes them ideal for demanding environments where traditional rigid PCBs fall short. Furthermore, their compact form factor enables seamless integration into smaller, space-constrained devices.

Advantages of Rigid-Flexible PCB Manufacturing

The advent of rigid-flex PCB manufacturing has opened up a realm of possibilities for electronics manufacturers. Let's explore some of the key advantages that have made them increasingly popular:

- Space Efficiency: Rigid-flex PCBs allow for efficient utilization of space, enabling designers to create smaller and lighter devices. By eliminating the need for connectors and cables, they reduce the overall footprint, leading to sleek and compact electronic systems.

- Enhanced Reliability: The seamless integration of rigid and flexible substrates enhances the durability and reliability of electronic systems. Rigid-flex PCBs eliminate the need for multiple interconnects, reducing the risk of failure points and increasing the overall reliability of the device.

- Improved Signal Integrity: Rigid-flex PCBs from Rigid Flexible PCB Manufacturer offer excellent signal integrity due to reduced impedance variations and signal loss. The absence of connectors and shorter interconnect paths minimize signal distortion and noise, resulting in improved performance and data transmission rates.

- Design Flexibility: Rigid-flex PCBs provide designers with unparalleled freedom in terms of shape, form, and functionality. They can be bent, folded, or twisted to fit unconventional layouts, enabling innovative and compact designs that were previously unattainable.

- Cost and Time Savings: Although initial investment costs for rigid-flex PCBs may be higher compared to traditional PCBs, they often result in cost savings in the long run. The elimination of connectors, cables, and assembly steps simplifies the manufacturing process, reducing assembly time and labor costs.

Choosing the Right Rigid-Flexible PCB Manufacturer

When it comes to reaping the benefits of rigid-flex PCBs, selecting the right manufacturer plays a vital role. Here are some factors to consider while choosing a reliable rigid-flex PCB manufacturer:

- Expertise and Experience: Look for a manufacturer with a proven track record in rigid-flex PCB manufacturing. Assess their experience in handling complex designs, materials, and industry-specific requirements. An experienced manufacturer will have the necessary expertise to guide you through the design and manufacturing process effectively.

- Quality Standards: Quality is paramount in the electronics industry. Ensure that the manufacturer adheres to stringent quality standards, such as ISO 9001 and IPC-A-600F. They should have robust quality control measures in place to ensure the production of high-quality rigid-flex PCBs that meet your specifications.

- Manufacturing Capabilities: Evaluate the manufacturer's manufacturing capabilities, including their equipment, technologies, and production capacity. Ensure that they have the necessary infrastructure to handle your project requirements efficiently.

- Design Support: A reliable rigid-flex PCB manufacturer will offer comprehensive design support to help optimize your design for manufacturability. They should have a team of experienced engineers who can provide valuable insights and recommendations to enhance the performance and reliability of your electronic system.

- Material Selection: Different applications may require specific materials with varying characteristics. A reputable manufacturer should offer a wide range of materials and be knowledgeable about their properties, ensuring that you select the most suitable material for your project.

- Prototyping and Production: Consider the manufacturer's prototyping and production capabilities. Quick prototyping turnaround times are crucial for iterative design processes. Additionally, the manufacturer should have scalable production capabilities to meet your volume requirements.

The Future of Rigid-Flexible PCBs

The future of rigid-flex PCBs holds tremendous potential for further advancements and innovation in the electronics industry. We can anticipate the following advancements as technology keeps developing:

Miniaturization: Rigid-flex PCBs will continue to enable the miniaturization of electronic devices. As consumer demand for compact and wearable gadgets increases, manufacturers will strive to create even smaller and lighter designs using rigid-flex PCBs.

- Integration of Advanced Technologies: Rigid-flex PCBs will play a significant role in integrating advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and 5G connectivity. These technologies require flexible and reliable circuitry, making rigid-flex PCBs the ideal choice for seamless integration.

- Flexible Displays and Wearable Electronics: Rigid-flex PCBs will facilitate the development of flexible displays and wearable electronics. With their ability to bend and conform to various shapes, these PCBs will be instrumental in creating flexible screens, smart garments, and wearable healthcare devices.

- Automotive Electronics: The automotive industry will increasingly adopt rigid-flex PCBs for advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle technology. The flexibility and reliability of these PCBs make them ideal for withstanding the harsh conditions and vibrations experienced in the automotive environment.

- Medical and Healthcare Applications: Rigid-flex PCBs will continue to make significant contributions to the medical and healthcare sectors. From implantable devices and wearable health trackers to medical imaging equipment, the integration of rigid-flex PCBs will enhance patient care, improve diagnostics, and enable more personalized healthcare solutions.

Conclusion

The evolution of rigid-flex PCB manufacturing has reshaped the electronics industry, empowering designers to push the boundaries of innovation. The compactness, reliability, and design flexibility offered by these advanced PCBs have paved the way for smaller, lighter, and more sophisticated electronic devices. As technology continues to advance, the demand for rigid-flex PCBs will only grow, driving further advancements in manufacturing techniques and materials. To stay at the forefront of this revolution, electronics manufacturers must embrace the immense potential offered by rigid-flex PCBs and collaborate with experienced Rigid Flexible PCB Manufacturer to unlock new design possibilities and deliver groundbreaking products to consumers worldwide.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact