Printed Circuit Board Assembly: Tools and Technology

Keywords: PCBA China, PCBA Assembly China

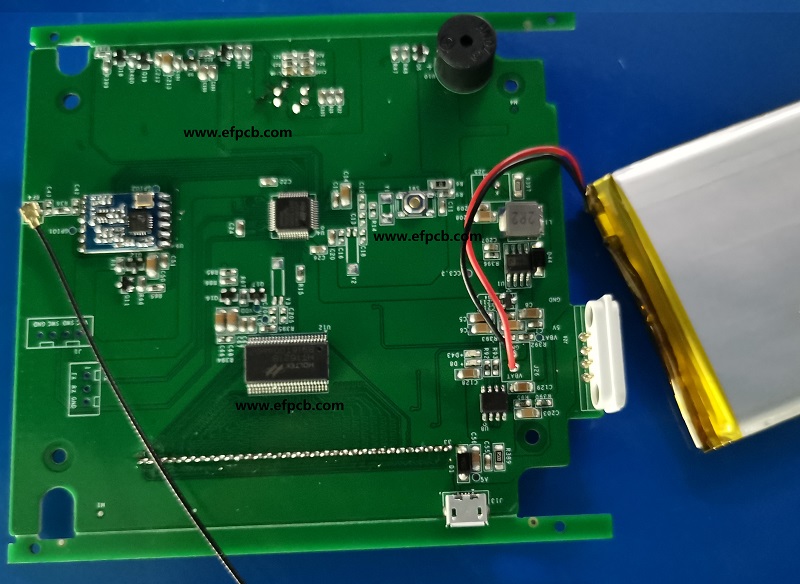

The process of soldering or assembly of electronic components to a PCB or printed circuit board is Printed circuit board assembly, also known as PCBA Assembly China. In this process, Different Automatic and Manual PCB Assembly Tools are used. It has to be noted that from PCB Manufacturing Process, the assembly of a circuit board is different. Various processes including creating PCB prototype and PCB designing is involved in manufacturing printed circuit boards. Before it can be used in any electronic gadget or equipment, Passive and Active Electronic Components need to be soldered onto it once a PCB is ready. The purpose of the circuit board, type of electronic components, and Type of Printed Circuit Board determine this assembly of electronic components.

Things Needed for Printed Circuit Board Assembly

For PCB assembly, the following consumables, electronics parts, and PCB Assembly Tools are needed –

Basic Electronic components

- Printed Circuit Board

- Soldering materials including solder preforms, solder paste, solder wire, solder balls for BGA, and solder bar, based on the soldering type to be done.

- Soldering equipment including testing and inspection equipment, wave soldering machine, soldering station, SMT equipment, etc.

Soldering flux

- It is time to start the printed circuit board assembly process once all of the raw materials, electronic parts, and above equipment are arranged.

- Assembly of Printed Circuit Board with Thru-Hole Electronic Components

- Thru-hole electronic components are electronic components having leads coming out. Through tiny holes, Leads are inserted into the PCB for soldering.

- Hand soldering and Wave soldering are included in the soldering or assembly process for these components.

Wave Soldering –In a high-temperature bath, solder in the form of solder bar is put in a PCBA China process. In molten form and forming, a wave at a very high temperature this solder remains in the bath. On the type of solder, the range of temperature depends. Traditional lead or tin solder, as compared to lead-free solder, has a lower melting point. Over molted solder, the PCB with all the thru-hole electronic components in holes is passed using a conveyor belt.

The following steps are included in the whole Process of wave soldering PCB Assembly:

- Flux application

- Electronic components inserting

- Wave Solder

- Preheat

- Testing

- Cleaning

The PCBA is tested and cleaned once the wave soldering is done. It is sent for rework if any solder joint or fault defects such as Blow Hole or Pin Hole Wave Soldering Defect are found, which is generally done by hand.

In repair and rework jobs or with less workload, Hand Soldering is done in manufacturing units. in the process, A good quality soldering iron, flux, soldering station, and solder wire are used.

Assembly of Printed Circuit Board using Surface Mount Technology (SMT)

For SMD electronic components, Surface Mount Technology or SMT is a PCB assembly process. Legs or leads are absent in SMD components. On the surface of the circuit board, they are mounted. From the thru-hole soldering process, another soldering material, electronic components and the equipment used in this assembly process are different.

PCB Assembly Machines and Tools

From PCB manufacturing equipment, pcb assembly tools and machines for manual repair work and automated printed circuit board assembly process are different.

Those who Design Different Types of PCBs beginning from designing PCB prototypes to manufacturing PCBs from raw PCB material to copper itching and layering are PCB manufacturing equipment.

Used to Assemble Electronic Components to the PCB, PCB Assembly Equipment, Machines, and Tools are those to complete the Printed Circuit Board Assembly. For mass manufacturing, production, or manual small-scale PCB assembly or manufacturing, this assembly process can be automated.

Automated PCB Assembly Machines for Through-Hole Soldering

For Through-Hole Electronic Components, Automatic Soldering Machines are:

Wave Soldering Machine: For any Automatic PCB Assembly Line for Mass Production, this is the main machine. In the following sections, this Huge Machine is again divided into:

- Flux or Fluxer Sprayer

- Conveyor Belt

- Producing Solder Waves with the Help of a Pump, A Pan of Molten Solder.

Preheating or Preheater PAD

Solder Pot: As the wave soldering machine, this machine also works on a similar principle but a very small scale. Dip Soldering can be done in just a Pot with Molten Solder. In the Production of Small PCBs such as LED Bulb or Small Scale Manufacturing, this machine is used generally.

Automated PCB Assembly Machines for SMT

For SMT Production Line, Automatic Soldering Machines are the following:

Curing Oven / SMT Baking Oven: An oven is required for both adhesive curing and operations in electronics. The same or different ovens may be used for solder paste baking and adhesive curing baking of solder paste.

Reflow Soldering Machine: For reflow soldering of SMD with Solder Paste, the Most important machine. Infrared and Vapor Phase is included in two major Reflow Soldering Processes.

Place Machine and SMT Pick: Onto the PCB, Picks, and places SMD electronic components are soldered before SMD soldering.

SMT Pick and Place Process and Machine (Surface Mount Technology)

Solder Paste Printer Machine Screen: For Solder Paste Screen Printing onto the PCB.

Equipment for Solvent Cleaning: To remove excess solder flux, a Machine is used to clean electronic assemblies (PCBs) after soldering.

Inspection Equipment and SMT Repair: For repairing any issue and Inspection the Final PCBA.

Manual PCB Soldering Equipment

Used either for Small Scale Manufacturing, Production, or Repairing, these machines are useful. Major of this Equipment and Tools are:

- Soldering Iron and Station

- Selective Machine for Soldering

- Manual and Automatic Screwdrivers

- Hot Air Blower for SMD

- Magnifying Microscope and Lamp

- Pliers and Cutters

- Soldering Consumables (Solder Flux, Bar, Wired, Paste)

Equipment and Tools for ESD Prevention and Protection

The PCB is first conceptualized in the process of PCB design. For the contacts, Engineers create a blueprint and how the PCB should be layered. Various factors like their orientation, the dimensions of the components, the soldering process, and the type of PCB (double-sided, single-sided, etc.) are accounted for by the design process. Used to design PCBA Assembly China, There are different tools available.