Significance and Introduction of Flexible Printed Circuit Board

Keywords: Flexible PCB, Flex Circuits Board

Into a more sophisticated circuit board, The PCBs have evolved over years that you see today. With the ones available in modern smartphones and LED designs, you can compare the circuit boards installed in 1990s TVs.

Into different types including double layer, single layer, rigid, flexible, multiple layers, and rigid-flex aluminium circuit boards, The PCB boards are categorized. Flex Circuits Board are only covered in this article.

a very wide variety of constructions have been created by the combination of today's flex circuit and rigid-flex PCB technology that can add a significant amount of overall packaging reduction, design integration, and functionality to a design. To create an almost endless number of rigid-flex and flex circuit board configurations, most of the specific constructions that we have reviewed in this technical article can also be together combined.

Flexible Circuits Future

Manufactured with substantially higher flex layer counts, there are many new designs. Those with buried and blind via structures, designs with components, and even integrated ZIF connections mounted into both the flexible areas and in some more prevalent designs, the rigid sections are included.

Requiring shielding for Radio Frequency (RF) or Electromagnetic Interference (EMI) considerations, some rigid-flex printed circuit board (PCB) designs may have flex areas. Designs having varying thicknesses are also there between the asymmetrical constructions as well as different rigid areas.

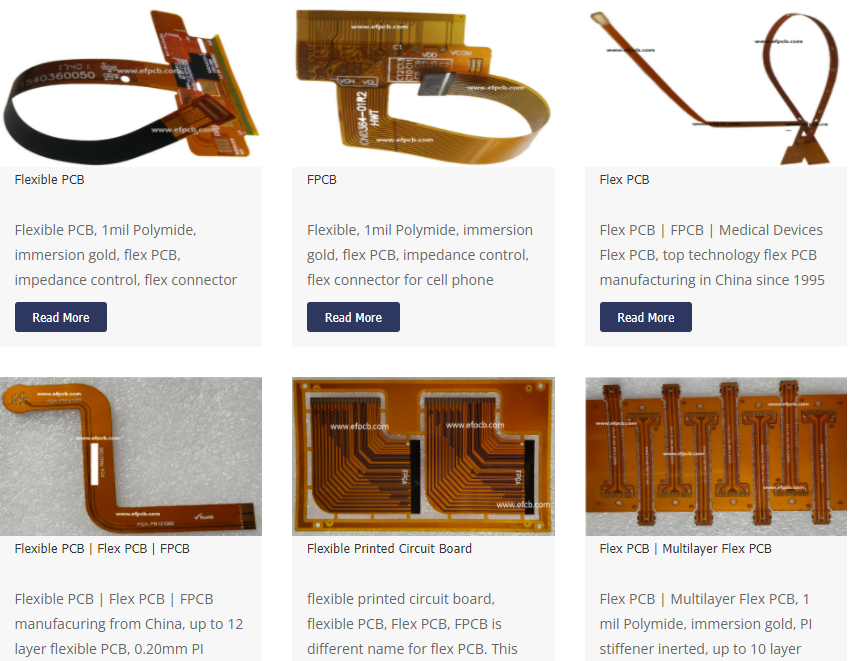

Flex Circuits Board

Special types of circuit board that can be bent into the desired shape are Flexible PCB or flex circuits or flex prints. For high-temperature and high-density applications, they are used widely. Polyimide or a transparent polyester film is present in the flex designs as a substrate material. Making it a right fit for solder mounting components, this comes with high heat resistance.

With a conductive layer of traces, a flexible circuit comes. Combined with a polyimide dielectric layer, it is made up of copper. From 0.0001’’ to 0.010’’, the copper conductive layer thickness can vary and from 0.0005’’ to 0.010’’, the dielectric material thickness can range. To bond the conductive copper layer to the substrate, an adhesive is needed while sometimes to attach the copper with the substrate, vapour deposition is handy equally.

On many factors, the selection of material for making flexible circuit boards is a somewhat tricky. It includes mechanical and chemical resistance, types of flexing, temperature, current, and capacitance.

As they come with fewer interconnections, the flexible designs are more reliable. Thus, fewer contact crimps and solder joints are ensured. And less space is needed by these circuits due to their flexible capability of bending. As compared to rigid circuit boards, only 10% of the area is covered by them.

Flex Circuits Board Manufacturing Process:

To manufacture flexible PCBs, Polyimide is used as a base substrate material. As compared to FR-4, this material is more expensive. Thus, you must use it cautiously. To keep circuit boards close to each other, the nesting technique is used to appropriately use the polyimide material.

Manufacturing Flex Circuits Board

Steps for manufacturing flexible boards are:

Looping

The circuit assembly and servicing length is ensured by the service loop. The extra material amount added beyond the limit of the designer is this.

Sizing Conductor

As a conductive material on the board, thin copper is used. For the flexibility of the circuit, the thin copper is responsible. For dynamic applications, it makes it suitable.

Etching

To compensate for any isotropic losses, the etching process is used during the process of manufacturing. In this process, the line width loss is double the thickness of copper foil. The different types of conductor, etch mask and Conductor used are included in the factors influencing the line width.

Routing

Routing is very easy. Bending as well as folding is improved and stress is reduced by Routing.

Ground Planes

The weight of the board is reduced by creating ground planes and better circuit flexibility is promoted.

Next before applying filleting, you need to create holes where the pad area is increased to divide stress. Then for dynamic flex circuit applications, add adhesive-backed films. Next before adding film polymers photo imaginable liquid, you need to apply screen-printable liquid overcoats that act as a solder mask. You can prevent the circuits from both external as well internal damages.

Flexible PCBs Types

Into different four types, Flexible printed circuit boards are divided.

HDI Flexible PCB

For high-density interconnect, The HDI stands. These circuit designs come with better layout, construction, and design as well as are efficient and reliable as compared to other boards. Better electrical performance is offered by reduced package size and HDI flexible boards. This is because for the manufacturing of these boards, the thinner substrate material used.

Double Flexible PCB Layer

A conductive layer on both sides of the PCB is offered by the double-layer flexible PCB. On either side of the conductive layer, this allows you to connect electrical components.

Single Flexible PCB Layer

As the name suggests, only one conductive layer that sits on the flexible dielectric film is present in the single-layer flexible PCB. On only one side of the PCB, The electric components rest.

Rigid-Flex PCB

A combination of both flexible and rigid circuit boards is the rigid-flex PCB. Higher component density is offered as compared to other circuit boards.

Multiple Flexible PCB Layers

With three or more conductive layers, the multi-layer flexible PCB comes. By a dielectric material, these layers are separated. High board flexibility is ensured by the irregular lamination and in the bonding area, lamination thickness is normally less.

Modern World Significance

Into any shape, the flexible boards can be bent. For dynamic static and flexing applications, they are used widely. Regular flexing makes up the dynamic circuit boards while for static applications, the circuit boards used offer minimum flexing.

To withstand high temperatures between -200° C and 400° C, Flexible circuit designs are made. In the oil and gas industry, they are a right fit for borehole measurements are used for this due to this reason.

In many applications, Flexible boards come in handy but as a replacement for rigid circuit boards, you cannot use them. In high-volume automated fabricating applications, rigid boards can be installed and they are cheap.

For applications requiring regular flexing, high accuracy, better performance, and precision, the flexible circuit board is a right match. Flexible circuit boards applications include:

- Antilock brakes

- Cameras

- Ultrasound probes

- Fuel pumps

- Medical devices

- Semiconductor test

- Satellites

- Motion systems

- Bar code equipment

- Battery packs

- Avionics

- Airbag systems

- Manufacturing devices