PCB Price Trends: Navigating the Past and Projecting the Future

Keywords: PCB Price

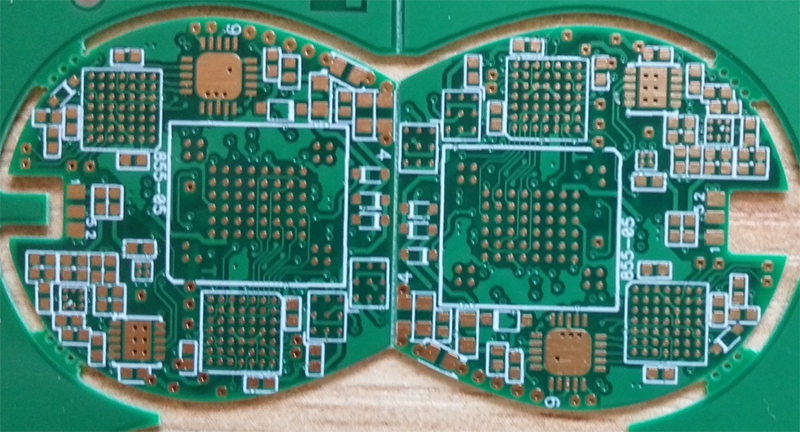

In contemporary electronics, printed circuit boards, or PCBs, are the unsung heroes. They serve as the backbone for nearly all electronic devices, from smartphones and laptops to medical equipment and industrial machinery. Over the years, the PCB manufacturing industry has witnessed significant advancements in technology, materials, and production methods. These innovations have not only improved the performance and functionality of electronic devices but have also influenced the pricing trends of PCBs. In this blog, we will explore the historical and projected trends in PCB Price and how technological advancements have played a pivotal role in shaping these trends.

Historical Trends in PCB Pricing

To understand the present and future trends in PCB pricing, we must first take a step back in time and analyze the historical evolution of the PCB manufacturing industry.

Early Years: PCBs were initially labor-intensive products. The production methods involved hand-drawing circuit diagrams and etching copper boards with chemicals. The manual labor and limited automation made PCBs expensive, especially for low-volume production.

Transition to Mass Production: As electronic devices became more common, the industry witnessed a shift from handcrafted PCBs to mass production. This led to economies of scale, significantly reducing the cost per unit. PCBs became more affordable as a result.

Advancements in Materials: Over the years, advancements in materials have improved the quality and performance of PCBs. For example, the introduction of FR-4, a flame-retardant material, made PCBs more durable and cost-effective.

Miniaturization and Multi-layer PCBs: With the increasing demand for smaller and more complex electronic devices, the industry shifted towards multi-layer PCBs. These high-density boards allowed for more components in a smaller space but came at a higher cost due to increased complexity and manufacturing precision.

Globalization and Competition: The globalization of the electronics industry introduced fierce competition among PCB manufacturers, further driving down prices. Companies across the world began offering cost-effective solutions, benefiting both consumers and businesses.

Technological Advancements: Continuous technological advancements in PCB Design software, manufacturing processes, and automation further reduced costs and improved quality. These innovations paved the way for more efficient production and lower prices.

Projected Trends in PCB Pricing

As we move into the future, several key factors will shape the trends in PCB Price.

Automation and Industry 4.0: The integration of automation and Industry 4.0 principles will continue to drive efficiency and reduce labor costs in PCB manufacturing. This trend is expected to lower production costs and subsequently PCB prices.

Advanced Materials: Ongoing research and development in materials will lead to more innovative and cost-effective solutions. New materials will offer enhanced performance and durability while being more affordable for manufacturers.

Sustainability: With a growing focus on sustainability, there is an increasing emphasis on using eco-friendly materials and practices in PCB manufacturing. While these materials might be costlier initially, the long-term benefits in terms of reduced waste and energy efficiency can have a positive impact on overall costs.

Demand for High-Density Interconnects (HDI): With the proliferation of small, high-performance devices, the demand for HDI PCBs will rise. These complex boards, while more expensive to produce, will be more cost-effective for manufacturers due to their reduced footprint and higher component density.

Geopolitical Factors: Political and trade tensions between countries can affect the supply chain and prices. Manufacturers may diversify their supplier base to mitigate risks, which could influence pricing.

Customization and Prototyping: The demand for customized PCBs and rapid prototyping services is growing. While customization may incur higher upfront costs, the benefits of faster time to market and optimized designs can outweigh the initial expenses.

Impact of Advancements in Technology on PCB Pricing

Advancements in technology have played a pivotal role in shaping the historical and projected trends in PCB pricing. Let's delve deeper into how these technological advancements have impacted PCB costs:

Improved Design Software: Modern PCB design software has become more user-friendly and efficient. It allows engineers to create complex designs with greater ease and precision, reducing design errors and minimizing the need for costly revisions.

3D Printing and Additive Manufacturing: The integration of 3D printing and additive manufacturing techniques in PCB production offers cost-effective solutions for prototyping and small-batch production. This reduces the need for expensive molds and tooling.

Surface Mount Technology (SMT): SMT components are smaller and lighter than their through-hole counterparts, which reduces the size and weight of PCBs. This miniaturization lowers material costs and enables the creation of compact devices.

Automation and Robotics: Automation in PCB manufacturing significantly reduces labor costs, while robotics enhances precision and consistency. These technologies contribute to cost savings in production.

High-Quality Materials: Technological advancements have led to the development of materials with improved electrical, thermal, and mechanical properties. These materials can be more cost-effective due to their enhanced performance, reliability, and durability.

Eco-Friendly Manufacturing Processes: The adoption of eco-friendly practices, such as lead-free soldering and waste reduction, not only aligns with environmental concerns but also lowers manufacturing costs through improved efficiency.

Prototyping and Simulation Tools: The availability of advanced prototyping and simulation tools allows engineers to identify and rectify design issues before production. As a result, there is less material waste and less money spent on production.

Here are a few ways in which technology has empowered smaller entities in the PCB industry:

Online PCB Prototyping Services: Numerous online platforms offer PCB prototyping services, allowing users to upload their designs, choose materials, and receive professionally manufactured PCBs at competitive prices. This has made it feasible for startups and hobbyists to bring their electronic projects to life.

Open-Source Hardware: Open-source hardware platforms like Arduino and Raspberry Pi have gained immense popularity. These platforms provide open access to PCB designs, enabling enthusiasts and small-scale developers to modify and produce their versions of these devices.

3D Printing: The integration of 3D printing with PCB manufacturing enables the creation of custom PCB enclosures and housings, reducing the cost of producing small runs of electronic devices.

Educational Resources: The availability of online tutorials, forums, and educational resources has made PCB design and manufacturing accessible to a broader audience. Individuals and students can learn the skills necessary to create their PCBs, reducing the need for costly outsourcing.

Conclusion

The historical trends in PCB Price reflect the industry's evolution from labor-intensive craftsmanship to highly automated, cost-efficient manufacturing. The projected trends are equally promising, with continued technological advancements expected to drive down costs and improve the quality of PCBs. As the demand for smaller, more complex, and customized electronic devices continues to grow, PCB manufacturers will need to embrace new materials, methods, and practices to remain competitive.

The impact of advancements in technology on PCB pricing cannot be overstated. From improved design software to automation, these advancements have enabled cost-effective, high-performance solutions. The ongoing pursuit of innovation will ensure that PCBs remain an integral component of our technologically advancing world, accessible to a wide range of industries and applications.