Unleashing the Power of HDI PCB Manufacturing: Revolutionizing Electronics

Keywords: HDI PCB Manufacturing

In the ever-evolving world of electronics, innovation drives progress. As consumer demands for smaller, faster, and more powerful devices increase, the need for advanced printed circuit boards (PCBs) becomes paramount. The production of High-Density Interconnect (HDI) PCBs has revolutionized the industry and made it possible to create small, incredibly effective electronic devices.

In this blog post, we will delve into the fascinating world of HDI PCB manufacturing, exploring its benefits, applications, and the role it plays in revolutionizing the electronics industry.

What is HDI PCB Manufacturing?

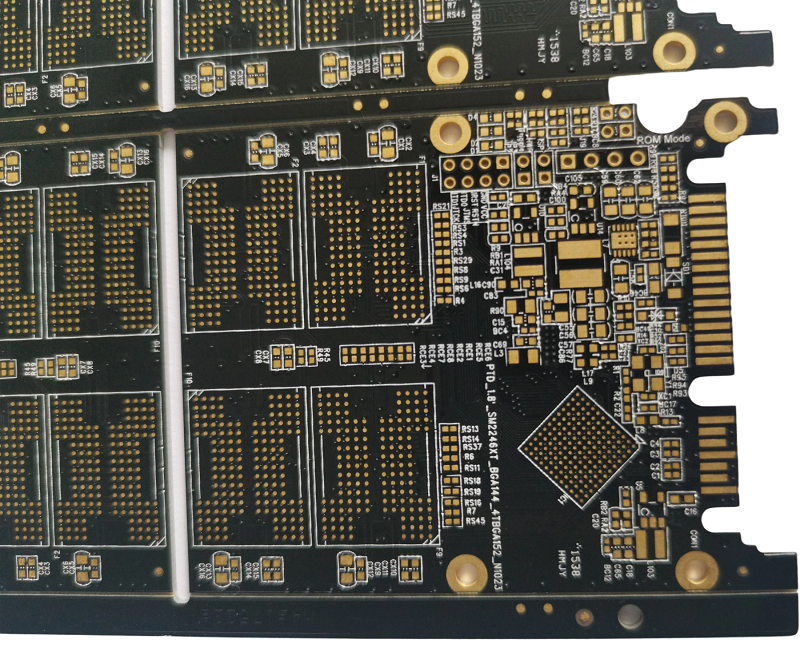

HDI PCB manufacturing represents a significant advancement in the design and fabrication of printed circuit boards. It utilizes advanced technologies and materials to create densely populated PCBs with high component density, finer lines and spaces, and increased functionality. HDI PCBs employ microvias, buried vias, and sequential build-up layers to achieve superior performance in terms of signal integrity, power distribution, and thermal management.

Benefits of HDI PCB Manufacturing:

- Miniaturization: HDI technology allows for the development of smaller and more compact devices, which is crucial for applications where space is limited, such as smartphones, wearables, and medical devices. HDI PCBs enable the integration of more functionality into a smaller footprint, enhancing overall product performance.

- Enhanced Signal Integrity: With finer lines and spaces, HDI PCB manufacturing significantly reduces the length of signal paths, minimizing transmission losses and improving signal integrity. This enables faster data transfer rates, reduced crosstalk, and enhanced overall system performance.

- Increased Density and Component Count: HDI PCBs leverage microvias and buried vias, which provide more routing options and interconnection density. This allows for higher component density and increased functionality, making them ideal for complex electronic systems that require multiple components and high-speed signals.

- Improved Thermal Management: As electronic devices become more powerful, effective thermal management is crucial to ensure reliability and prevent overheating. HDI PCBs employ thermal vias and optimized copper placement to efficiently dissipate heat, enhancing the reliability and lifespan of electronic devices.

- HDI PCB manufacturing has ushered in a new era of possibilities in the electronics industry. By enabling miniaturization, improving signal integrity, increasing component density, and optimizing thermal management, HDI PCBs have become a vital technology for creating smaller, more powerful, and more efficient electronic products.