Rigid Flex PCB and its Utility

Rigid Flex PCB, Rigid Flexible PCB Manufacturer

PCB Board Introduction

In the present electronics world, PCB plays a very important role in functioning of various electronic devices. It provides a constant mechanical support to each electrical component at the same time it also assists electromagnetic shielding, heat transfer and many more. PCB is used to connect the electronic components with the use of conductive path ways and signal traces. It can be single layered i.e one copper layer or double layered i.e two copper layers or multi layered basing on the requirement. Based on another classification, PCBs can be classified into Rigid PCB, Flexible PCB and Rigid Flex PCB.

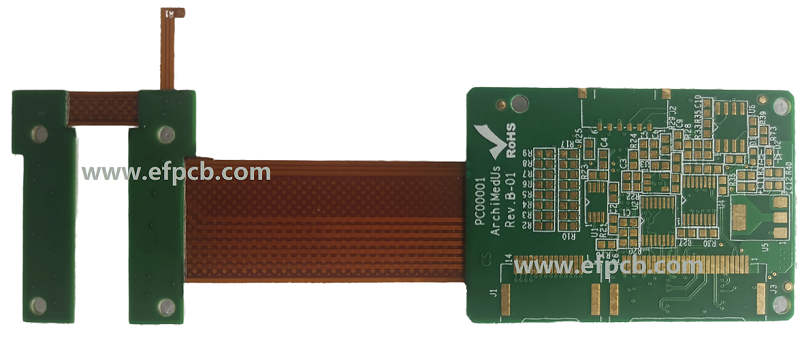

By the nomenclature it is easily understandable that, Rigid PCBs are strong & inflexible, where flex PCBs can be bent or otherwise shaped to fit inside the electronic device. For easy understanding, Rigid Flex PCB can be considered as the hybrid counterpart of both Rigid and flexible PCB. Rigid-Flex PCBs are composed of a combination of both rigid and flexible circuit boards that are mechanically connected to each other.

Rigid Flex PCB Application

For a Rigid Flexible PCB Manufacturer, it is more challenging to manufacture rigid flex PCB because these boards are designed in a three dimension space, which offers greater spatial efficiency for more convenience. Rigid-Flex PCBs provides a wide range of applications, starting from smart devices to cell phones and digital cameras etc. In medical devices such as pacemakers the application of rigid flex PCB technology is pervasive now a days for its space and weight reduction features.

It is always recommendable that before selecting a Rigid Flexible PCB Manufacturer, due market research should be done and a reliable PCB manufacturer or supplier should be chosen for getting the quality PCB for your required electronic device.