Unraveling the Wonders of FR4 PCBs: A Deep Dive into the Heart of Electronics

Keywords: FR4 PCB

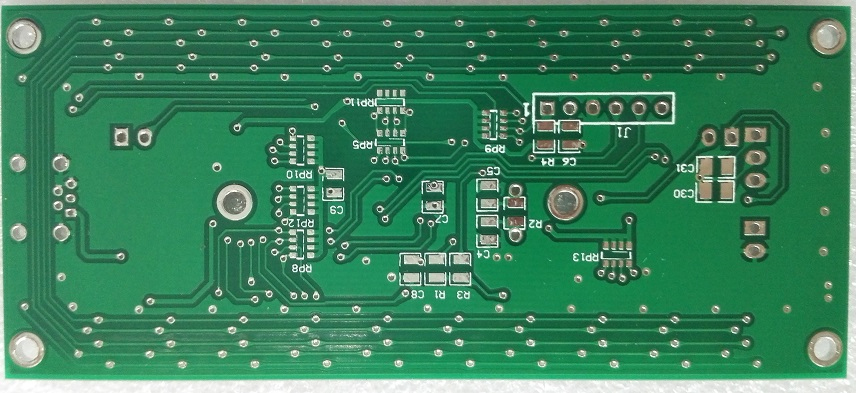

FR4 refers to a flame-retardant, glass-reinforced epoxy laminate material used for manufacturing PCBs. The name itself holds significance, with "FR" standing for flame retardant and "4" indicating the material's grade. The core of FR4 PCB is composed of layers of woven glass fabric impregnated with epoxy resin. This combination results in a robust and durable substrate that forms the backbone of electronic circuits.

Key Features and Advantages of FR4 PCB

Flame Retardant Properties: One of the defining characteristics of FR4 is its ability to resist and inhibit the spread of flames. This is crucial in applications where safety is paramount, such as in aerospace, automotive, and medical devices.

Mechanical Strength: The glass reinforcement in FR4 provides excellent mechanical strength and dimensional stability. This ensures that the PCB can withstand the rigors of manufacturing processes, environmental conditions, and the stresses associated with normal use.

Thermal Stability: FR4 PCB exhibit commendable thermal stability, making them suitable for applications where temperature variations are common. This property helps prevent warping or deformation of the board under different operating conditions.

Electrical Insulation: FR4 is an excellent electrical insulator, preventing unintended electrical contact between different components on the board. This property is essential for maintaining the integrity and reliability of electronic circuits.

Applications

FR4 PCBs find widespread use across various industries due to their versatile properties. Some common applications include:

Consumer Electronics: FR4 PCBs are the backbone of countless consumer devices, from smartphones and laptops to smart home gadgets. Their affordability and reliability make them a preferred choice for mass-produced electronic products.

Industrial Equipment: The robust nature of FR4 PCBs makes them suitable for industrial applications where durability and reliability are critical. They are often found in control systems, power supply units, and automation equipment.

Telecommunications: In the telecommunications sector, FR4 PCBs play a vital role in the construction of routers, switches, and communication modules. Their high-performance characteristics contribute to the efficient functioning of communication networks.

Automotive Electronics: As automotive technology advances, FR4 PCB is increasingly used in vehicle control systems, infotainment systems, and safety features. Their ability to withstand harsh environmental conditions makes them a preferred choice in the automotive industry.