Server PCB: Vital Elements, Choosing a Server PCB Manufacturer And Future Development

Keywords: server PCB

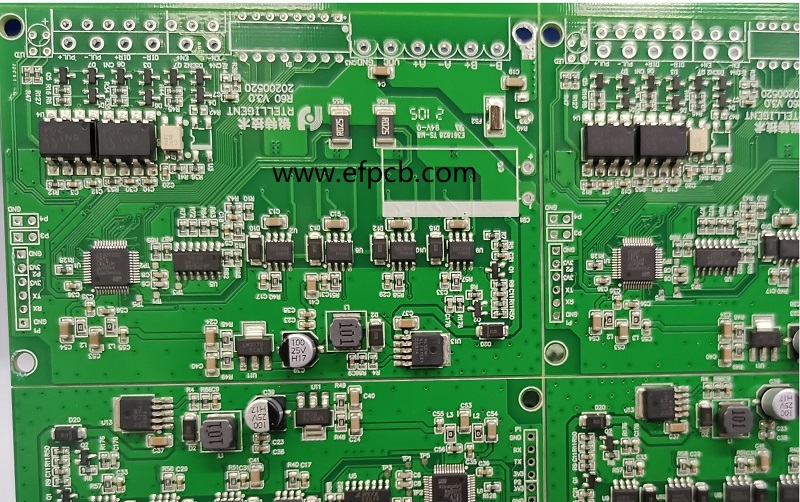

The term Server PCB often refers to the Printed Circuit Board used in servers or server-related gear. Servers are the computers or devices that offer the services or access to some of the resources or capabilities that other machines in a network, referred to as clients, need. The PCB in a server is a critical assembly that interconnects and interrelates varying aspects of the system like the CPU, RAM, storage devices and network connections.

Here are the following important aspects of a server circuit board:

High-Density Design: Server PCBs are often designs densely because it is required to accommodate many numbers of CPUs, modules of memory, expansion slots and other such things. This should entail reliable signaling and information transfer between such parts.

·Specialized Features: A-server PCBs may have many power connectors and its components may have duplicate for fail over, plus intricate ventilation systems to augment the dependability and availability of the server.

·Multi-Layer Design: A significant number of server PCBs incorporate numerous signal and power planes, as aforesaid. This design is very important in neat handling and control of power supply, distribution and keeping off electromagnetic interferences or EMI in high end servers.

·Customization: Server PCBs mostly run customized to the type of server hardware present in the server room. They have to come in various form factors and that may include ATX, EATX and even proprietary form factors.

·Data Center Optimization: Thus, Server PCBs are rather an essential in data center operations. This pertains to controlling power usage, cooling, and the flexibility of a server to add more resources as dictated by the workload in the anticipated load.

·Reliability and Redundancy: Due to the critical roles that servers play in today’s systems, servers are usually designed to be very reliable. To avoid theuality of having to replace the server PCB, it is common to have the gadget possessing features of twin power supply, ECC memory support, & error-correcting inbuilt in its design.

·Compatibility: Another requirement to the PCB design is that it should be compatible with a wide range of HW parts so that if something goes wrong with a server, one only has to replace some parts with others.

In conclusion, it can be said that the matters of design as well as the characteristics of the server PCB count a lot on how the server would perform, how reliable the server would be and how scalable the server layout is. It is essential in ordinary data centres and other IT parts of large companies to satisfy client needs for computing and networking.

How to Choose the Best Server PCB Manufacturer?

Selecting the right server PCB manufacturer is an important step to ensure that the quality, reliability and performance of the server hardware is up to the mark. undefined

Experience and Reputation

Select reliable manufacturers who have dealt with quality server PCBs in the past. Look at their duration of operation and any recognition they have received in the market. Ask for contacts and testimonials from other customers who have had an experience with their services

Certifications and Quality Standards

Check for certification standards that the manufacturer complies with such as ISO 9001, ISO 14001 or any other assured standards in the production of PCBs. Remember whether they can provide proofs of prior knowledge in attaining the specific quality and reliability measures that are mandatory for server PCBs.

Technical Expertise

Assess the manufacturer’s capabilities for technical processes while creating technologically Advanced server PCBs. It is not rare for servers to need distinct PCB technology attending to the demands of rendering high-level computation.

Customization

Analyse whether the manufacturer is ready to accommodate your specific server design and provide you with corresponding PCB services. Servers are also categorized based on the form factor and may need to be physically altered.

Quality Control and Testing

Ask about the requirement of quality control and check if they conduct tests before making their products. They should go through firm tests in order to find out how reliable those server PCBs are, particularly for the highly availability systems.

