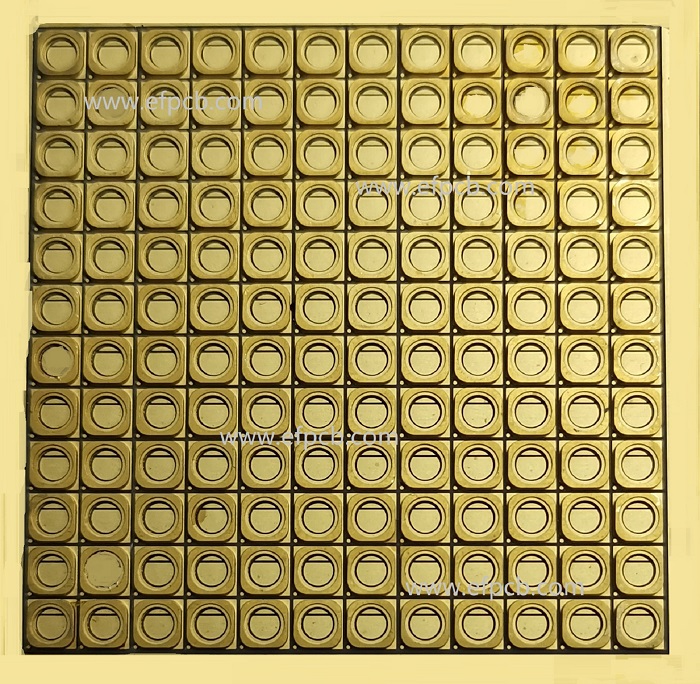

The Ceramic Substrates is A Technological Marvel in PCBs

Keywords: ceramic substrate

A PCB's substrate is the material on which the circuit components are mounted and interconnected. Traditionally, fiberglass-reinforced epoxy resin (FR-4) has been the go-to choice for PCB substrates due to its cost-effectiveness and ease of manufacturing. However, as electronic devices become more sophisticated, the limitations of FR-4 in terms of thermal performance and reliability have become apparent.

Ceramic substrates, composed of materials like alumina (Al2O3) or aluminum nitride (AlN), have stepped in to address these limitations. These materials offer exceptional thermal conductivity, mechanical strength, and electrical insulation, making them ideal for applications where high-performance and reliability are paramount.

Advantages of Ceramic Substrates in PCBs

Thermal Conductivity

One of the most significant advantages of ceramic substrates is their outstanding thermal conductivity. This property allows for efficient dissipation of heat generated by electronic components, preventing overheating and ensuring the reliability of the device.

Mechanical Strength

Ceramic substrates exhibit excellent mechanical strength and stability. This makes them well-suited for applications in harsh environments where the PCB may be subjected to physical stress or vibration.

Miniaturization

The demand for smaller and more compact electronic devices has driven the need for miniaturized components and PCBs. Ceramic substrates, with their high dielectric strength, enable the creation of densely packed circuits without compromising on performance.

Reliability and Longevity

Ceramic substrates contribute to the overall reliability and longevity of electronic devices. Their ability to withstand high temperatures, chemical exposure, and mechanical stress ensures that PCBs operate consistently over extended periods.

High-Frequency Applications

In applications requiring high-frequency signals, such as RF (radio frequency) and microwave circuits, ceramic substrates excel. Their low loss tangent and stable electrical properties at elevated frequencies make them the substrate of choice for these demanding applications.

As electronic devices continue to evolve, the role of ceramic substrates in PCBs becomes increasingly crucial. Their exceptional thermal conductivity, mechanical strength, and reliability make them a game-changer in industries ranging from consumer electronics to aerospace. As we delve deeper into the era of high-performance computing and connectivity, the integration of ceramic substrates in PCB design is set to play a pivotal role in shaping the future of electronic technology.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact