Test Your Knowledge about the First Article Inspection of PCBA

Keywords: PCBA China, PCBA Assembly China

Its first article is also inspected when a printed circuit board is built but not for taste. The group of boards or first board built is considered the first article after a PCBA China contract manufacturer sets up the necessary assembly processes and your design. In the manufacturing process of your circuit boards, this first article is a crucial step. This is because it will be inspected very closely by the manufacturer for any potential manufacturing issues and accuracy. This article will depict what you manufacturer must look at in the first article of the PCB and how you get benefitted ultimately.

As compared to other types of inspection, like SPI, AOI, visual inspection, and X-ray in the mind of people who are involved in the industry of Manufacturing Printed Circuit Board (PCB) Assembly, First Articles Inspections (FAI) are less common generally. An outside inspection might be resisted by many SMT assembly or PCB assembly suppliers who are unaware of the requirement of the customer, especially when the customer is from overseas.

Outlining your PCB assembly requirement is even more crucial for an inspection of the first article in your documentation of fabrication drawing. You must also verify whether the manufacturer of the circuit board assembly has the capability to meet your requirement and conduct the FAI work. You can have a better understanding of the requirement in more detail. Of course, the expectation of how and when the qualities of PCB assemblies will be evaluated by you must be set by the fabrication drawing. The pushback from the selected supplier is prevented by this. For implying the significance of the PCBA yield in high-volume PCB assembly projects, an acceptable defects rate can also be set.

Do you Need First Articles Inspection if You Have Any Sample of Approved PCB Assembly in China?

A similar purpose to a PCBA pre-production sample can be served by the first article of the printed circuit board assembly (PCBA). Indeed, a kind of device sample is the first article itself. Your expectation from mass production from your turnkey PCB assembly supplier is reflected by both an approved first article and a PCBA pre-production sample.

For assessing your understanding of your SMT assembly supplier about your requirements and clarifying expectations, approving a PCBA sample before production begins can be of great help. For reference both at QC stations and on the assembly production line, pre-production samples can be kept as internal gold standards once approved.

Engineers of the engineering team in the PCB assembly factory usually custom make samples of PCBA Pre-production. On the assembly production line, the first articles are made which may be in the factory of your previous supplier or in the same assembly factory.

Significance of First Article Inspection Process in the PCB

It serves two crucial purposes when a contract manufacturer builds a first article circuit board.

Producing the first article board that will be used for inspection is the first. Validating that nothing has been left out and all of the documented requirements have been met on this first build is the inspection is necessary.

You must know that not only when a revision is being made to an existing design but also for the production of a new PCBA Assembly China design, the first article is built. Verifying that the board being built is exactly what is expected is crucial in each case.

Establishing the process of record (POR) is the second purpose of the first article for the production of the board. It must be replicated throughout the regular board production once the POR is established. This guarantees that according to the same process, each board is built. Thus, every board will work the same way.

Unless the board is being revised, the POR cannot be changed as part of the copy exact methodology. For validating the new changes being made, a new first article would be required at that point.

What your manufacturer must do during the First Article Inspection?

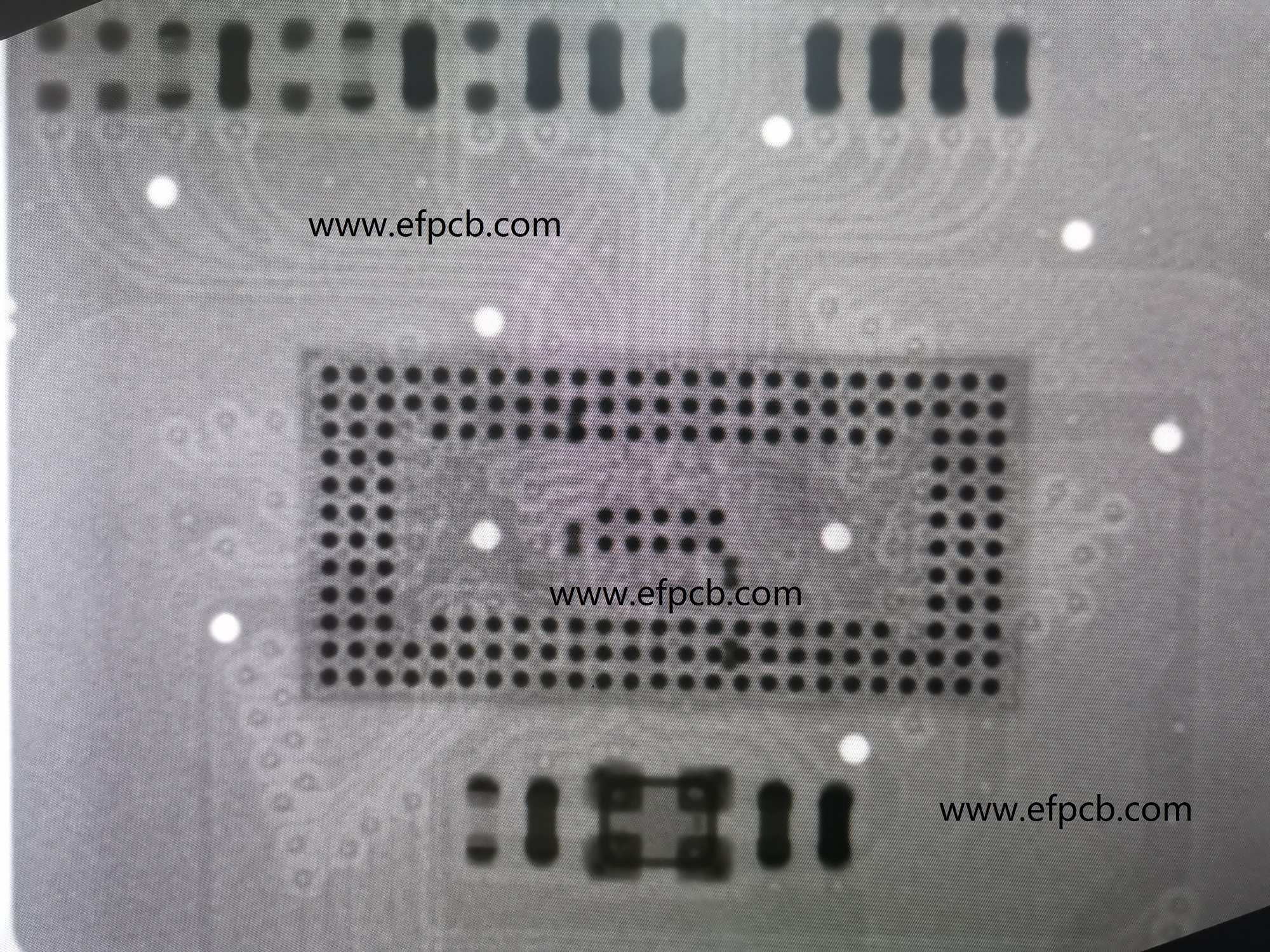

A very thorough process is the inspection of a first article circuit board build. It must be validated b your manufacturer that 100% of all of your documented needed have been met on this first build. The manufacturer must be looking at the following very closely to do that:

Manufacturing errors: for tracing corrections and changes, any issues arising during the assembly process must be inspected. These compromises soldering problems, issues of component insertion, etc.

Measurable attributes: All of the measurable board attributes, such as resistance, voltages, or dimensions must be recorded and measured. Against the design specifications, these values are then verified.

Documentation clarity: Often the confusion source is documented requirements that are unclear in circuit board manufacturing. Between what was expected and the documented requirements, the first article inspection will reveal any discrepancies.

Supplier validation: For matching their specifications, materials, and parts that are installed on the board should be inspected. These include wiring harnesses, sheet metal, cables, and subassemblies.

For finding any possible issue in the first article, these inspection measures are designed before regular production is begun. Before going on to full production, the board must go through some corrective actions if any issues are found.

On to Full Production and Corrective Actions

The appropriate corrective actions should be taken by the contract manufacturer if issues are found during the first article inspection of a circuit board. Those processes will be modified if the problem is due to a manufacturing process.

These adjustments could include changing test documentation, even the build, and the events sequence; solder process profile, or the tools or materials used. However, the customer will be notified with a request for design changes if the problem lies in the design. Wrong PCB footprints or incorrect hole sizes are included in these. Usually, as per the report of documented corrective action, these changes can be made by the manufacturer but only with your permission.

Working with a Manufacturer Having Experience in Builds of First Article

Under the stress of a very compressed design schedule, getting a PCBA China ready, tested, and built for the market is often done these days. This can result in some errors. Working with a contract manufacturer that is well acquainted with these potential issues and has the capabilities, skills, as well as experience to conduct a thorough first article inspection is the key. This way, you will stay assured that your circuit board’s regular production runs will be 100% accurate.