Production Capacity

Find out if the company will be able to provide all your needs in manufacturing volume. Hypertext servers are often made in hundreds, thus the maker should in a position to meet your requirements.

Supply and Lead Time

The following things should be understood by the by the buyer regarding a manufacturer’s supply chain capacity and time: Delivery of the components and PCBs should be done on time so that there is continuous production of servers.

Costs & Pricing

Nevertheless, price is an extremely important component, yet it cannot be a main criterion in choosing a car. Different manufacturers also have different levels of quality and reliability in making server PCBs, therefore, any decision based purely on cost savings is likely to bring problems in the future.

Location and logistics

As is evident, assess where the manufacturer is situated in relation to shipment and transport. This will improve on some key factors such as cost of transportation and time of delivery because the plants or centres are likely to be close.

Communication and support

Evaluate the abilities of the manufacturer that provides communication with customers and helping them. Constant communication with a manufacturer is vital as they can address or adjust the required PCB in a snap due to their excellent customer support.

Environmental Responsibility

This could connect with your business’s values and its commitment to becoming more sustainable and responsible regarding the environment, or not, given the manufacturer's focus on this subject.

NDAs and IP Protection

Ensure that the manufacturer is ready to accept NDAs and has robust IP protection measures into consideration for your innovations.

It is crucial to research extensively, at least attend the company that you have been sourcing from is willing to show you their manufacturing facilities, and ensure that you have clear communication regarding your needs. When selecting a manufacturer to engage, one should ensure that he or she engages a reputable and competent manufacturer who will deliver the best and quality server hardware.

What are the positive and negative trends in the development of server PCB?

Some of the technical and industry attributes present today are likely to define the further evolution of server PCBs in the following ways. While it is difficult to foresee the future with confidence, some probable paths for the development of server PCBs include:While it is difficult to foresee the future with confidence, some probable paths for the development of server PCBs include:

High-Performance Computing (HPC)

The use of server PCBs will help meet the increasing procession requirement. This includes designing and incorporating the PCBs with high-speed data buses, sever PCIe lanes, and/or signal integrity.

Increased integration

The page also confirms the trend of introducing more components into a single PCB will persist. This will likely require integrating more power management, enhanced cooling mechanisms, and possibly graphic processing units directly on the server printed circuit boards.

Advanced Materials

While the servers become more energetic, capable of generating heat, it is important to stay on the modern materials for PCBs with optimized heat dissipation properties.

Energy efficiency

Energy efficiency and power optimization will once again remain on focus. Server PCBs should have an efficient design since they power many data centers and consume a considerable amount of energy.

High-Density Interconnects

With system components, such as servers, getting smaller and packing more tightly within shipping containers advanced connection solutions will be deployed to maximize data transfer rate without suffering from interference crosstalk.

Signal and Power Integrity

Fundamentally, always remember that signal and power integrity are your topmost concerns. They have also emphasized the superior design for EMI/EMC and signal quality as the key to success.

Advanced Cooling Solutions

With enhancing the workloads of servers, the PCB cooling solutions, for that matter, will progress. Redundant cooling, enhanced heat sinks among many others, will be incorporated in the server boards.

Security enhancements

Protection will be added at the field level to the processors of the server to prevent brainstorming and unauthorized access to sensitive data.

Scalability and Flexibility

Since the present generation data center is fluid and dynamic, the server PCB must be capable of accommodating a variety of configurations. This might specify possibilities for adding new components, as well as support for hot-swappable ones.

Edge Computing

As edge computing becomes commonplace, server PCBs could progress to fulfill the needs of distributed and far-off application that may eventually require more compact and hardened PCBs.

Environmental Sustainability

To make a long story short, it comes down to the simple fact that a focus on environmental sustainability can lead to server PCBs that are both: a) less power-hungry, b) longer-lasting.

5G and Edge Technology

Since future computing paradigms such as 5G, edge computing, etc. demand low latency and high bandwidth, Server PCBs also have to deliver the same at par with these technologies. This may need more complex circuit boards a possible reason for the disparity between the two is due to differences in complexity.

Quantum Computing Support

Over time, quantum computing might call for unique server PCBs to ideally reinstate co-processors and interact with devices of a quantum nature.

Conclusion

The development of Server PCBs will be greatly influenced by further technological enhancements in servers, data center structures, and emerging axial shift in computations. It will also be influenced by the pressure for heightened performance, increasing energy efficiency and the ability to answer for fluctuating demand in computers. Hence, to keep pace with these new trends in the data center and server business for the server PCB makers involve the following.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top HDI PCB Manufacturers (2024)

- 6Top 10 Flexible PCB Factories in 2025

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact