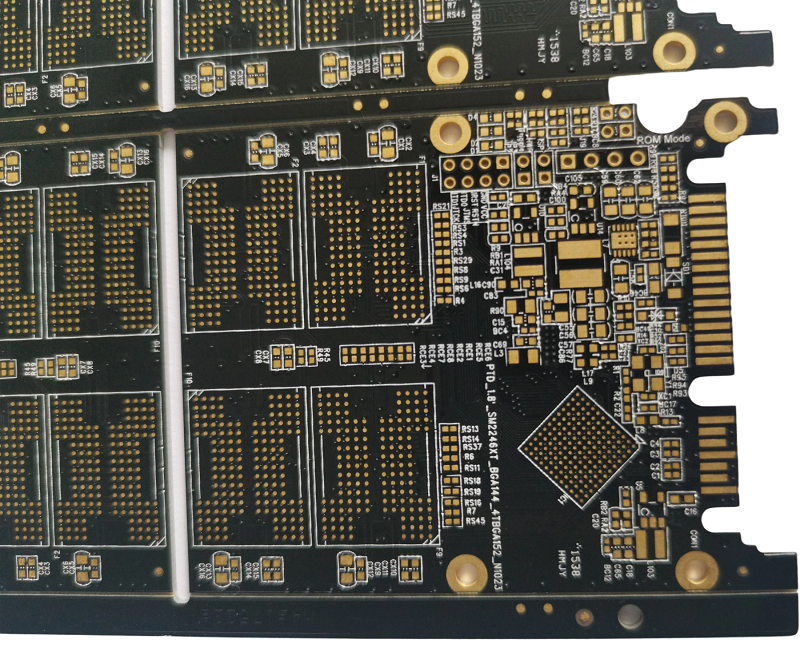

Sloping and Plan Details of PCB Gold Fingers

Keywords: Gold Finger PCB, Plating Gold PCB

To empower associations between different sheets, the gold-plated slender connectors are Gold Finger PCB found on the edge of printed circuit sheets. They work for quite a while with prevalent conductivity and the hardest type of gold accessible; they are produced using tissue gold. Going from 3 to 50 microns, the thickness of gold fingers ordinarily.

As it has the most noteworthy electrical conductivity and consumption obstruction after Silver and Copper, Gold is picked for these fingers. To expand the obstruction of the fingers to wearing and tearing, Gold is joined with Cobalt and Nickel some of the time. From one another on various occasions, PCBs are detached or associated. So some mileage are dealt with by these association focuses.

Making this surface completion, the immaculateness is 99.9% unadulterated gold for all gold applications for PCBs. Applied to printed circuit sheets, there are a ton of sorts of gold completes some remain part of the completed gathering. To safeguard the electro less nickel plating and hidden finish for the gathering system, SMT gadgets and through-openings are utilized.

What is PCB Gold Finger Sloping?

Before the surface completion and after the bind cover testimony, the PCB Gold Fingers plating process begins. The accompanying advances are incorporated:

• Slanting: To make more straightforward inclusion to the relating opening, the edges are then tightened or inclined at a specific point

• Gold Plating: Over the Nickel layer, between 1 to 2 microns of hard Gold is plated in this step. To support the surface opposition, Cobalt is additionally added to Gold in everyday practice.

• Nickel Plating: to the connector edges of the fingers, between 2 to 6 microns of Nickel are plated at first.

PCB Gold Fingers Plan Particulars:

• Counting the plated through openings (PTH) inside 1 mm of Gold Fingers isn't prudent.

• To forestall openness at the hour of inclining the internal PCB layers towards the PCB edges should be sans copper.

• Broke down and feeble PCB board can be the aftereffect of any split the difference with the standard separating values.

• Between the board frame and the gold fingers, keep up with something like 0.5 mm of distance.

• Confronting outwards from the PCB's middle, The Plating Gold PCB ought to be put.

• Close to the Gold Fingers, No screen printing or bind veil ought to be performed.

Non-uniform Gold Fingers PCBs:

The gold fingers are planned to be more limited than others for some PCBs. the one utilized for memory card perusers is the most pertinent illustration of such PCB. To those associated with the more limited fingers, the gadget connected with long fingers should be fueled first.

PCBs with Divided Gold Fingers

Inside similar fingers of similar PCB, some of them are likewise disconnected and portioned gold fingers change long. For tough gadgets and water-safe, Such PCBs are reasonable.

PCB Gold Fingers Quality Measures:

A few principles for the creation of PCB Gold Fingers are recommended by the Affiliation Interfacing Gadgets Businesses (IPC). The IPC guidelines are as per the following:

Substance arrangement: the gold plating ought to comprise of between 5 to 10% Cobalt to accomplish greatest inflexibility along the edges of PCB Gold Fingers.

Thickness: In the scope of 2 to 50 miniature inches, the plating thickness ought to be kept up with. The standard thicknesses by size are 0.125 inches, 0.062 inches, 0.031 inches, and 0.093 inches.

Visual test: Through an amplifying focal point, a visual examination is performed. The contact edges ought to be liberated from overabundance plating like Nickel, have a perfect surface, and furthermore smooth.

Tape test: To actually look at the adhesiveness of the gold plating alongside the contacts, is directed. Over the contact edges followed by eliminating something similar, a portion of tape is secured in this test. For hints of plating, the tape is reviewed in the subsequent stage. On the off chance that any gold is noticeable on the tape, for consistent infusion and launch the plating is thought of as inadequate.

ENIG

Delicate gold is the most famous surface completion utilized by planners. It is fairly effectively overseen and self-restricting, Handled at 1-3 miniature inches is made due. At the point when applied which facilitates handling difficulties in get together, electroless nickel submersion gold (ENIG) as a surface completion is very level.

As of late, we have seen plan engineers increment their solicitations to add more gold remembering that gold is a byproduct. 4-8 miniature inches, for instance, changed standard handling during creation, added lead time, and adding this much gold requires added cost. While these extraordinary orders are handled, this restricts the item that can move. Anyway, for what reason should how much gold be expanded? For adjust handling the additional gold might aid the safeguarding, it must be thought that the regions required.

ENEPIG

Like ENIG, just add palladium is added to the compound simply by electroless nickel electroless palladium drenching gold (ENEPIG). It had its issues when ENIG was first presented. Two to specify are dark cushion and non-wetting. To assist with wetting and security, it was felt that adding palladium to basic nickel would restrict the issue.

True to form, The ENEPIG finish didn't take off. With soured assembling, the planners and purchasers, and a different handling line as well as it added cost for the extravagant palladium coupled. Contingent upon the volume, costs were expanded by 35-60% and this finish expanded handling times. Lead times are stretched out alongside added cost. Commonly it possibly runs when the line will be full or one time per month albeit the cycle is fit as a fiddle.

For timeframe of realistic usability and wire holding, this finish has a few advantages however it includes some major disadvantages.

Gold Fingers

Various utilizations of purpose are available by Gold contacts. Some are connected to an association of some motherboard or sort and for an edge card association. A drenching surface might be available in a card embedded or left for the life span of its life cycle though a card ought to have a hard, gold-plated surface that is eliminated and embedded more than once.

Frequently in mix with a film switch, a PCB is utilized where numerous incitation powers of a keypad are endured by the hidden gold. By the specialist at 200-300 miniature inches, the gold plating on tabs of a keypad is typically characterized. Numerous activation inclusions or powers are made due by hard gold.

Consider your adding machine or console to more readily figure out the life span. Up to long use should be held by every downturn to connect. By utilizing an electrical charge, this kind of gold plating is electrolytic plated or electroplated instead of a simply compound response. By changing the plating process duration, Thickness of Gold Finger PCB might be controlled.