The Importance of UL PCBs in Modern Electronic Devices

Keywords: Canada UL PCB

PCB stands for Printed Circuit Board, and it is an essential part of every electronic device we use. The technology of PCBs has evolved over the years, and one of the latest advancements is the Canada UL PCB.

UL stands for Underwriters Laboratories, which is an independent testing organization that sets safety standards for electrical devices. UL PCBs are PCBs that comply with UL's safety standards, ensuring that they are safe and reliable for use in electronic devices. In this blog post, we will explore what UL PCBs are, their advantages, and why they are essential in modern electronic devices.

What is a UL PCB?

A UL PCB is a printed circuit board that complies with the safety standards set by Underwriters Laboratories. UL is an independent testing organization that conducts safety tests on electrical devices, including printed circuit boards. UL tests PCBs to ensure that they are safe and reliable for use in electronic devices.

UL PCBs must meet specific safety standards, including flammability, electrical safety, and mechanical safety. The PCBs must also pass tests for environmental conditions, including temperature, humidity, and chemical exposure.

Advantages of UL PCBs

There are several advantages to using UL PCBs in electronic devices. Some of the benefits of UL PCBs include:

- Safety: UL PCBs are designed to meet specific safety standards, making them safe and reliable for use in electronic devices. They are less likely to cause accidents or malfunction, reducing the risk of injury or damage to property.

- High-quality: UL PCBs are made to a high standard, ensuring that they are of high quality and will perform well in electronic devices. This means that they are less likely to fail or malfunction, reducing the need for repairs or replacements.

- Reliability: UL PCBs are designed to be reliable, ensuring that electronic devices using them will function correctly. This means that they are less likely to fail, reducing downtime and increasing productivity.

- Compliance: UL PCBs comply with specific safety standards, ensuring that they meet industry regulations and guidelines. This is important for electronic devices used in sensitive industries such as healthcare, aerospace, and defense.

Why are UL PCBs essential in modern electronic devices?

UL PCBs are essential in modern electronic devices for several reasons. First, electronic devices are becoming increasingly complex and sophisticated, requiring more advanced PCBs to function correctly. UL PCBs are designed to meet these complex requirements, ensuring that electronic devices using them will perform reliably and safely.

Second, electronic devices are becoming more critical in our daily lives, with many of them being used in the healthcare, defense, and aerospace industries. In these industries, safety, and reliability are critical, and UL PCBs play a crucial role in ensuring that electronic devices meet these requirements.

Third, electronic devices are becoming more compact, with smaller and smaller components being used. This means that PCBs are becoming more complex, with more connections and smaller traces. UL PCBs are designed to meet these requirements, ensuring that they are safe and reliable despite their complexity.

Fourth, electronic devices are being used in harsher environments, such as extreme temperatures, humidity, and exposure to chemicals. UL PCBs are designed to meet these environmental conditions, ensuring that they will function correctly in these environments.

In summary, UL PCBs are essential in modern electronic devices because they provide safety, high quality, reliability, and compliance with industry regulations. They are designed to meet the complex requirements of modern electronic devices and to function correctly in harsh environments. With the increasing importance of electronic devices in our daily lives, UL PCBs play a crucial role in ensuring that these devices are safe and reliable.

Canada UL PCB also plays a crucial role in reducing the risk of fire in electronic devices. The flammability standards set by UL ensure that UL PCBs are less likely to ignite or contribute to the spread of fire in electronic devices. This is important because electronic devices can be a significant fire hazard if they malfunction or fail.

UL PCBs also help to reduce the environmental impact of electronic devices. UL PCBs are designed to be more energy-efficient, reducing the amount of energy required to power electronic devices. This helps to reduce greenhouse gas emissions and lower energy costs.

UL PCBs also help to reduce the amount of waste generated by electronic devices. Because UL PCBs are designed to be reliable and long-lasting, electronic devices using them are less likely to need repairs or replacements. This helps to reduce the amount of electronic waste generated by discarded or outdated electronic devices.

UL PCBs are also essential for companies that manufacture electronic devices. By using UL PCBs in their products, companies can demonstrate their commitment to safety and quality, which is essential for building consumer trust and confidence.

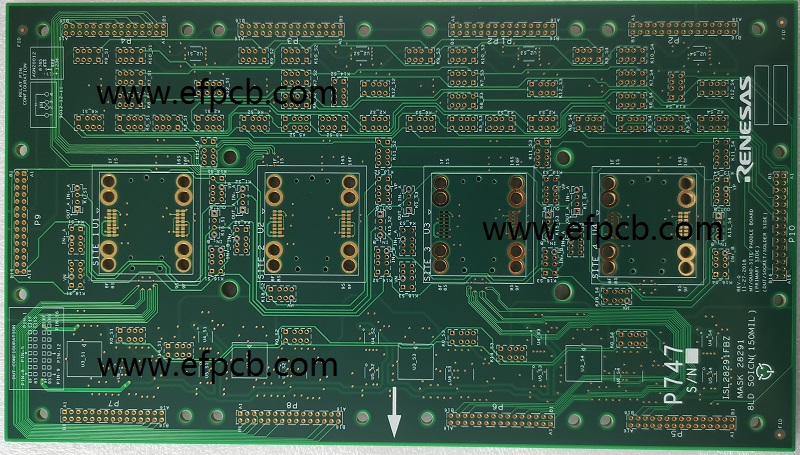

UL PCBs are available in various types, including single-sided, double-sided, and multi-layer PCBs. The choice of UL PCB type depends on the complexity and requirements of the electronic device.

- Single-sided UL PCBs are the simplest and most common type of UL PCB. They have copper traces on only one side of the PCB, and components are mounted on the same side. Single-sided UL PCBs are suitable for less complex electronic devices that require only a few components.

- Double-sided UL PCBs have copper traces on both sides of the PCB, and components can be mounted on both sides. This type of UL PCB is suitable for more complex electronic devices that require more components and connections.

- Multi-layer UL PCBs have several layers of copper traces, which are sandwiched between layers of insulating material. This type of UL PCB is suitable for highly complex electronic devices that require many components and connections.

When choosing a UL PCB, it is essential to consider the specific requirements of the electronic device, such as the number of components, the complexity of the circuit, and the environmental conditions.

UL PCBs are manufactured using various techniques, including through-hole technology and surface mount technology (SMT). Through-hole technology involves drilling holes through the PCB and inserting components through the holes. This technique is suitable for larger components and allows for easy testing and repair of the PCB.

Surface mount technology (SMT) involves mounting components directly onto the surface of the PCB. This technique is suitable for smaller components and allows for more compact PCB designs. SMT also allows for the automated assembly of PCBs, which is more efficient and cost-effective than manual assembly.

In conclusion, UL PCBs are an essential part of modern electronic devices. They provide safety, high quality, reliability, compliance, and environmental benefits. With the increasing complexity and importance of electronic devices, Canada UL PCB plays a crucial role in ensuring that these devices are safe, reliable, and environmentally sustainable. Whether you are a consumer, manufacturer, or industry professional, UL PCBs are an essential technology that you should be aware of and understand.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5IC Substrate | Comprehensive Guide (2021)

- 6Top HDI PCB Manufacturers (2024)

- 7How to Make mSAP PCB?

- 8The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 9Top 10 IC Substrate Fabricators (2024)

- 10Top 10 Flexible PCB Factories in 2025

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact