Some Facts about the Durability and Reliability in Soft Gold PCBs

Keywords: Soft Gold PCB

In the ever-evolving landscape of electronics, the reliability and durability of printed circuit boards (PCBs) play a pivotal role in determining the success of electronic devices. Among the various types of surface finishes used in PCB manufacturing, Soft Gold has emerged as a reliable and durable choice, especially in applications where both performance and aesthetics are crucial. In this blog, we delve into the fascinating realm of Soft Gold PCB, exploring the reasons behind their rising popularity and the key attributes that contribute to their reliability and durability.

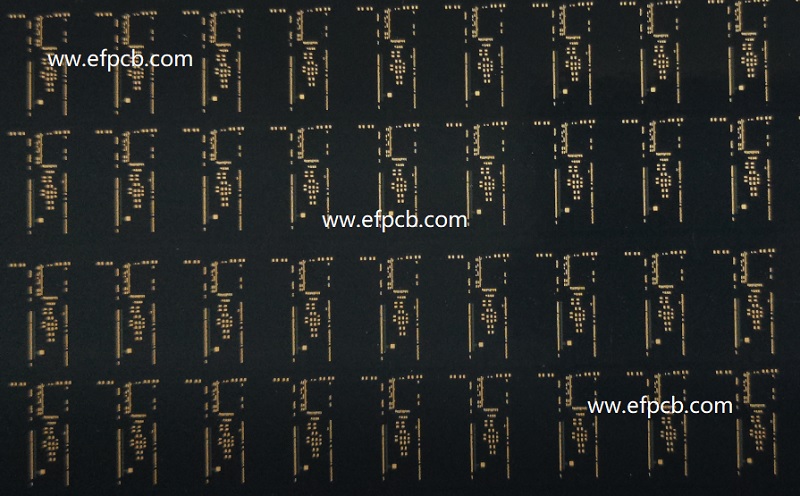

Soft Gold PCBs

Soft Gold, a thin layer of gold alloyed with a small percentage of other metals like cobalt or nickel, serves as a surface finish for PCBs. The term "soft" distinguishes it from the hard gold finish, where the gold layer is thicker and more suitable for applications requiring high wear resistance. Soft Gold PCBs strike a balance between cost, performance, and appearance, making them an ideal choice for a variety of electronic devices.

Corrosion Resistance: A Shield against the Elements

One of the standout features of Soft Gold PCBs is their exceptional resistance to corrosion. Gold, being a noble metal, does not corrode or tarnish easily, even when exposed to harsh environmental conditions. This corrosion resistance is vital for electronic devices that may be subjected to moisture, humidity, or other corrosive elements during their operational lifespan.

Soft Gold's ability to resist corrosion ensures that the electrical conductivity of the PCB remains consistent over time. This is particularly crucial in applications where reliability is paramount, such as medical devices, aerospace equipment, and industrial machinery.

Exceptional Electrical Conductivity: Uninterrupted Signal Transmission

Soft Gold's excellent electrical conductivity is another factor that contributes to the reliability of PCBs. Gold is an excellent conductor of electricity, and when used as a surface finish, it ensures low contact resistance and stable electrical performance. This is particularly important in high-frequency applications, where signal integrity is critical.

The consistent electrical conductivity of Soft Gold PCBs enhances the reliability of electronic devices by minimizing the risk of signal loss, interference, or degradation. This makes them suitable for a wide range of applications, including telecommunications, data storage, and high-performance computing.

Solderability: Facilitating Seamless Assembly

Soft Gold's solderability is a key factor in the manufacturing process of PCBs. Soldering is the process of joining electronic components to the PCB, and the solderability of the surface finish plays a crucial role in the quality of these connections.

Soft Gold's compatibility with various soldering methods, including traditional wave soldering and more advanced techniques like reflow soldering, makes it an excellent choice for PCB assembly. The soft nature of the gold layer allows for a reliable bond between the components and the PCB, ensuring robust connections that withstand the rigors of everyday use.

Wear Resistance: Durable beyond Expectations

While Soft Gold is not as wear-resistant as hard gold, it still exhibits a commendable level of durability. In many applications, the wear resistance of Soft Gold is more than sufficient to withstand the typical stresses encountered during the life of electronic devices.

The durability of Soft Gold PCBs makes them suitable for consumer electronics, where devices may be subject to frequent handling, plugging, and unplugging. Additionally, the wear resistance contributes to the longevity of the PCB, ensuring a more extended lifespan for the overall electronic system.

Aesthetics and Environmental Friendliness: Form Meets Function

Beyond their technical attributes, Soft Gold PCBs also cater to the aesthetic and environmental considerations of modern electronics. The thin layer of gold imparts a sleek and visually appealing finish to the PCB, making it an attractive choice for devices where aesthetics matter.

Furthermore, gold is a recyclable material, aligning with the growing emphasis on sustainability in electronics manufacturing. Choosing Soft Gold PCBs not only ensures reliable performance but also reflects a commitment to environmentally responsible practices.

Miniaturization and High-Density Applications

The trend toward smaller and more compact electronic devices has been relentless, driven by the demand for portability and efficiency. Soft Gold PCBs are adapting to this trend by accommodating high-density interconnects and miniaturized components. Manufacturers are exploring ways to further reduce the footprint of Soft Gold PCBs without compromising their reliability, opening new possibilities for applications such as wearables, IoT devices, and medical implants.

Advanced Materials and Alloys

In the pursuit of improved performance, researchers are investigating alternative materials and alloys to enhance the properties of Soft Gold. These endeavors aim to strike a balance between maintaining the advantageous characteristics of gold—such as corrosion resistance and electrical conductivity—while addressing any limitations. The development of innovative gold alloys or combinations with other materials may pave the way for Soft Gold PCBs with even greater durability and reliability.

Flexible and Stretchable PCBs

As flexible and stretchable electronics gain traction, Soft Gold PCBs are adapting to meet the demands of these unconventional form factors. The inherent flexibility of Soft Gold can be leveraged to create PCBs that can bend or stretch without sacrificing their electrical performance. This opens up possibilities for applications in wearable electronics, foldable devices, and other innovative form factors that were once considered challenging for traditional rigid PCBs.

Smart Manufacturing and Quality Assurance

The ongoing digital transformation of manufacturing processes, often referred to as Industry 4.0, is influencing the production of Soft Gold PCBs. Smart manufacturing techniques, such as the integration of sensors and real-time monitoring, enable more precise control over the manufacturing process. This results in improved quality assurance, ensuring that each Soft Gold PCB meets the highest standards of reliability and durability.

Conclusion

In the realm of printed circuit boards, Soft Gold has carved a niche for itself by combining reliability, durability, and aesthetic appeal. The corrosion resistance, exceptional electrical conductivity, solderability, wears resistance, and environmental friendliness of Soft Gold PCB makes them a versatile choice for a wide range of applications. As electronic devices continue to advance in complexity and functionality, the importance of reliable and durable PCBs cannot be overstated. Soft Gold, with its unique combination of properties, stands as a testament to the ongoing pursuit of excellence in electronic manufacturing, providing a foundation for the creation of cutting-edge and dependable technologies. Whether in aerospace, medical, telecommunications, or consumer electronics, Soft Gold PCBs exemplify the convergence of form and function in the dynamic world of electronics.