The Rising Power of IC Substrates: Unleashing China Technological Potential Part 2

Key words: IC Substrate, IC Substrates Manufacturing

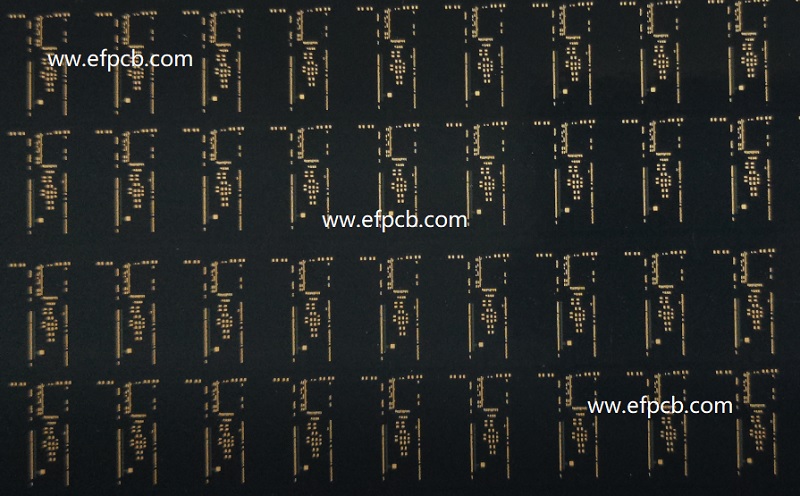

5. Advances in IC Substrate Manufacturing Processes

China has undergone remarkable advancements in IC substrate manufacturing processes in recent years. These developments have positioned China as a prominent player in the global semiconductor industry. The country's growing tech potential has had a transformative effect on the IC substrate market.

1). Multi-Layer and High Density Interconnect (HDI) technology:

Chinese IC substrate manufacturers are actively investing in research and development (R&D) to enhance the production of High Density Interconnect (HDI) substrates. These substrates, made of copper, are equipped with multiple layers of traces and vias, resulting in improved performance. Thanks to technological advancements in HDI, Chinese manufacturers can now produce substrates with finer pitch interconnections. This breakthrough enables the creation of semiconductor devices that are not only more compact but also highly efficient.

2). Laser Via Formation:

A new advance in IC substrate manufacturing is laser via technology. Traditionally, mechanical drilling has been used to create vias in substrates. However, this method has limitations when it comes to achieving smaller via sizes. Laser via lets us make tinier, more precise vias, for denser substrates. This technology has significantly contributed to China's ability to manufacture advanced IC substrates used in a wide range of applications, including consumer electronics, automotive, and telecommunications.

3). Embedded Passive Component Integration:

In the ever-evolving realm of electronics, Chinese IC substrate manufacturers are raising the bar to meet the soaring demand for sleek and integrated devices. Their secret weapon? Embedding passive components right into the substrate itself.

What does this mean for you, the tech savvy consumer? Brace yourself for a revolution in size and weight reduction, as well as an astronomical boost in device performance. How is this sorcery accomplished? By seamlessly incorporating passive components like resistors, capacitors, and inductors into every nook and cranny of the substrate.

But hold on tight, because the perks don't stop there. This mind boggling methodology optimizes signal integrity, slashes power consumption, and fortifies the reliability of those darling semiconductor devices. Who knew that such tiny, hidden heroes.

4). Advanced Material Selection:

In the fast-paced world of the China IC substrate industry, there's a relentless pursuit of excellence. Manufacturers are diving headfirst into the realm of advanced materials, harnessing their power to revolutionize IC substrate performance. Picture this: low loss dielectrics, high temperature laminates, and high thermal conductivity materials all working together as a dream team. With these cutting-edge additions, Chinese manufacturers are unlocking a whole new level of greatness.

Signal transmission? Oh, it's on point. Thermal dissipation? Absolutely topnotch. Reliability? It's off the charts. These materials are the secret ingredients behind the creation of IC substrates that can stand strong against higher frequencies, push the boundaries of power densities, and even brave the most unforg.

In the realm of Chinese manufacturing, groundbreaking strides have been achieved in the production of substrates. They have masterfully honed their expertise, elevating signal integrity and revolutionizing electrical performance. Picture this: Multilayer and High Density Interconnect (HDI) substrates have emerged as game changers, empowering the design of semiconductor devices that are not only more compact but also incredibly efficient. The marriage

Laser tech revolutionized via production, creating smaller, precise ones. Now, higher density substrates meet industry demands in consumer electronics, automotive, and telecom.

Chinese manufacturers embed passive components directly into substrates to create smaller, integrated electronic devices. This eliminates discrete components, reducing size and weight while improving performance. By incorporating passive components within the substrate, signal integrity is optimized, power consumption is reduced, and overall reliability of semiconductor devices is enhanced.

Chinese manufacturers have improved IC substrate manufacturing by exploring advanced materials. They utilize low-loss dielectrics, high temperature laminates, and high thermal conductivity materials. This leads to enhanced performance and durability. As a result, the substrates can withstand higher frequencies, power densities, and harsh operating conditions.

6. China is a Leader of IC Substrates Innovation

Step right into the enchanting integrated circuit (IC) substrate industry world in China, brace yourself for an extraordinary spectacle of mind boggling advancements and unparalleled contributions by Chinese companies. They have shattered boundaries, revolutionizing the marriage between chips and circuit boards, leaving expectations in pieces. Get ready to witness a whirlwind of groundbreaking innovations that have set the industry ablaze, propelling it towards uncharted realms of growth and triumph. Dear companions, behold a future adorned with awe inspiring discoveries and game changing victories, all fueled by China's unwavering dedication and indomitable spirit. Prepare for an exhilarating journey beyond imagination!

1). Rise of Chinese IC Substrate Manufacturers.

The realm of IC substrate manufacturing has witnessed a groundbreaking disruption thanks to Chinese companies. These emerging players have not only surpassed established industry giants but have also left a lasting impact on the global market. Their secret recipe for success? A strategic blend of relentless investment in research, infrastructure, and top-notch talent, paving the way for a

2). Technological Advancements.

When it comes to cutting-edge technological advancements in IC substrate manufacturing, Chinese companies spearhead the race. They are at the forefront of creating top-notch IC substrates that surpass expectations, thanks to their ingenious utilization of innovative materials, ingenious designs, and cutting-edge processes. These visionary companies specialize in a multitude of areas, from HDI and FCBGA to embedded substations.

3). Collaboration with Industry Giants

China companies in the global IC substrate market form alliances with industry leaders, fueling knowledge exchange and technology dissemination. These partnerships unlock cutting-edge manufacturing resources, propelling Chinese enterprises to dominance in the vibrant IC substrate industry.

4). Domestically Driven Demand

The Chinese semiconductor industry is booming at lightning speed, fueled by the skyrocketing demand for electronic devices within its domestic market. And guess what? This growth has sparked a revolution in the Chinese IC substrate manufacturing sector. Why, you ask? Well, it's all about localizing supply chains and reducing reliance on those foreign suppliers that have held the reins for so long. As a result, the clamor for top-notch IC substrates from Chinese companies has reached unprecedented levels.

The China semiconductor industry is booming due to the high demand for electronic devices in the country. This growth has led to unprecedented success for Chinese IC substrate manufacturers.

5). Market Expansion and Global Influence

China companies excel in meeting local demand and expanding globally. They fearlessly enter international markets, establishing themselves as leaders in the IC substrate supplies field. Their unwavering commitment to innovation sets them apart, delivering unmatched quality and value. Through this dedication, they gain trust and achieve success.