The Importance of Printed Circuit Boards in Today's World

Keywords: Printed Circuit Board Manufacturer

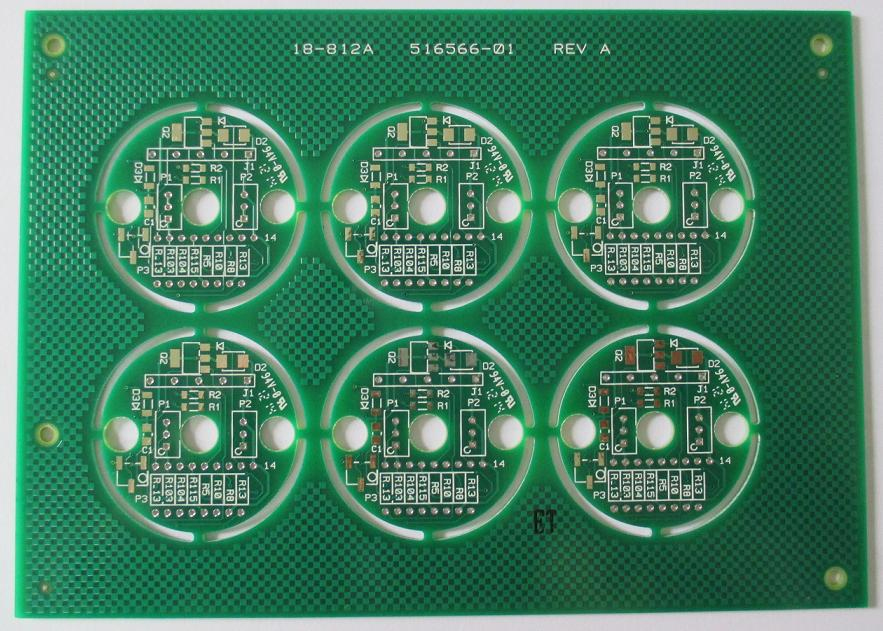

PCBs, or printed circuit boards, are a crucial component of contemporary electronics. They are used in everything from computers and smartphones to cars and medical devices. PCBs allow engineers to create complex electronic systems that would be impossible to build with traditional wiring. PCBs from Printed Circuit Board Manufacturer are made up of a substrate, which is a material that provides a base for the circuit, and a conductive material, which conducts electricity. The conductive material is usually copper, which is etched onto the substrate to create the circuit pattern.

There are many different types of PCBs, each with its advantages. Some of the most common types of PCBs include single-layer PCBs, double-layer PCBs, multilayer PCBs, and flexible PCBs.

- The most basic sort of PCBs are single-layer PCBs. They have only one conductive layer, which is etched onto one side of the substrate. Single-layer PCBs are the least expensive type of PCB, but they are also the least complex.

- Double-layer PCBs have two conductive layers, which are etched onto opposite sides of the substrate. Double-layer PCBs are more expensive than single-layer PCBs, but they can be used to create more complex circuits.

- Multilayer PCBs have more than two conductive layers. Between a few and hundreds of layers may exist. Multilayer PCBs are the most expensive type of PCB, but they can be used to create the most complex circuits.

- Flexible PCBs are made from a flexible substrate, such as a polymer. Flexible PCBs are often used in applications where space is limited, such as in mobile phones and medical devices.

PCBs are an essential part of modern electronics. They allow engineers to create complex electronic systems that would be impossible to build with traditional wiring. PCBs are used in a wide variety of industries, including consumer electronics, automotive, medical, and aerospace.

The Future of Printed Circuit Boards

The demand for PCBs is expected to grow in the coming years. This is due to the increasing use of electronics in all aspects of our lives. As electronics become more complex, the need for PCBs that can handle the increased complexity will also grow.

Several trends are expected to shape the future of PCBs. One trend is the increasing use of multilayer PCBs. Multilayer PCBs allow engineers to create more complex circuits in a smaller space. This is important as electronics become more miniaturized.

Another trend is the increasing use of flexible PCBs. Flexible PCBs are used in applications where space is limited, such as in mobile phones and medical devices. As electronics become smaller and more portable, the demand for flexible PCBs is expected to grow.

Finally, the increasing use of automation in the PCB manufacturing process is another trend that is expected to shape the future of PCBs. Automation will help to improve the efficiency and quality of PCB manufacturing. This will help to reduce costs and make PCBs more affordable.

The PCB Manufacturing Process

The PCB manufacturing process is a complex and multi-step process. It begins with the design of the PCB, which is created using computer-aided design (CAD) software. The CAD software allows engineers to create a detailed model of the PCB, including the layout of the conductive traces and pads.

Once the PCB design is complete, it is sent to Printed Circuit Board Manufacturer. The manufacturer will use the CAD design to create a photo mask, which is a negative image of the PCB. The photo mask is used to expose the copper foil on the substrate, which creates the conductive traces and pads.

After the copper foil is exposed, it is etched away to remove the unwanted copper. The etched PCB is then plated with a layer of copper, which fills in the conductive traces and pads.

The next step is to drill holes in the PCB for the mounting holes and vias. Vias are holes that connect the conductive layers of the PCB.

After the holes are drilled, the PCB is cleaned and inspected. The PCB is then coated with a solder mask, which is a protective layer that prevents the solder from flowing onto the non-conductive areas of the PCB.

The final step is to silkscreen the PCB. Silk-screening is a process of printing text and graphics on the PCB. The silkscreen is used to identify the components and to provide other important information.

Once the PCB is silkscreened, it is ready for assembly. The assembly process involves mounting the components on the PCB and soldering them in place.

After the components are soldered, the PCB is tested to ensure that it meets the required specifications. The PCB is then ready for use.

The PCB manufacturing process is a complex and multi-step process. However, it is a critical step in the development of electronic products. By following the steps outlined above, PCB manufacturers can create high-quality PCBs that meet the needs of their customers.

The Benefits of Using a Printed Circuit Board Manufacturer

There are many benefits to using a PCB manufacturer. Some of the benefits include:

- Expertise: PCB manufacturers have the expertise and experience to create high-quality PCBs.

- Speed: PCB manufacturers can typically produce PCBs much faster than in-house production.

- Cost: PCB manufacturers can often produce PCBs at a lower cost than in-house production.

- Quality: PCB manufacturers have the resources to ensure that the PCBs they produce meet the required specifications.

If you are looking for a high-quality PCB, then you should consider using a PCB manufacturer. By working with a PCB manufacturer, you can be sure that your PCBs will meet your needs.

How to Choose a PCB Manufacturer

When choosing a PCB manufacturer, there are a few factors that you should consider. Some of the factors to consider include:

- Experience: The PCB manufacturer should have experience in producing the type of PCBs that you need.

- Quality: The PCB manufacturer should have a good reputation for producing high-quality PCBs.

- Price: The PCB manufacturer should be able to provide you with a competitive price.

- Turnaround time: The PCB manufacturer should be able to produce your PCBs promptly.

By considering these factors, you can be sure to choose a PCB manufacturer that can meet your needs.

Conclusion

Printed circuit boards from Printed Circuit Board Manufacturer are an essential part of modern electronics. They are used in a wide variety of industries and are expected to become even more important in the future. The trends that are shaping the future of PCBs include the increasing use of multilayer PCBs, flexible PCBs, and automation.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact