Soft Gold PCB: The Key to High Reliability and Excellent Conductivity

Keywords: Soft Gold PCB

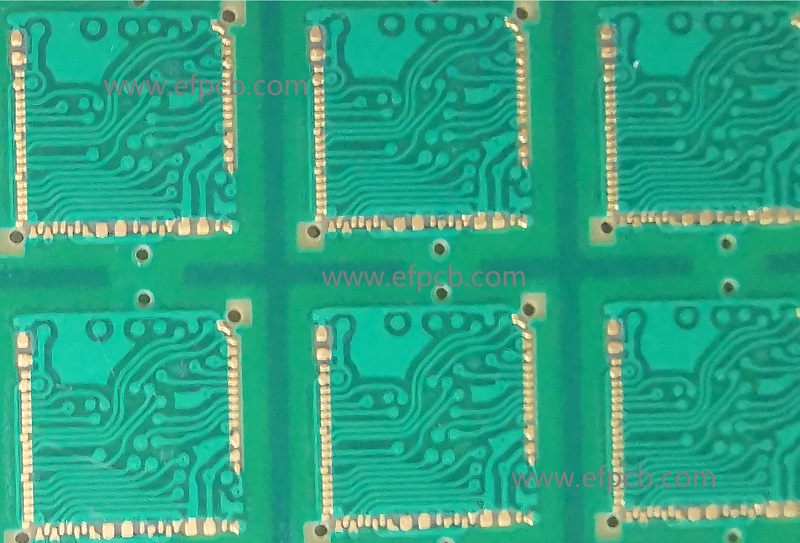

Soft Gold PCB is printed circuit boards that have a layer of soft gold on their surface. This gold layer is applied to the copper traces of the PCB to improve conductivity and prevent corrosion.

Soft Gold PCBs are commonly used in high-end electronics such as aerospace and medical devices. These devices require high reliability and long-term performance, and Soft Gold PCBs offer both.

How are Soft Gold PCBs made?

Soft Gold PCBs are made by depositing a layer of soft gold on the copper traces of the PCB. The process involves several steps, including:

- Surface preparation: The copper traces are cleaned and prepared for the gold plating process.

- Activation: A layer of the activator is applied to the copper traces to promote adhesion.

- Gold plating: The PCB is submerged in a bath of soft gold plating solution. A small electrical current is passed through the solution, causing the gold ions to be attracted to the copper traces.

- Post-treatment: After the gold plating process, the PCB is rinsed with water and dried. The gold layer is then annealed to improve its hardness and durability.

Advantages of Soft Gold PCBs

- High reliability: Soft Gold PCBs are highly reliable and can withstand harsh environmental conditions. They are resistant to wear and tear, making them ideal for use in aerospace, medical, and other high-end applications.

- Excellent conductivity: Soft Gold PCBs offer excellent conductivity, which is essential for high-speed and high-frequency applications.

- Corrosion resistance: Soft Gold PCBs are highly resistant to corrosion, which ensures long-term performance and reliability.

- Easy to solder: Soft Gold PCBs are easy to solder, making them ideal for use in automated assembly processes.

- Aesthetically pleasing: The soft gold layer on the PCB gives it an aesthetically pleasing look, which is essential for high-end electronics.

Conclusion

Soft Gold PCB is a popular choice in the electronics industry due to its high reliability, excellent conductivity, and corrosion resistance. They are commonly used in aerospace, medical, and other high-end applications where long-term performance is essential. The soft gold layer on the PCBs makes them highly resistant to wear and tear, ensuring long-term performance and reliability.