Prevent these Five Major Issues in PCB Manufacturing

Keywords: PCB Manufacturer, PCB Manufacturing

Ensuring the consistency and quality of PCB Manufacturing processes is a crucial concern for manufacturers of printed circuit boards (PCBs). Brand reputation can get damaged, expensive testing cycles and redesign may get kicked off, development can be stalled and warranty claims may increase by The discovery of defects if these issues reach the consumer.

PCB developers seek to avoid these five most common issues of production:

- Tombstone Effect

- BGA Spacing

- Acid Traps

- Test Point Existence

- Visual Features

For manufacturing methods, simulation-driven design is being preferred by the electronics developers. They do this to offer solutions and enhance their efficiency of production. This will make them avoid the most common issues plaguing PCB production.

PCB Manufacturing Tombstone Effect

By improper wetting, Tombstoning is caused. At the ends of the component terminals, an imbalanced torque causes the component to lift from one end when the solder paste starts to melt.

Sources

The difference in soldering time is caused by a difference in connected traces of each pad of a two-pin device during the reflowing process. A tombstone component results from this.

Verification checks

Compare the connected traces ratio: To get a proper connection, one pad could require more heat due to a mismatch in heat-dissipating traces between two pads. Therefore, a wetting force imbalance that causes tombstoning will be generated by the temperature difference. The ratio between the connected copper at the pads is within the allowable ratio must be ensured to prevent tombstoning.

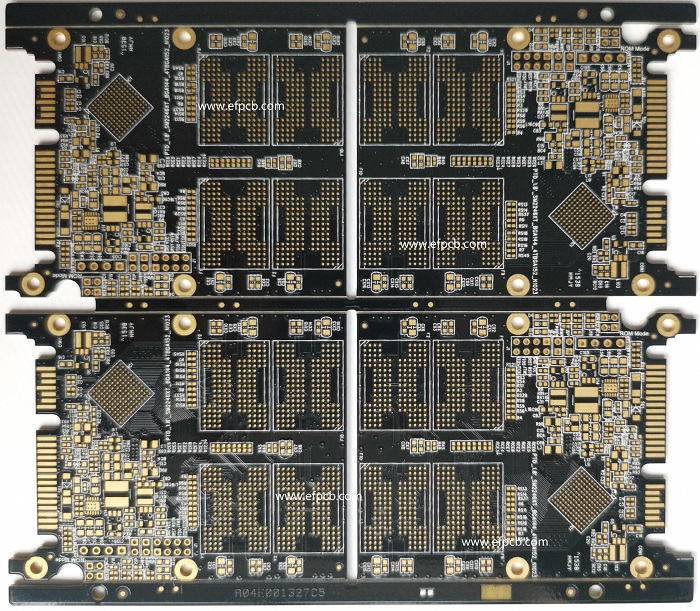

PCB Manufacturing BGA Spacing

To incorporate high-performance ICs into complex and densely populated, PCBs BGA components are a major key. However, to ensure the proper functionality of the BGA chips, there are certain issues that must be considered. In terms of time and resources, fixing some of these issues post-manufacturing could prove costly.

Sources

With pads for the ball grid under the die, the majority of the issues with BGAs are associated.

Proper connectivity of the component is ensured by a proper spacing policy around each BGA pad.

Verification checks

BGA pads Clearance for vias: at the center of four BGA pads, the through-hole vias between the BGA pads need to be present for the best case BGA routing. That invites a chance of solder applied to BGA pads in case this is not achieved to scavenge into the vias as most BGA pads are defined as a non-solder mask.

PCB Manufacturing Acid Traps

Usually sharp corners, Acid traps are pocket spaces on the PCB in which etching solutions could get trapped. To strip excess copper from aboard, these etching solutions are used during manufacture by PCB Manufacturer. There is a risk of it tunneling through the board if they are trapped, leading to faulty traces and causing corrosion to the traces.

Sources

At a sharp angle, Traces connecting to holes without teardrops are usually connected. This results in acid trap creation.

As an acid trap, trace bending below 90 degrees most likely acts during fabrication, specifically when residual acid gets collected in the trap area before washing.

Verification checks

For traces, you must check for sharp corners: patterns that are connected to a pad from a 90-degree angle are looked for in this check, helping the user fix routes that during etching will be problematic. Whether angles are routed in angles other than 45 or 90 degrees can be identified by the user in this check. At all traces flagged, this offers a glimpse as coming into the pad at 90 degrees.

Teardrops Existence: if a component group is lacking a teardrop can be determined by this check, especially where the probability of breakout for vias is possible for DIP type components.

PCB Manufacturing Test Point Existence

Within an electronic circuit, a test point is a location that is used either to inject test signals or monitor the state of the circuitry. It is important to add fixtures, for easy testing of vital components and nets when designing a PCB. To test objects with rework or no modification or minimum to the design, such testing setups are essential.

Sources

Equipment errors may be difficult to diagnose if test points are overlooked In the design stage during verification in the assembly and manufacturing stage.

Verification checks

Check the test points' existence: Typically in the design, test points are incorporated for testing critical components and nets which are associated with those with difficulty to access or power delivery, but some areas may be missed. For specified nets and components, check for the existence of test points.

PCB Manufacturing Visual Features

An important role is played by the overlay layers in the post-manufacturing debug as well as manufacturing process when designing a manufacturable PCB. Information such as component outlines, first pin marks, and reference names are contained in the overlay layers. To avoid any layout discrepancies, making sure information about these overlay layers is accurately represented is important.

Sources

The first pin indicator helps in case of placement as well as debugging for complicated multi-rowed pin ICs.

The reference names also provide details for cross-probing with the schematic for arrays of passive components.

On top of copper areas such as underneath a component or vias and pads, these reference names shouldn’t be placed.

Verification checks

For arrayed passive components, you must check the order of reference names: So that they correlate to the correct component to be placed in the array, Reference name ordering for arrayed components should be accurate.

Check first pin mark existence for complex ICs: errors during the assembly process can be avoided by marking the first pin for complex ICs. This error results in the placing of components in an incorrect orientation.

Reference names overlapping with other objects must be checked: placed on certain objects on the board, Reference name should be avoided to prevent several issues like ink on traces and ink in holes creating PI and SI issues, creating bad solder joints, and ink of solderable surfaces.

Verification Results Sharing

As performing the critical checks themselves, it is vital to distribute the PCB Manufacturing verification tests results effectively.