The Importance of PCBs in Modern Electronics

Keywords: PCB China

Printed Circuit Boards (PCBs) are an integral part of modern electronics. PCB China is used to connect different electronic components in a device and facilitate their communication with each other. PCBs have replaced traditional wiring methods, making electronic devices more compact, reliable, and efficient. In this blog post, we will discuss the importance of PCBs, the manufacturing process, and the different types of PCBs.

Importance of PCBs

The significance of PCBs cannot be overstated. PCBs are used in almost all electronic devices, ranging from smartphones to supercomputers. PCBs provide a stable and reliable platform for the different electronic components to work together, allowing for efficient and error-free communication. PCBs also reduce the complexity of wiring and assembly, making the manufacturing process faster and more cost-effective.

PCBs have also made it possible to create smaller and more compact electronic devices. The miniaturization of electronic components has made it possible to create powerful devices that can fit in the palm of your hand. PCBs have enabled this miniaturization by providing a stable platform for the components to be mounted on.

The Manufacturing Process

The manufacturing process for PCBs involves several steps, each of which is critical to ensure the final product is of high quality. The following are the steps involved in the manufacturing of PCBs:

- Design: The first step in manufacturing PCBs is designing the circuit. Software for computer-aided design (CAD) is used to create the circuit. The design includes the placement of electronic components and the layout of the circuit.

- Printing the Circuit: The next step is to print the circuit onto a copper-clad board. This is done using a process called etching, which involves using chemicals to remove the unwanted copper from the board. The circuit is created by the copper that is still on the board.

- Drilling Holes: After the circuit has been printed, holes are drilled in the board where the electronic components will be placed. The holes are then plated with a conductive material to ensure that the components are electrically connected to the circuit.

- Component Placement: Once the holes have been drilled and plated, the electronic components are placed on the board. This is done using automated equipment that ensures that the components are placed accurately.

- Soldering: After the components have been placed on the board, they are soldered in place. Soldering involves heating the connections between the components and the board to create a permanent electrical connection.

- Testing: The final step in the manufacturing process is testing the board to ensure that it is functioning correctly. This is done using automated equipment that checks the electrical connections and the performance of the board.

Types of PCBs

PCBs come in different types, each designed for specific applications. The following are the different types of PCB China:

- Single-Sided PCBs: Single-sided PCBs have only one layer of copper and are the simplest type of PCB. They are commonly used in low-cost applications such as calculators and toys.

- Double-Sided PCBs: Double-sided PCBs have two layers of copper, with electronic components placed on both sides. They are used in more complex applications such as computer motherboards and power supplies.

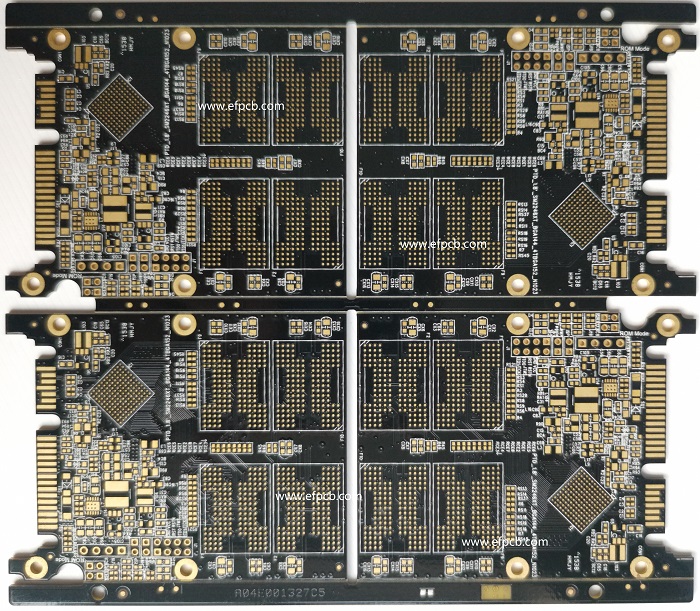

- Multi-Layer PCBs: Multi-layer PCBs have multiple layers of copper and are used in high-density applications such as smartphones and tablets. They can have up to 16 layers of copper.

- Rigid PCBs: Rigid PCBs are made from rigid materials such as fiberglass and are used in applications where the board needs to be stiff and strong. They are frequently employed in aeronautical and automotive applications.

- Flex PCBs: Flex PCBs are made from flexible materials such as polyimide and are used in applications where the board needs to be flexible. They are commonly used in medical devices, cameras, and wearables.

- Rigid-Flex PCBs: Rigid-flex PCBs combine the strength of rigid PCBs with the flexibility of flex PCBs. They are used in applications where the board needs to be both strong and flexible, such as smartphones and laptops.

- High-Frequency PCBs: High-frequency PCBs are designed for applications that require high-speed data transfer, such as telecommunications and networking equipment. They are made from specialized materials that have low dielectric constant and loss tangent.

PCBs are an essential component in modern electronics, and their manufacturing process and different types have revolutionized the way electronic devices are made. The use of PCBs has made electronic devices smaller, more reliable, and more cost-effective. PCBs are used in almost all electronic devices, and their importance cannot be overstated.

Furthermore, the use of PCBs has helped to reduce the size and weight of electronic devices, making them more portable and convenient to use. For example, smartphones have become an essential part of our lives, and the use of PCBs has made it possible to create compact devices with powerful processors, high-resolution displays, and multiple cameras.

PCBs have also made electronic devices more reliable and durable. The use of automated equipment in the manufacturing process ensures that the components are placed accurately, and the connections are soldered correctly. This reduces the likelihood of errors and faults, making the devices more reliable. Additionally, the use of rigid PCBs in applications such as automotive and aerospace ensures that the devices can withstand extreme temperatures, shock, and vibration.

Moreover, PCBs have reduced the cost of manufacturing electronic devices. The use of automated equipment in the manufacturing process reduces labor costs and ensures that the process is faster and more efficient. Additionally, the use of PCBs has eliminated the need for traditional wiring methods, reducing the cost of materials and assembly.

However, there are some challenges associated with the use of PCBs. For example, the disposal of PCBs can have a significant impact on the environment. PCBs contain hazardous chemicals, such as lead and mercury, which can leach into the soil and water if not disposed of correctly. Therefore, it is essential to dispose of PCBs in an environmentally friendly manner to prevent harm to the environment and human health.

In conclusion, PCB China has revolutionized the way electronic devices are made and used. The manufacturing process of PCBs involves several critical steps, and different types of PCBs are available for specific applications. PCBs have made electronic devices smaller, more reliable, and more cost-effective. However, the disposal of PCBs can have a significant impact on the environment, and it is essential to dispose of them in an environmentally friendly manner. PCBs will continue to play a critical role in the development of modern electronics, and their importance will only increase in the future.

PCBs have played a critical role in the development of modern electronics. The manufacturing process of PCBs involves several critical steps, including designing the circuit, printing the circuit, drilling holes, placing components, soldering, and testing. PCBs come in different types, each designed for specific applications. The different types of PCBs include single-sided PCBs, double-sided PCBs, multi-layer PCBs, rigid PCBs, flex PCBs, rigid-flex PCBs, and high-frequency PCBs. Understanding the importance of PCBs and the different types available can help manufacturers and designers choose the right PCB for their applications.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top HDI PCB Manufacturers (2024)

- 6IC Substrate | Comprehensive Guide (2021)

- 7Top 10 Flexible PCB Factories in 2025

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact