Significant Fields of Utilizations of Flex PCB

Keywords: Rigid Flex PCB, Rigid Flexible PCB Manufacturer

By and large, the commonness of adaptable printed circuit board innovation has seen an impressive flood lately because of its advantages in the developing fields of individual clinical hardware, mind boggling as well as High-Thickness Interconnect (HDI) gadgets, and wearable gadgets. With regards to patterns in the PCB business, Organizations guarantee to remain on the ball and the data they need to do the equivalent is delivered for their clients. This article will offer an immense information on PCB Get together and Rigid Flex PCB Creation.

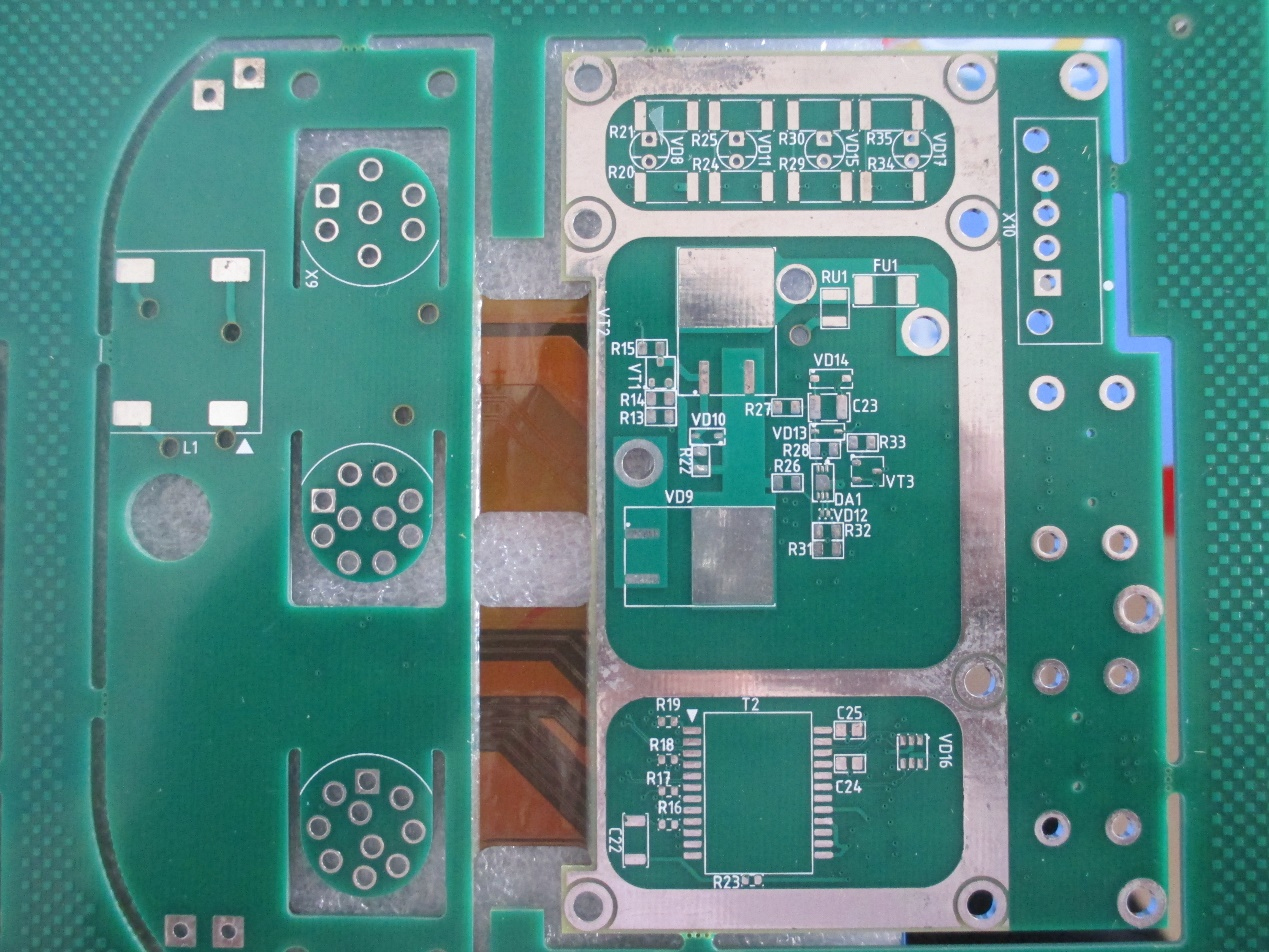

In the first place, to cover the fundamentals: an Unbending Flex PCB portrays other standard PCB Overlay Material or a standard inflexible leading group of FR-4. To an adaptable and flimsy PCB of R-F775 material, it is connected during the PCB Gathering Interaction. To associate the primary unbending PCB to other inflexible little girl sheets, this adaptable piece can be utilized during the PCB Gathering Cycle. It additionally associates with another gadget altogether to fulfill shape or space imperatives, or now and again after creation just

A designed plan of parts and printed circuits that utilize adaptable base material without or with an adaptable cover layer is FPC or Flex PCB. Without harming the wire, it can endure a great many unique twisting, and be collapsed, wound, and bowed uninhibitedly.

Making it conceivable to extend or move in three-layered space and fit the ideal material shape, Flex PCB offers opportunity of plan. More modest space and Lighter weight are presented by the high electrical association and minimal nature thickness of Flex PCB contrasted with the conventional unbending PCB. Its advantages can be informed as follows:

• Lightweight and Little size

• Effectively adaptable and Bendable

• High unwavering quality

• The high thickness of the circuit

Utilizations of Flex PCB

In high-accuracy electronic items, for example, military and aviation, Flex PCB was at first utilized when originally created during the 1960s. It started to be applied in nonmilitary personnel items after the finish of the Virus War. Driven by the advancement of Flex PCB innovation, the utilization of Flex PCB has been completely extended entering the 21st 100 years. The pattern of eventual outcomes' slimness and softness has likewise extended.

The requirement for Flex PCB has hugely developed as the gadgets items get more prominent usefulness while coming lighter and more modest sizes. The Flex PCB characteristics meet the pattern of compact, scaled down, and multifunctional gadgets. Along these lines, it is generally utilized in buyer hardware, fringe items, PC clinical gear, auto gadgets, correspondence items, and so on. The uses of Flex PCB from an Unbending Adaptable PCB Producer in the auto gadgets, wearable gadgets, and cell phones industry are being examined here.

Car Hardware

The standard for the future improvement of the auto business is new energy vehicles. In association with a customary line transporter, auto wiring outfits are muddled and weighty generally. For new energy vehicles, this can't conform to the ceaselessly expanding amounts of electronic parts. Be that as it may, while having the option to endure a great many powerful twisting without harming the wire, Flex PCB offers opportunity of planning. For wire outfits, it makes an optimal substitution. For auto electronic parts, Flex PCB has strength, heat opposition, and high-dependability qualities appropriate in cruel conditions. For gearboxes, Drove vehicle lights, theater setups, BMS, sensors, route, vehicle show, and other vehicle gadgets, it is presently utilized in the new energy vehicles.

The capability of car gadgets has become progressively clear with the proceeded with improvement and development of sensor innovation. The stimulus for the Flex PCB market is supposed to turn into a significant development.

Clinical Wearable Gadgets

To gather all assortments of physiological information for individual wellbeing and determination use, Clinical wearable gadgets are utilized. They should be unpretentious and open to connecting straightforwardly to individuals, which requires a conservative bundle and exceptionally thick designs of the items. Because of its high circuit thickness and adaptability qualities, Flex PCB empowers numerous clinical gadgets are empowered to become lighter, more astute, and more modest. Subsequently wearable observing gadgets, hearing-help gadgets, wristwatches, and so on, are utilized generally.

The capability of wearable electronic gadgets has been featured in the Coronavirus pandemic has featured in medical services. They empower nonstop observing of physiological signs. In the early location of pre-suggestive and asymptomatic instances of Coronavirus, they can be utilized. The interest for Flex PCB keeps on developing with such gadgets expanding in intricacy yet decreasing.

Cell phones

OLED show

As a component of the sign association, Flex PCB is predominantly utilized for pivot, turning, and collapsing parts in cell phones. The OLED show is one of the commonplace applications. The OLED show is another age of show screens and is alluded to as Natural Light Transmitting Diode. Adaptable screens are bendable, lighter, and more slender. They are wealthy in colors and of low influence utilization as contrasted and conventional presentation screens. In new-age electronic items like wearable gadgets, foldable telephones, and bended showcases, are utilized generally. For electronic items involving adaptable screens for their bendable, slim, and light attributes, Flex PCB is more reasonable.

Multi-elements of cell phones

Cell phone brands proceed to improve and develop item works to animate buyers' buy readiness and hold onto piece of the pie bringing about a more popularity for PCBs particularly flex PCBs. For batteries, LCD modules, LCD boards, buttons, and camera modules in cell phones, Flex PCB is utilized from the outset. New uses of face acknowledgment and unique finger impression modules are brought by the presentation of biometrics innovation followed by other imaginative capabilities and numerous cameras. Accordingly, to help the rising highlights in volumetrically restricted spaces, more hardware parts are required which drives unbending PCB to be supplanted by Flex PCB.

The Flex PCB use increments as cell phones keep on developing with further developed highlights. For instance, the utilizations of the recieving wire, power string, spotlight, speaker, vibrator, camera, side button, motherboard, 3D Detecting, HOME button, contact and show module, free backdrop illumination, SIM card holder, earphone, and mouthpiece jack have been shrouded by Flex PCB in the iPhone series.

End

A critical pattern of future gadgets is scaling down. Hardware become lighter, more slender, and more modest for their flexing property with the assistance of Flex PCB. With the rising interest for auto hardware, wearable gadgets, and shopper gadgets, the development of Flex PCB has principally been driven. A higher prerequisite on Unbending Flex PCB innovation and quality is being forced by the quick improvement of such hardware.