Sourcing a PCB Manufacturer? You Got to Go Through This

Keywords: Flexible PCB, Rigid Flex PCB

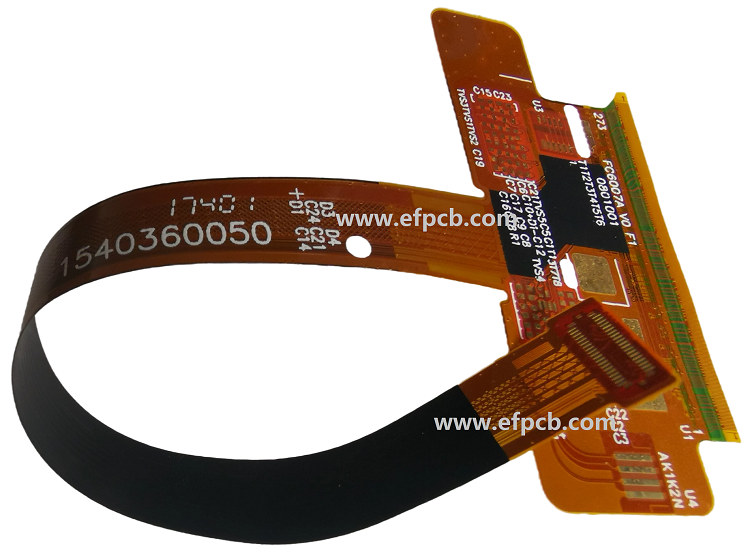

Electronic parts are mechanically supported by a Flexible PCB that is electrically connected with the help of traces etched from copper sheets and conductive pathways. Onto a non-conductive substrate, the sheets are laminated. PCB quality control and design needs are set by standards much of the electronic industry's assembly, which are set by the IPC organization. Regardless of the material used to manufacture the board, IPC-2221A is the main generic standard for a printed circuit design.

Consisting of numerous or one layer of material glued into a single entity, Circuit boards consist of an insulator. Grounding to the board is served by the additional layers. Either by stripping away the excess and coating the entire board in copper or by mechanically laying down individual lines, the copper traces are created. The needed printed circuits are left by stripping away the excess, which connects electronic parts.

With the design process, many printed circuit board shops can help and high-end features such as an auto-router and trace optimizer are offered by this which can reduce the layout time drastically. However, efficient results is achieved for laying out by manual routing. In several ways, a custom PCB can be made. To be very flexible, flex circuit boards are designed for instance. This facilitates them to be used in wire systems and their placement in positions that are otherwise not possible.

In many electronic devices, a printed circuit board is a basic part. From the simple to detailed units, the board's design can vary to match the intended use. However, for ensuring that a high-quality board lasts for the long-term is made, it is essential to find reliable manufacturers.

Factors associated with Flexible PCB

Here are certain essential factors to consider regarding this aspect:

Latest technologies

The latest technologies that can work with modern devices are used by reliable manufacturers. Continuing to use old or obsolete software, there are still many manufacturers. But if creating a high-end product, isn't likely to give the desired results.

Options of Flexible design

In the process of creating the printed circuit board, the capacity to offer customization is certain to be a very appealing quality. At creating the bespoke service to match the specific needs, any manufacturer that can help in this area will be very efficient.

Services offered

Between the existences of different manufacturers, the services types offered are likely to differ. However, the capacity of fixing faults is a beneficial service to be included. So, they can be repaired in an efficient and fast manner if faults are detected in the boards after delivery.

Check reputation

Checking the reputation of the different manufacturers is one of the most basic steps to adopt for shortlisting the best options. By sourcing personal referrals and checking online testimonials or reviews simply, this is achieved. For producing high-quality products, any company with a strong reputation is certain to have the know-how and skill about circuits like Rigid Flex PCB.

Production time

Using a manufacturer offering timely delivery is very crucial. Penalties, Lost orders, or other issues can result from any lags or delays in the build process. The finances can be affected by this. Before committing, you must ensure to check the typical delivery time.

Prototype options

Finding a manufacturer is a further useful point that has an in-development department. This enables the creation of initial prototypes. The option of using the various types of boards, such as the flexible, anti-vibration, and solid is also available with them. For creating the bespoke design, the flexible boards make it a lot easier. When it is essential to have complete control over the shape or thickness of the electronic devices, they are a practical option for instance.

Five usual Errors that occur during the use of Flexible PCB Technology

Underestimating what is involved in having a successful start-up program is the biggest issue in using flexible circuits. Flex is often treated by the supply chain teams like a commodity, giving the process little attention and time. The result is delayed product introduction, higher start-up costs, and poor quality usually.

When starting up a project using flexible circuitry, the following are five usual errors that companies often make.

Believe that no Limitations are present in Flex: In applications of dynamic flex exceeding millions of cycles, Flexible Circuits are operated. This sometimes makes one assume that the manufactured circuit can’t be destroyed. However, premature failure is caused by other elements such as twisting, sharp bend radius, and mechanical abrasion. Regarding any long-term limitations for an application, a knowledgeable supplier can make you aware.

Not allowing the involvement of the supplier in the process of designing: in manufacturing a flex circuit, there are a lot of nuances; the fact that for a design that a hardboard does not face, flexible adds challenges. A product that is more cost-effective, easier to build, and more reliable ultimately is designed by your supplier. A less reliable product, poor on-time delivery, and more quality issues are resulted from forcing your supplier to build to print.

In the matter of supplier selection, they don’t do due diligence: to pick from, there are many flexible PCB suppliers. Each has unique problems and capabilities. It is a recipe for disappointment to base your choice solely on price and assume that your demands can be met by any supplier adequately.

Compressed Timelines: in the electronic package, flex is the last element to be designed often. They are already behind schedule when the product team finally gets around to addressing the flex circuit. This time, shortcuts can be forced by pressure. A poorly designed product having much reliability and manufacturing issues for the product duration is the result. For quick turn production, you will be forced to pay a premium additionally.

Using PCB CAD software to design a flex: This issue is related to the non-involvement of the suppliers, but quality design and common manufacturing issues are not avoided in PCB software. These issues are found in a flexible circuit only. Some of the issues that are not addressed by standard PCB design software are not accommodating material stability issues; solder fillets near bend points, and sharp corners.

For electronic packaging, interconnection is indicated by Flexible PCB Circuits. These are often the most cost-effective. From design, weight, and durability features, they offer a host of advantages. In assuring a successful product start-up, avoiding the above mistakes can go a long way.