PCB Prototypes Varieties and When to Use Them

Keywords: PCB Prototype, PCB Prototype China

PCB Prototype must also be at least somewhat functional, but most prototypes are just created to test basic user functions. A design team may utilize several PCBs throughout the life of a project at different phases of the design process. These prototype types include, among others:

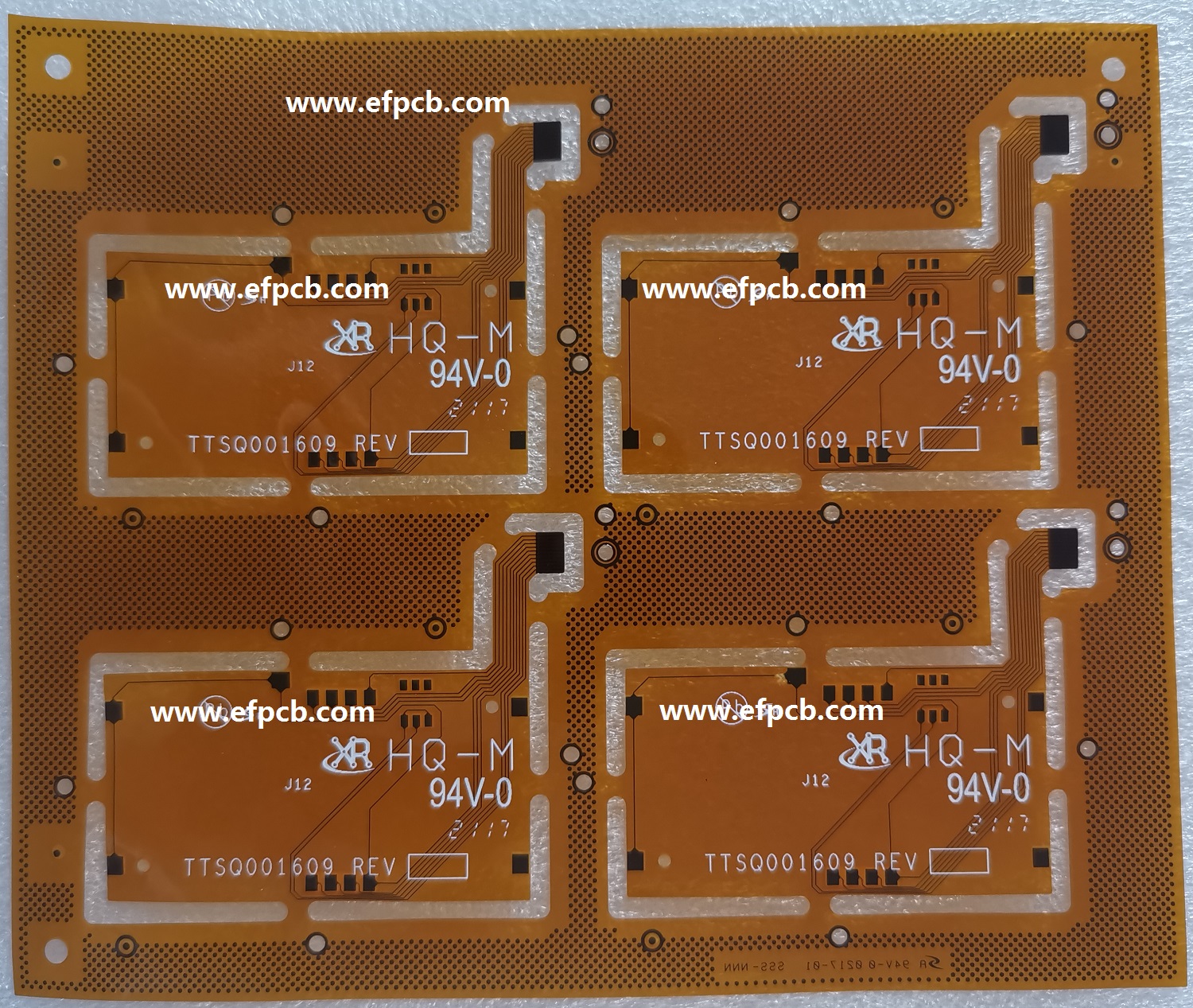

Visual models: Visual models are used to display the overall form and component structure as well as to highlight the physical features of the PCB design.

Working prototypes: These are functional circuit boards that have all of the intended features and capabilities of the finished product.

Functional prototypes: Functional prototypes are intended to be as similar to the final product as possible, giving the most realistic picture of how the design will seem and function. However, to keep the cost of prototyping low, certain fundamental material changes may be included.

Applications of PCB prototypes

Creation of new products: Prototyping will be important if a project calls for a novel design or function. By testing the required function and the design as a whole using prototypes, the design team may identify problems early on in the process. Prototyping is crucial to check the general functioning of your product before moving further with the design phase, even when the project is identical to others your team has worked on in the past.

Testing: PCB Prototype China is required for all testing, including environmental and quality assurance tests. To be ready for proper third-party testing, your team may immediately start conducting tests using prototype PCBs. The more accurate the PCB, the more accurate the tests will be.

Complex elements: Prototyping is going to be the finest choice for projects that are especially complicated and have numerous parts and structures. Breaking down each function using straightforward PCB prototypes can help identify issues early in the design phase. Complex structures are notoriously difficult to change when problems arise. By doing this, your team will spend less effort identifying the problem's root cause and more time enhancing the circuit boards' overall design quality.

Modeling objectives: Sometimes you don't need a working PCB, only a visual depiction of the actual design. In this situation, a PCB Prototype created from inexpensive materials can be a great answer. You may get the visual help in this way without having to pay for a typical production board.