Range of Applications for PCBs You Must Know

Keywords: Circuits Board

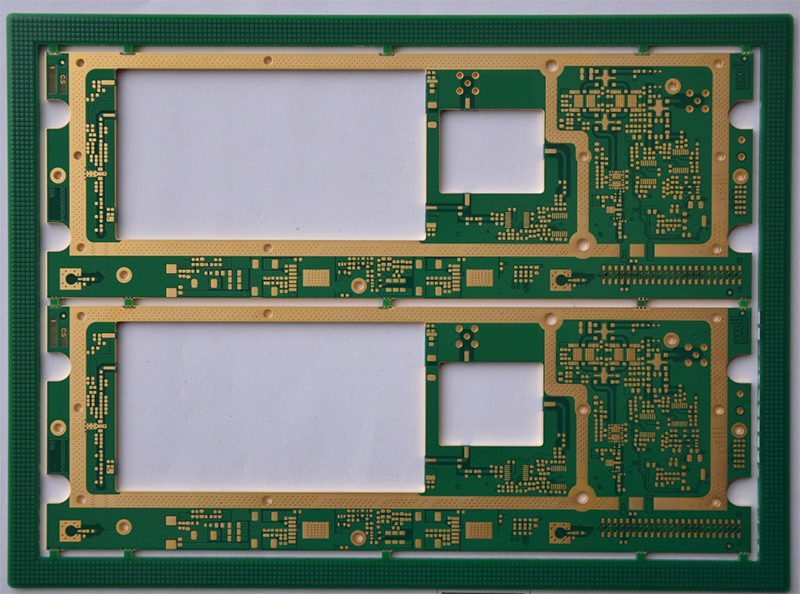

PCBs, or Printed Circuits Board, are very important subassemblies of electronic components. Everyone utilizes them daily and is immensely relevant to numerous fields of work and commercial activity. There is a virtually immeasurable amount of applications for PCBs but we will be looking at ten typical printed circuit board uses.

What does Printed Circuit Board do?

PCBs are prints that interconnect electronic devices. Now, they’re components inherent to the electronics we rely on in our everyday lives in various industries. They are crafted from a material that does not conduct electricity, and the lines, pads and other analogous formations are – etched from copper sheets that interconnect all the electronic constituents of a given product. Some other PCBs may have some other components like capacitors, resistor soldered to the board.

Types of Assembly Processes

Two general approaches to the PCB applications are thru-hole and the surface mount.

Thru-Hole Mounting

In the thru-hole mounting process the assembler involves Graves the component leads into holes drilled on the bare PCB. This technology was the first one used for the manufacturing of the PCBs.

Thru-hole technology can provide a more durable link than surface mount technology can, and that is why it is applied to critical systems. This is so because the leads extend along the entire length of the board unlike in surface mounting where the leads are soldered on. Thru-hole technology is also applied in devices, which are used for testing and, particularly, prototyping because such components are best suited for manual adjustments.

Surface Mounting

Surface mounting is basically the placement of components onto the surface of the PCB using solder. This method was invented in the 1960.Ther though started in the 1980 becoming common from then on. t has become the most popular in use and is referred to as the Component-Mounting Method. In a surface mount board the different layers of the PCB are joined not by thru-hole but by small components called vias.

This method of mounting enables the assembler to mount other components on the other side of the board also. Mounted components can also be small in size therefore more components can be fit in a single board. This cuts down cost and has made it possible for size of electronic devices to continue decreasing year in year out. Another advantage of the surface mounting can also be accomplished in relatively shorter time and is a process which is less complex than thru hole mounting and so it reduces cost.

Where can print boards be found? Below are ten of the most typical uses of PCBs by market:

Medical Devices

Incorporation of growing numbers of PCBs is being utilised in the healthcare sector as the technologies developing new capacities are emerging. PCBs are used in the devices applied to diagnostics, monitoring, handling and others.

Extra care should be taken while manufacturing medical PCBs, because their functions are very sensitive and might be very essential for the patient’s well-being. In some uses PCBs also require specification for cleanliness, particularly those PCBs that are implanted into systems. Implant and many other applications such as emergency room monitors require that boards used be of relatively small size. Because of this many medical PCBs are high density interconnect or HDI Medical PCBs.

Use of PCBs in Medical Devices

Medical imaging systems: Computed tomography, computer aided tomography and ultrasonic scanners usually employ PCBs as do the computers that aggregate and interpret such images.

Monitors: Equipment measuring heartbeat, blood pressure, blood sugar level, obesity and many others employed electronic part to take the reading.

Infusion pumps: IV flow pumps include intravenous infusion pumps for administering insulin, patient-controlled analgesia pumps, and the like that deliver a set volume of a fluid to the patient. These products depend on PCBs in order to operate optimally and with the correct precision.

Internal devices: Internally implantable devices such as pacemakers and other related devices need small PCBs to be used.

Today, the medical industry has continued to hail new ways of employing electronics. As the development of this technology advances and miniaturization and density and reliability of boards become feasible and cost effective the role of PCB in healthcare will continue to grow.

LEDs

LEDs are another widespread type of lamps commonly applied to the residential and commercial illumination and in automobile manufacturing, medicine and computer engineering and many others. They are used because they are energy efficient, last long and are compact in size.

PCB also has a function to help to dissipate heat far from the bulb in utilization LED applications. This paper will show how extreme heat has an adverse effect on the general lifespan of LEDs. That is why PCBs used in LED production are usually made from aluminum – this metal conducts heat well as compared to the other metals. This will reduce the complexity of design, and there is no need to have an additional heat sink any more resulting in arriving at a smaller size in a design.

You can find LED PCBs in:

Residential lighting: Smart bulbs and LED help homeowners to light up their property in the most efficient way possible.

Storefront lighting: Businesses can use LEDs for special notices as well as illumination of their outlets.

Automotive displays: LED PCBs can be used as an element of new dashboard indicators, headlights, brake lights, and much more.

Computer displays: LED PCBs are widely used to provide the power to indicators and displays on laptop and desk top computers.

Medical lighting: LEDs help illuminate an area well and emit less heat, making them suitable for medical uses; including surgical and emergency procedures.

In the future, LED is used commonly in various systems, therefore it is anticipated that PCBs would have increased participation in the lightings.

Consumer Electronics

Some of the electronics used in daily life such as smartphones, computers among many more consumer electronics cannot operate without PCB’s. If we continue to introduce electronic parts into most of the products, PCBs are unavoidable in our existence.

tucked into watches, the wrist, and clothing in general, which are still capable of carrying out numerous complex functions while using small scaled Circuits Board with a high degree of connection density. PCBs required for consumer electronics also have to be fairly inexpensive, so as not to jack up the price of the final product significantly. Manufacturers also need reliable boards, because they require their products to work properly if they are to remain in business.

Communications devices: Many consumer electronics products such as smartphones, tablets, smartwatches, radios and communications products will not be possible without PCBs.

Computers: PCBs are common in both personal and business use of computers.

Entertainment systems: Household equipment including televisions, stereos, video game consoles, electronic amusement and virtual systems all use PCBs.

Home appliances: Almost all the home appliances also contain electronics and PCBs, such as refrigerators, microwave ovens and coffee makers.

Industrial Equipment

The application of PCB in the industrial field is very extensive, ranging from computer products, communication products, automobiles, home appliances, medical equipment, mining machinery and other harsh environment products. Electronic components drive most of the appliances found in manufacturing and distribution processing facilities as well as other types of industries.

Circuits Board used in the industrial sector requires high power in some cases depending on the requirements of the industries it is required in and must be sturdy and capable of withstanding the environment inside the industrial premises. PCBs may require physical endurance for tough handling, intricate machinery vibration or variably, high or low temperatures or chemical sensitive handling.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact