Rigid Flexible PCB Manufacturer and it’s Benefits

Key words: Rigid Flexible PCB Manufacturer, Rigid Flex PCB

New advancements having establishes in the past are once in a while experienced apparently in gadgets. Around back to 50 years, in rocket Rigid Flex PCB advancements follow to the need to supplant wiring tackles. In the primary financially accessible portable PC unbending flex advancements were utilized.

Not many of the applications that depend on satellites, PCs, flex PCBs, clinical gadgets, wearable advances, and test hardware today.

Rigid Flex PCB

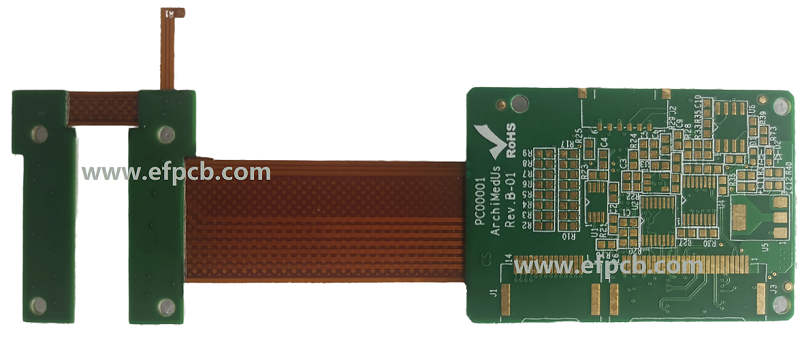

As the name infers, a mix of both unbending and adaptable substrates is a rigid flex PCB. To interface sub circuits on rigid PCBs, at least one adaptable circuits are utilized. With adaptable polyimide material, rigid flex PCBs are normally created on copper cladding substrate. To the unbending FR4 board, they are associated.

A multi-facet worked with cushioned through openings are included by the adaptable piece of the unbending flex PCB getting the interconnectivity between layers. From just utilizing the adaptable substrate to having genuine sub circuits based on the adaptable region itself, unbending flex PCB has developed as a swap for wire outfits.

Rigid Flexible PCB Advantages

When contrasted with ordinary unbending PCB, a rigid flex PCB Planning is extensively really testing. There are a few valid justifications on why in certain plans there is utilization of unbending flex and that to in which that includes fitting the board in restricted spaces.

• Space Saving

Frequently, space is an extravagance in the plans that require an unbending flex PCB. For instance, from an unbending flex PCB plan, handheld warm scanners can benefit as there isn't a lot of room to fit in high profile connectors and wire bridles. All things being equal, you'll have more space to course the follows around with the interconnecting circuit worked in on the adaptable substrate.

• Greater Dependability

At the point when there's a need to eliminate the wire tackle from the PCB regularly, Connectors fill their need. The gamble of disappointment is expanded by adding connectors to the PCB for a plan including numerous interlinking sub circuits in a nook. The requirement for board-to-board connectors is taken out by executing a rigid flex plan. In some cases inclined to disappointment, this likewise prompts lesser bind joints.

• Testing Simplicity

As the whole sub circuits are as of now interconnected, it is likewise simple to computerize testing of an unbending flex PCB when the PCB is produced. Before the parts are collected, the capacity to dispose of network issues further to forestall superfluous costs and wastage.

• Less Expense

When contrasted with their rigid partners, unbending flex PCBs from Rigid Adaptable PCB Maker are less expensive by and large as the previous is harder to deliver. Notwithstanding, the general expense of the item is decreased by utilizing unbending flex PCBs. You'll save money on the expense of gathering as the conductive layers of adaptable material replaces wired interconnects, which includes physical work now and again. In the nook it is mounted on, there isn't a requirement for introducing a wire tackle as an unbending flex PCB is a finished circuit all alone. For every unit of the item, such a wiring position is an extra expense and occupies valuable time.

Rigid Flexible PCB Configuration Difficulties

The adaptability and flexibility is off-set by different difficulties permitting you to fabricate three-layered items and plans. For your item to the truly more grounded unbending piece of the gathering, you mount the skeleton, connectors, and parts by the assistance of conventional rigid flex PCB plans. Once more, the adaptable circuit just filled in as an interconnector with regards to conventional plans, while working on the protection from vibration and bringing down the mass.

New plan rules for rigid flex PCBs have been presented by new item plans combined with further developed flex circuit advancements. The opportunity to put parts on the adaptable circuit region is currently present with your plan group. You and your group are empowered to incorporate more hardware into the plan by joining this opportunity with a multi-facet way to deal with unbending flex plan. Nonetheless, a couple of difficulties are added in acquiring this opportunity concerning openings and directing.

For PCB planners talented in unbending flex plan, there is a squeezing interest as a period of scaling down is being observers by the items. Understanding that planning a rigid flex PCB requires different ranges of abilities is fundamental before you take on the test.

In a 3-layered climate, you'll have to begin imagining the plan As opposed to adopting an unadulterated electrical strategy. Into a nook, a rigid flex configuration is generally fitted and you should think about the mechanical components.

Somewhat, the adaptable piece of the PCB is in some cases bowed. This implies in the mechanical weight on the material, you'll have to gauge. To forestall untimely disappointment, the curve region or twist line should be painstakingly managed.

As the paddings are debilitated by the mechanical pressure, cushions and vias should be kept away from in the curve regions. To the twisting line, Follows ought to likewise be steered oppositely for primary strength. To reinforce the twist region, you can add sham follows alongside the current follows.

The flex region ought to have an incubated polygon for the ground plane rather than strong copper planes. Assuming you're utilizing OrCAD PCB Architect, this can be effortlessly finished. For rigid flex plan, the creator should be streamlined.

Configuration Impacted by Electromechanical Variables

Think as far as electromechanical variables influencing both the rigid board and the flex circuit when you plan unbending flex PCBs. Center around the proportion of curve span to thickness as you construct your plan. The opportunities for disappointment are expanded by an expanded thickness or tight curves at the twist region with flex circuits. Keeping the curve span at least multiple times the flex-circuit material thickness is recommended by the fabricators.

Compacting it along the internal twist or extending the flex circuit along its external curve should be stayed away from. Pressure at one point and extending at one more point on the flex circuit is expanded by expanding the curve point past 90°.

The guide type and thickness found in the twist district is one more central point of contention in unbending flex unwavering quality. By utilizing cushions just plating and lessening how much plating on the guides, you can diminish mechanical pressure and thickness. The utilization of weighty nickel, gold, or copper plating permits mechanical cracking and stress to happen and diminishes adaptability at the curve.

Collaboration Required by Rigid Flexible PCB Plan

The capacity to recreate the activity of flex circuits, envision 3D electromechanical plans, deal with numerous layer stacks, and check configuration rules is given by new PCB configuration devices to your plan group. On collaboration between your fabricators and group, the effective plan of an unbending flex PCB depends even with these devices close by.

At the earliest phases of the Rigid Flexible PCB project, Collaboration should go on all through the plan pivots and interaction on reliable correspondence in the wake of starting.