Solve the Dilemma of Type of PCB Substrate

Keywords: PCB Substrates, PCB Substrates China

Which PCB substrate is suitable for your next printed circuit board project? One of the first choices made throughout the PCB design process is frequently the IC Substrates, which form the foundation of a printed circuit board.

The PCB substrate not only acts as a basis for the component pieces that are adhered to its surface but also provides a lattice for connections that electrical impulses can follow. Functionality and cost are the two main factors in choosing the material. It should come as no surprise that due to its effectiveness and affordability, the vast majority of consumer electronics use the same PCB substrate.

A PCB substrate

The substance that supports the traces and parts that form the structure of a printed circuit board is known as a PCB substrate. The result and success of a high-quality PCB project depend greatly on the choice of the substrate material.

It has frequently been said that making PCB substrates is like making a sandwich. The strata are often denoted as follows:

The printed circuit board's core, a hard foundation material that acts as its principal insulating layer and is often wrapped with copper foil as an internal ground plane, is located in the middle of the board.

Prepreg, a dielectric material binding agent that coats the core, is used to cover it.

The surface is covered with an outer layer of foil, creating the region where component components will be joined and traces will be etched.

Finally, the solder mask is put on the board's surface. This is done largely to avoid solder bridges, shield the copper traces from oxidation, and aid in visual inspections.

Although believed to be a layer of their own, silkscreen is used to identify which pieces are located where on a board and offers no practical advantage.

Prepreg and core material are typically referred to when we talk about the PCB substrate. The possibilities that substrates provide can be tailored to the needs of the end user.

When and how are PCB substrates made?

As was already discussed, during production, PCB substrates are arranged by layers. These can be layered in multi-layer PCB layouts or be as basic as one-sided PCBs. Metal foil and dielectric material are alternated in these layers.

Thanks to improved electrical performance brought on by lower dielectric constants and loss tangents compared to other materials, the bulk of PCB substrate materials are blended with epoxy. Due to growing environmental concerns about lead-based printed circuit boards, resin chemistry has developed throughout time to accommodate the higher temperatures of lead-free soldering.

As we examine the different IC Substrates China materials employed in the production of printed circuit boards, it's critical to keep in mind that as performance increases, so do costs. When compared to a phone that could be thrown out in a few years, printed circuit boards used in telecommunications, military gear, and aerospace engineering need to operate at significantly higher rates. Therefore, when reviewing the list, place the end-use before the optimum performance.

PCB substrates types

FR-4

The great majority of printed circuit boards on the market are made of FR-4 material. This is intentional because FR-4 boards, which are constructed of woven glass reinforced by epoxy resin, are inexpensive, effective, lightweight, and have exceptional moisture resistance.

Although FR-4 is excellent for consumer electronics, it is not appropriate for high-speed or high-frequency applications because of its significant dielectric loss. Printed circuit board designers choose FR-4 to get excellent outcomes at a low cost when money is the deciding issue.

Flex PCB Materials

One of the most significant advancements in consumer electronics is wearable technology. It demonstrates how far we have gone in the past ten years and how much further we still have to go by combining the usability and functionality of smart devices with the ease of fitting around a wrist. Without flexible printed circuit boards, these gadgets would not be conceivable.

Numerous uses for flexible printed circuit boards exist outside of clothing. Flex PCBs can fit a significant amount of surface area into small or oddly shaped places due to their ability to bend. They may now be found in anything from calculators and video gaming consoles to satellites and medical equipment. They can even operate in hazardous environments.

Flex PCB substrates' greatest strength is their flexibility. As a result, they are made of soft materials and are often produced with epoxy that is curved like a glass weave. Some typical substrates are:

PFC - Polytetrafluoroethylene PTFE, also referred to by its brand name Teflon, is the preferred choice for flex PCB materials. They are used in telemetry, antennas, power amplifiers, and cruise control because of their low dissipation and strong temperature stability.

Polyimide - Polyimide possesses strong conductivity qualities as well as a wide operating temperature range and great chemical resistance. Small consumer items like calculators, cameras, and gaming gadgets are well suited for this material.

PEEK is unrivaled for use in the most difficult circumstances. It has a high melting point, excellent chemical resistance, and can withstand significant radiation exposure. This printed circuit board substrate’s characteristics allow for its application in both aircraft and medical equipment like gamma and X-ray machines.

Substrates for Rigid PCBs

Rigid printed circuit boards cannot be moved, as opposed to flexible printed circuit boards. They become less corrosion-resistant, waterproof, and shockproof as a result. Nevertheless, inflexible PCBS are resilient, economical, and strong despite these drawbacks.

Substrates with a ceramic basis typically make up rigid printed circuit boards. These boards operate at high temperatures and have strong thermal conductivity. They are the simplest sorts of boards to fix and are small, which allows them to occupy less space than some of their competitors.

The three most common ceramic-based materials for printed circuit boards are:

Aluminum is the most often used material for ceramic printed circuit boards because it has a high thermal dielectric and little expansion. It offers exceptional high-frequency performance in even the hardest high-temperature situations and can function up to 350 C before melting. These printed circuit boards' thermal conductivity, however, falls short of what high-power components like integrated circuits require. It is typically utilized in sensors, LEDs, medical circuits, and heating and cooling.

Aluminum Nitride - Aluminum nitride substrates are used in printed circuit boards for high-power devices like LEDs, integrated circuits, and sensors. The heat conductivity of aluminum nitride IC Substrates is over 10 times greater than that of aluminum printed circuit boards.

The prospective uses of beryllium oxide are considerably more advanced since it has an even better heat conductivity than aluminum nitride. Its severe toxicity during the machining process is one issue, though. High-voltage integrated circuits and commercial microwave ovens both make use of it.

For the most sophisticated applications, such as laser fields, there are further materials, like silicon carbide, that has strength at temperatures as high as 1400°C. However, while having a material composition that is the same as a diamond, it is still beyond most buyers' pricing range.

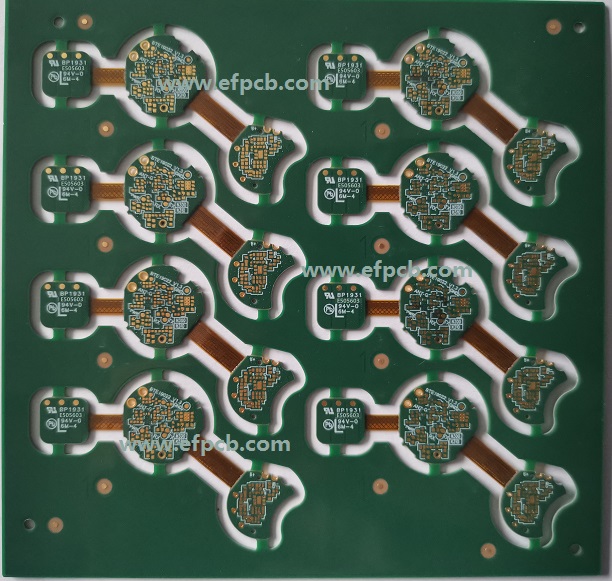

Substrates for Flex-Rigid PCBs

Both types of materials are combined in flex-rigid printed circuit boards, which are typically utilized in aerospace, medical, and military applications. Due to their ease of fabrication and low dielectric loss at microwave frequencies, they generally use polytetrafluoroethylene components like RO3000 and RO4000.