Rigid-Flex PCB Offers Numerous Benefits

Keywords: Rigid Flex PCB, Rigid Flexible PCB Manufacturer

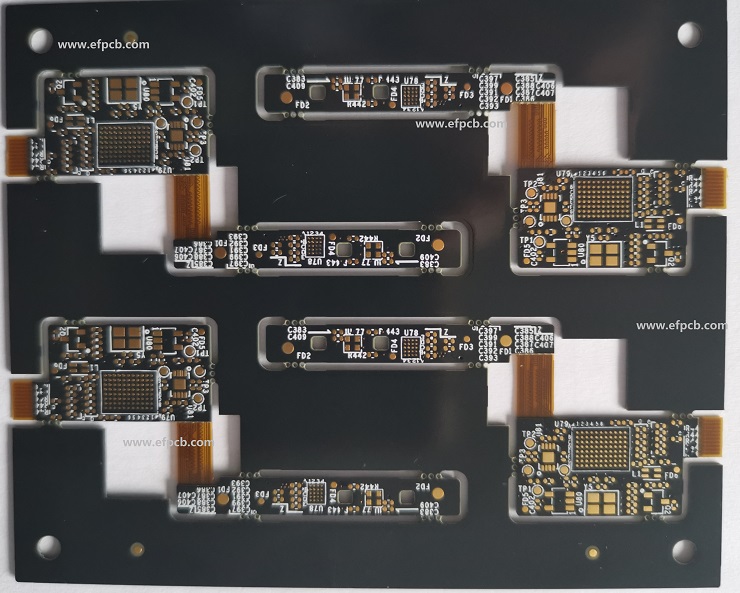

A Rigid Flex PCB combines rigid and flexible substrates, as the name suggests. It is usually made from flexible polyimide over a copper cladding substrate and rigid-flex PCBs link to rigid FR4 boards. Typically, the flexible portion of a rigid-flex PCB has many layers cushioned through holes to ensure interconnection. In rigid-flex PCBs, genuine subcircuits are now created on the flexible region itself, rather than just using the flexible substrate to replace wire harnesses.

Benefits of a Rigid-Flex PCB

Designing a rigid-flex PCB is far more difficult than designing a traditional rigid PCB. Rigid-flex, however, is employed in some designs for excellent reasons, notably when fitting the board into small places.

Boost your reliability

When the wire harness needs to be frequently removed from the PCB, connectors are useful. Adding connection to the PCB can only raise the chance of failure for a design that has several interconnected subcircuits in an enclosure. Fewer solder connections are used in rigid-flex designs, and these solder junctions can occasionally fail.

Saves space

A rigid-flex PCB from Rigid Flexible PCB Manufacturer is frequently required in designs when space is at a premium. For instance, since there isn't much room for high-profile connections and wire harnesses, rigid-flex PCB designs are advantageous for portable thermal scanners. Instead, you will have more room to route the traces because the linking circuit is already incorporated into the flexible substrate.

Cut costs

Due to the difficulty of manufacturing rigid-flex PCBs, they are often less expensive. However, employing rigid-flex PCBs can make the product less expensive all around. You'll save money on the cost of assembly, which in certain cases requires manual work since wired interconnects are substituted with conductive layers of flexible material. The enclosure it is mounted on doesn't require a wiring harness to be installed.

Testing Simplicity

Since all the subcircuits are already linked when the Rigid Flex PCB is built, automated testing of the PCB is very simple. Eliminating connection problems before the components are put together can also save waste and costs.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact