The World Is Getting Changed with Gold Fingers

Keywords: Gold Finger PCB, Plating Gold PCB

Today's computerized and mobile-activated environment involves the transmission of signals between many different devices. Communication must take place between two or more circuit boards for each command to be carried out. Without gold fingers, the connecting connections between motherboards, and parts like graphics or sound cards, none of this would be possible in the Gold Finger PCB.

In comparison to older electronics, which often comprised isolated components that were challenging to bring into connection with one another, the technology utilized to convey these signals and orders has made significant strides. The primary processing board reads the operations of one circuit board with gold fingers.

The procedures connected to this cutting-edge technology are used in both the public and private sectors. Signals are sent among numerous equipment and machines in the industrial industry to carry out several operations, many of which cannot be completed by human hands. Many commands are carried out by computer-prompted machinery at auto assembly plants and food packaging facilities, most of which involve circuit boards of one size or another.

How Do Gold Fingers Work?

The columns with gold plating along the connecting edges of printed circuit boards are known as "gold fingers" (PCBs). Gold fingers are used to link a secondary PCB to a computer's motherboard. Other electronic gadgets that communicate via digital signals, including consumer cellphones and smart watches, also employ PCB gold fingers. A PCB's connection points are made of gold due to the alloy's greater conductivity.

For the PCB gold finger plating technique, two kinds of gold are acceptable:

ENIG, or Electroless Nickel Immersion Gold: Although this gold is less expensive and simpler to solder than electroplated gold, it is not ideal for the abrasive impacts of inserting and removing circuit boards due to its soft, thin nature.

Electroplated Hard gold: This gold is thick and solid (hard), making it more suited to withstand the abrasive impacts of prolonged PCB use.

Different circuit boards can communicate with one another thanks to the gold fingers. Signals must go through several connections from the power source to the device or equipment for the command to be carried out.

The signal is sent between one or more circuit boards after you press a command before it is read. The signal is delivered from the PCB-enabled device in your hand to the nearby or distant machine, which in turn receives the signal with its circuit board. For instance, if you push a remote command on a mobile device, the signal is transferred from the mobile device to a distant or nearby machine.

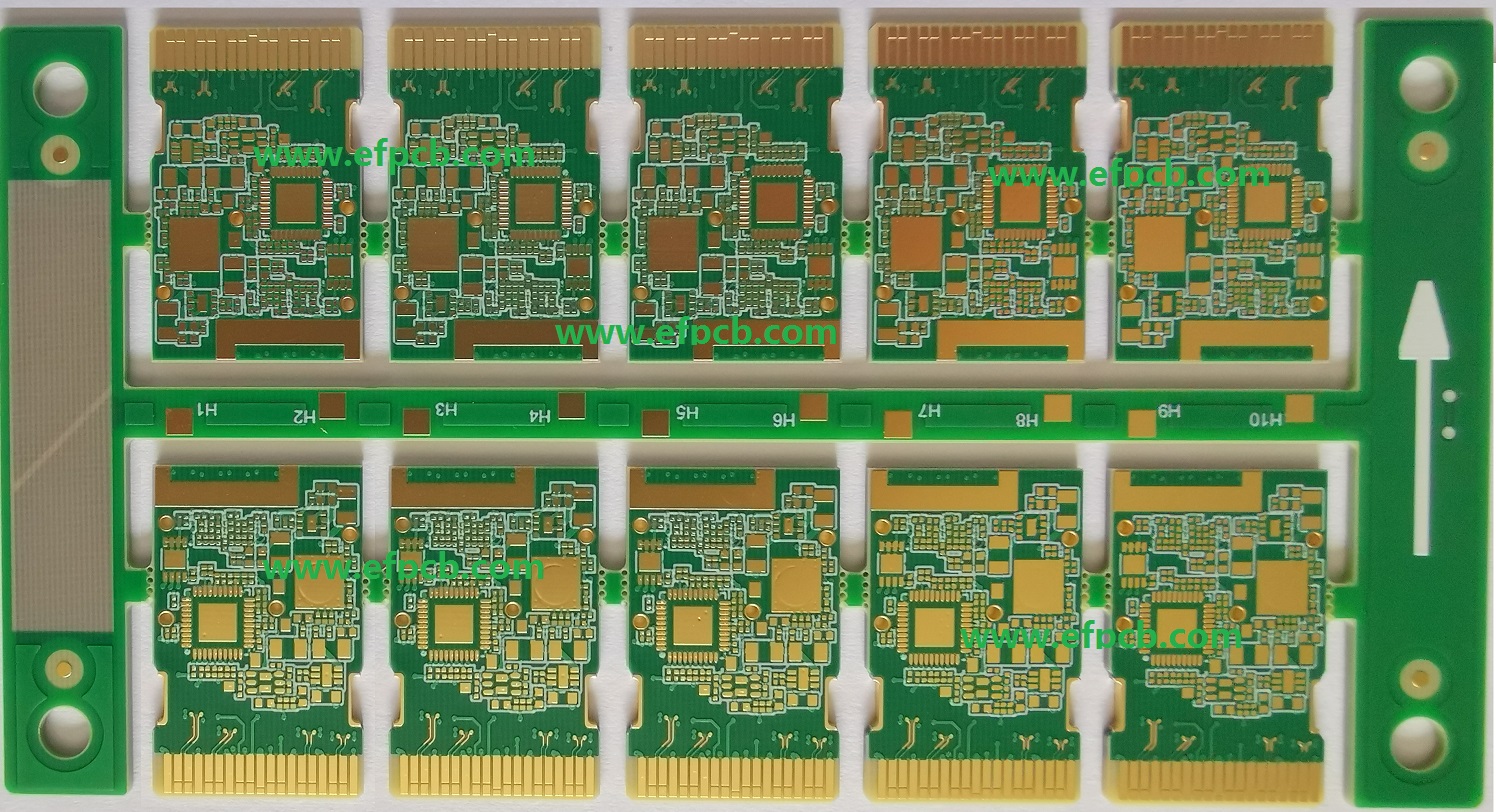

There are several precise stages involved in the Plating Gold PCB fingers. By doing this, it is made sure that every circuit board that leaves the assembly line is prepared to transmit signals accurately.

The plating standards serve to guarantee a flawless match between each circuit board's gold fingers and the corresponding slots on a specific motherboard.

Each PCB is put through a series of inspections and flaw checks to make sure that all of these fingers and slots fit together seamlessly. The results won't be good enough for commercial release if the gold plating on a circuit board isn't smooth enough or doesn't cling to the surface well enough.

The plating procedure must be carried out in stages, starting with the completion of the board's surrounding details, for the PCB gold fingers to come together. Nickel is put on top of the copper when it's time to plate the fingers. The final step is applying the surface finish. After everything has dried, the board is examined closely and put through adhesion tests.

WHERE DO YOU USE GOLD FINGERS PCB?

The connecting connections between two adjacent PCBs are made of gold fingers. The gold serves as a conductor in addition to shielding the connecting edges from wear over time. Gold fingers enable a PCB to be connected, detached, and reconnected up to 1,000 times in a matching slot due to the strength of hard gold at its prescribed thickness.

Gold fingers serve a variety of purposes. Any computer setup will have a variety of peripherals that are connected to the computer using PCB gold fingers. The following list includes some of the most popular applications for gold fingers:

Points of linkage: A female slot, such as a PCI, ISA, or AGP slot, is used to link a secondary PCB to the primary motherboard. The gold fingers in these slots transfer signals from a card within the computer to a peripheral device or vice versa.

Unique adapters: A home computer may have several performance upgrades added thanks to gold fingers. A computer can give improved graphics and high-fidelity sound with auxiliary PCBs that plug perpendicularly into the motherboard. The gold fingers on these cards typically outlive the cards themselves since they are rarely detached and reattached.

External connections: Gold PCB fingers are used to connect the exterior peripherals that have been added to a computer station to the motherboard. The back of the computer tower has specialized slots where speakers, subwoofers, scanners, printers, and monitors are all connected in. In turn, the PCBs that connects to the motherboard are attached to these slots.

Its card must be connected to a power supply for the matching device to function. It's all made feasible by the fingers and matching motherboard slots. Module PCBs are powered by gold fingers, which give the contemporary capability to users of stationary and distant computer equipment.

It is feasible to regularly upgrade the same computer over five or 10 years because of the flexibility of the PCB system, which connects various slots to various types of cards. You may take out the old card from your motherboard and put in the newer one each time a sound or graphics card is upgraded. The PCB gold fingers have remained the standard connection contact during every upgrade.

Gold Finger PCB is also utilized as connecting connections in computerized industrial machines outside the domain of personal computers. Several internal cards are connected to a primary source of electricity by gold fingers in the vast arsenals of automated equipment you might find at a pressing plant or automobile manufacturing. For instance, factory robot arms may be moved in a variety of ways thanks to gold finger cards.