PCB Manufacturers and Reasons Electronics Are Taken for Granted

Keywords: Printed Circuit Board, Printed Circuit Board Manufacturer

If you are reading this, there is a good chance that you are utilizing a printed circuit board. However, it's equally true to state that most people are unaware of what they are. A Printed Circuit Board, often known as a PCB, is essentially a thin piece of board made of fiberglass or material comparable to it.

Since then, there have been several changes, and PCBs have advanced significantly. The most widely used example of printed circuit technology, the mobile phone, shows off the largest advancements by making sure they are far smaller than they ever were.

Though less noticeable, more recent changes include a departure from the conventional flat and rigid design and the use of bendy boards made of a variety of flexible materials in certain modern devices.

Printed circuit boards play a prominent part in widely used electronic devices like computers and digital cameras, but they are also present in many other more important and specialized goods like medical equipment and aircraft avionics. Given that the PCBs are essential to the secure and dependable operation of this equipment, the PCB makers must have extremely high requirements. Similar to how power in a home needs circuitry, wiring, fuses, etc. to keep it functioning properly, printed circuit boards hold the instrument's lifeblood inside its circuitry and connectivity.

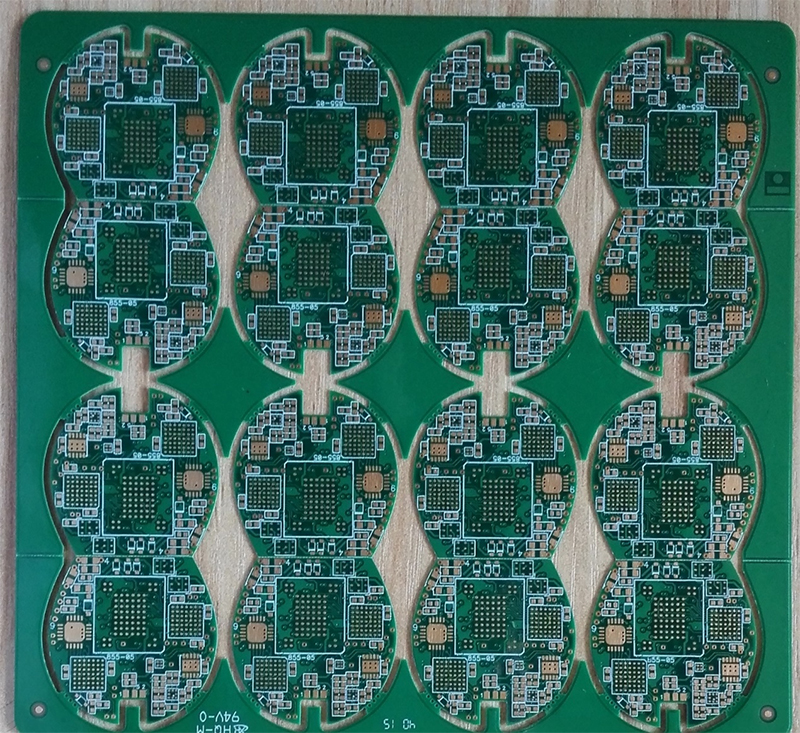

PCBs, on the other hand, differ significantly in that the board's circuitry is constructed of conductive ink. The design, development, and mass production of printed circuit boards are all areas of expertise for reputable printed circuit board manufacturers. And as was already mentioned, they must be built with care, with a close eye to ensure they leave the manufacturing line error-free and manufactured to perform flawlessly for a very long time. The fact that such sophisticated and sensitive circuits continue to work properly is evidence of the expertise and competence of the PCB designers and engineers, whose professions carry a great deal of responsibility.

Along with the designer's talent, the circuit board printing process must use high-quality equipment, otherwise, the engineers' hard work and devotion would be for naught. Printed circuit boards aren't always produced as single boards, even though this is frequently how we recall them from our childhood. Between two and 10 layers can be used to construct them. Given that copper is such an effective electrical conductor; it is typically used for electrical circuits.

These printed circuits' principal purpose is to make that the device's main processor is connected to all of its numerous parts. The printed circuit boards created for use in computers are an excellent example. The main circuit board, or motherboard, is connected to several smaller ones inside the computer that perform other related tasks.

To consistently produce printed circuit boards of the greatest quality, PCB makers must employ the most up-to-date technology and make sure the products are perfectly constructed. This is because so much essential equipment in our lives depends on the printed circuitry within. However, they wouldn't be able to fulfill the necessary high standards without employing the best raw materials, and choosing good materials will guarantee that the circuits remain corrosion-free throughout the product's working life.

The critical systems on which we rely every day may simply stop functioning properly in the absence of strong standards from the Printed Circuit Board Manufacturer.

The printed circuit board is known as PCB. This board is a crucial component of contemporary electrical devices. A printed circuit board is made up of a sizable number of both active and passive components. Traces on the board are used to link the components side to side. With the advent of extremely small-sized electronic components, it is possible to create very massive circuits on small printed circuit boards.

Benefits

- It is inexpensive making mass manufacture possible at a reduced price.

- It can be changed.

- Widely accessible

- Fantastic shelf life

- Low electronic noise is produced by this board.

- Compact size and wire conservation.

- The elimination of mistake likelihood by PCBs reduces the amount of time needed for inspection.

- Using this board instead of the traditional way speeds up circuit assembly

- There is no possibility of a short circuit or loose connections with this design.

- It is quite simple to inspect for damage and swap out the specific components that failed.

- To provide consistency of electrical properties from assembly to assembly, printed circuit boards are designed.

- The placement of the electronic component is fixed, making it simple to identify its components and perform equipment maintenance.

- In a factory that makes circuit boards, component wiring and assembly can both be automated.

- The performance of the circuit is reliable thanks to all of the aforementioned aspects.

Copper-clad PCBs

One of the most economical methods for producing hobby or prototype printed circuit boards is to use copper-clad boards (PCB). The printed circuit board tracks that link the circuit's components are soldered to a copper-clad board, which is a laminate of copper and a non-conductive substrate. They may be turned into professional-looking boards at a reasonable price using common home items.

Pros:

- Cheap: Making your board from a copper clad is frequently less expensive than ordering a prototype batch from a manufacturer, as they frequently charge a setup fee or base price, which isn't a problem when purchasing a large volume as it represents a small portion of the overall order, but it can be as much as ten times the price of a copper clad when purchasing one or two boards, plus shipping.

- Rapid: Placing an order with a manufacturer might be time-consuming. The majority of purchases are dispatched in five to six days for the standard shipping option, but if you need a board quickly, you should be prepared to spend significantly more and wait two to three days for delivery. It takes relatively little time to create a board out of a copper clad, especially if you already have the necessary supplies at home or in the lab.

- Customizable: Creating bespoke shapes and sizes is a huge benefit of making your copper-clad Printed Circuit Board, something that most manufacturers can't accomplish or will do at outrageous prices. This provides you the freedom to create extremely tiny boards or fit your circuits into strange shapes.