Role of part-to-part spacing in PCB Design for Assembly

Keywords: PCBA China, PCBA Assembly China

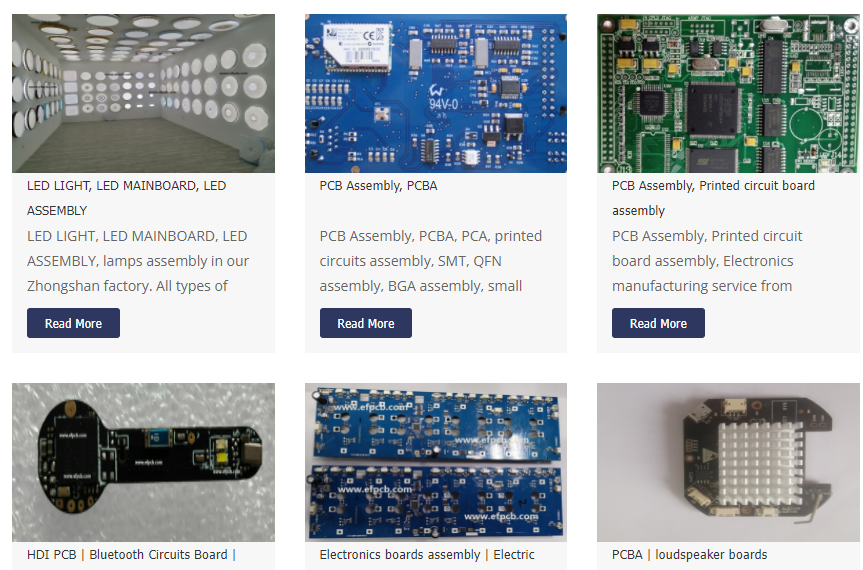

One of the most important and frequently misunderstood elements is designing with PCBA assembly China in mind. This article will help you in becoming someone whose PCB design has been optimized on the first try which then ensures a smooth quick turn PCB production process.

Design for Assembly (DFA)

It is quite simple. In those who are not PCB masters yet the problem that arises is that the initial PCB design does not fully take assembly into account. Instead, their focus is on the board itself that too without knowing the broader context of how the board will be used in the product or application.

Many complications can arise by overlooking PCB assembly. When you view it in isolation the PCB design seems to be perfectly acceptable, but later on, certain design decisions may make assembly difficult.

Then comes the question of component availability. The assembly vendor needs to have the requisite components on hand as soon as the boards arrive so that the PCB assembly process can work smoothly and the PCB production as a whole can progress effectively.

By paying attention to part-to-part spacing, PCBA China masters can avoid making these mistakes.

Component-to-component spacing is one of the frequently asked questions that arise from the designers who are not yet PCB masters. Various issues can get created by placing a component too close to another component which may need redesign and refabrication, which then leads to a loss of time and money.

During assembly to avoid part-to-part spacing issues, PCB masters use different techniques. Their footprint is designed in such a way that there is always enough gap between component boundaries. This gives you a clear picture of any potential issues that may arise from components being too close during placement.

Careful placement of components should be done by designers so the place-bound component shapes do not overlap each other. PCB Masters can disregard the place-bound shape and move components closer to one another if the board does not have enough space along with keeping the minimum spacing rules in mind.

Keep in mind the rules of components, requirements, and proximity regulations that are present in your PCB design software. For various part types, PCBA Assembly China masters have specific component-to-component spacing guidelines.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact