Understanding the Basics and Benefits of PCBA

Keywords: PCBA China

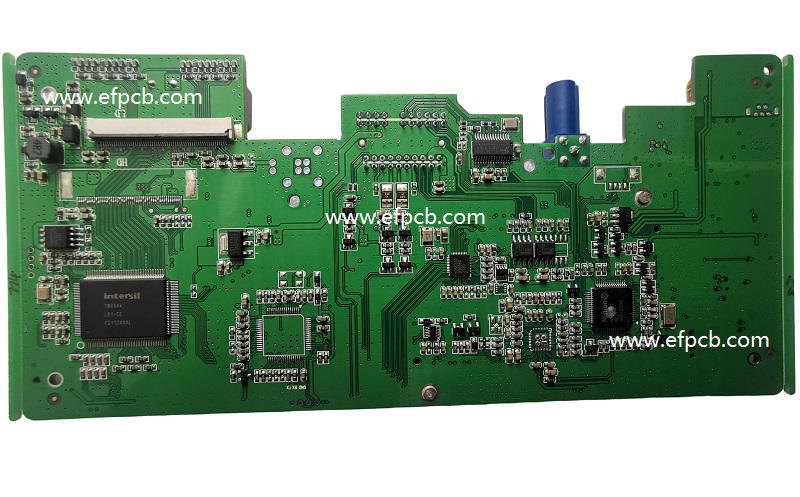

In the realm of modern technology, Printed Circuit Board Assembly (PCBA China) plays a pivotal role in powering our electronic devices. From smartphones to laptops and even smart home appliances, PCBA is the backbone that enables seamless functionality. This blog post aims to provide an in-depth understanding of PCBA, its components, and the benefits it offers in the world of electronics.

What is PCBA?

PCBA, short for Printed Circuit Board Assembly, refers to the process of mounting electronic components onto a printed circuit board (PCB). PCBs are flat boards made of non-conductive materials like fiberglass or composite epoxy that serve as a platform for connecting electronic components using conductive pathways.

Components of PCBA

PCBAs consist of various components, each serving a specific purpose. The primary components include:

- Integrated Circuits (ICs): Also known as microchips, ICs are at the heart of PCBA. These tiny electronic circuits contain millions of transistors and perform specific functions.

- Passive Components: Passive components, such as resistors, capacitors, and inductors, regulate the flow of electricity in a circuit. They do not generate or amplify signals.

- Connectors: Connectors facilitate the connection between different components, allowing the flow of signals and power.

- Diodes: Diodes regulate the flow of electricity, allowing it to pass through only in one direction. They are essential for rectifying AC (alternating current) to DC (direct current).

- Transistors: Transistors act as electronic switches, amplifiers, or current regulators. They are critical for controlling the flow of current in a circuit.

The PCBA Process

The PCBA process involves several steps, including:

- Design: Engineers create a schematic diagram, representing the electronic circuit's design, using computer-aided design (CAD) software.

- PCB Manufacturing: The PCB design is fabricated by etching a copper-clad board, removing unnecessary copper traces, and leaving behind the desired circuit pattern.

- Component Placement: The electronic components are mounted onto the PCB using automated pick-and-place machines or manually by skilled technicians.

- Soldering: Soldering involves bonding the components to the PCB using a soldering iron or a reflow oven. This process ensures electrical and mechanical connections.

- Testing: The assembled PCB is thoroughly tested to ensure its functionality, reliability, and adherence to quality standards. Testing methods include functional testing, in-circuit testing, and automated optical inspection.

Benefits of PCBA

PCBA offers numerous benefits in the field of electronics:

- Compactness and Efficiency: PCBA allows electronic circuits to be densely packed on a single board, reducing the overall size of the device while improving efficiency.

- Improved Reliability: The automated assembly process ensures precise component placement and accurate soldering, resulting in improved reliability and reduced failure rates.

- Cost-Effectiveness: PCBA streamlines the manufacturing process, reducing labor costs and minimizing errors that can lead to costly rework or recalls.

- Faster Production: Automated component placement and soldering significantly accelerate production times, enabling faster time-to-market for electronic devices.

- Quality Control: PCBA involves rigorous testing and inspection, ensuring high-quality products that meet industry standards.

Future Trends in PCBA

PCBA technology continues to evolve, and several trends are shaping its future:

- Miniaturization: With the demand for smaller and more portable devices, PCBA technology is focusing on miniaturization. This trend involves shrinking the size of components and optimizing circuit designs to achieve higher levels of compactness.

- Advanced Materials: The development of advanced materials, such as flexible PCBs and ceramic substrates, is enabling more efficient and reliable PCBA. These materials offer benefits like improved thermal management, higher signal integrity, and increased resistance to environmental factors.

- Surface Mount Technology (SMT): Surface mount technology, which involves mounting components directly onto the surface of the PCB, is gaining popularity due to its space-saving advantages. SMT allows for higher component density and faster assembly times.

- Internet of Things (IoT) Integration: As the IoT continues to expand, PCBA technology is adapting to integrate IoT capabilities seamlessly. This includes incorporating wireless connectivity modules, sensors, and microcontrollers into PCB designs.

- Advanced Testing Techniques: The development of advanced testing techniques, such as automated optical inspection (AOI) and X-ray inspection, is improving the quality control process in PCBA. These techniques enable faster and more accurate detection of defects and ensure the reliability of the assembled PCBs.

Applications of PCBA

PCBA finds applications across various industries and sectors. Some notable applications include:

- Consumer Electronics: PCBA China is widely used in consumer electronics, including smartphones, tablets, laptops, gaming consoles, and home appliances. It enables the integration of complex circuitry and functionality in compact and sleek designs.

- Automotive Industry: PCBA plays a crucial role in the automotive industry, where it is used in vehicle control systems, infotainment systems, GPS navigation, safety systems, and engine control units. It ensures reliable and efficient operation of electronic components in vehicles.

- Industrial Automation: PCBA is integral to industrial automation systems, including programmable logic controllers (PLCs), robotics, and control panels. It enables precise control and communication between various components and systems.

- Medical Devices: PCBA is vital in medical devices such as patient monitoring systems, diagnostic equipment, imaging devices, and implantable devices. It ensures accurate data acquisition, processing, and device functionality in healthcare settings.

- Aerospace and Defense: PCBA is used in aerospace and defense applications, including avionics systems, communication equipment, radar systems, and missile guidance systems. It enables reliable operation in harsh environments and ensures critical functions.

Challenges and Future Outlook

While PCBA brings numerous benefits, it also presents challenges. Some challenges include:

- Design Complexity: As electronic devices become more advanced, PCB designs become increasingly complex, requiring careful consideration of signal integrity, power distribution, and thermal management.

- Component Sourcing and Counterfeit Parts: Ensuring the authenticity and availability of electronic components can be a challenge, as counterfeit parts can compromise the quality and reliability of PCBA.

- Environmental Considerations: The disposal and recycling of electronic waste, including PCBs, require proper handling to mitigate environmental impacts.

Looking ahead, the future of PCBA is promising. Advancements in technology, materials, and manufacturing processes will continue to enhance the performance, reliability, and efficiency of PCBA. The rise of technologies like 5G, artificial intelligence, and edge computing will drive further innovation in PCB designs to meet the demands of emerging applications.

Conclusion

Printed Circuit Board Assembly (PCBA) serves as the backbone of modern electronic devices, enabling their functionality and compactness. Understanding the components and the assembly process is crucial for manufacturers and consumers alike. With its benefits of improved reliability, cost-effectiveness, and faster production, PCBA China continues to revolutionize the electronics industry. As technology advances, PCBA will play an increasingly vital role in powering our devices and driving innovation forward.