PCB Assembly: The Basics and Benefits Explained

Keywords: PCB Assembly China

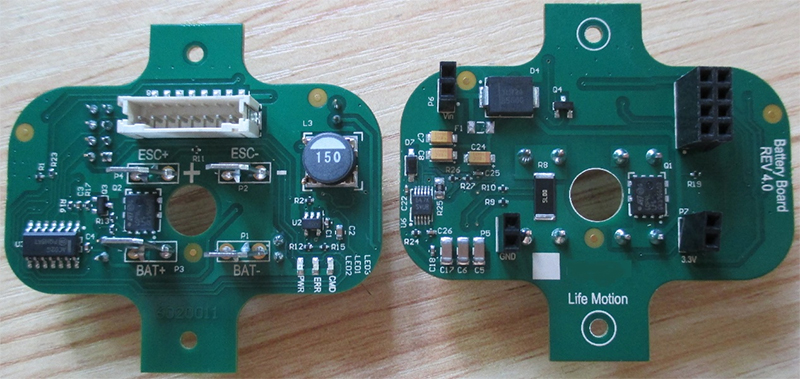

Printed Circuit Board (PCB) assembly involves various steps, from component placement to soldering and inspection, to ensure a functional and reliable product. In this blog, we will explore the basics of PCB Assembly China and the various methods used in the industry.

Types of PCB Assembly

PCB assembly mostly uses two techniques:

Through-Hole Assembly: This method involves inserting component leads into drilled holes in the PCB and then soldering them to the opposite side. Through-hole assembly is relatively simple and inexpensive, but it has limitations on component density and requires additional drilling for each new component.

Surface Mount Assembly: In this method, components are mounted directly on the surface of the PCB using solder paste and a pick-and-place machine. Surface mount assembly allows for higher component density, smaller PCB sizes, and automated assembly, but it requires more precise soldering and inspection.

Steps Involved in PCB Assembly

The following steps are involved in PCB assembly:

- Component Placement: In this step, the electronic components are placed onto the PCB according to the design specifications. For through-hole assembly, the components are inserted into drilled holes, and for surface mount assembly, the components are placed onto solder paste on the PCB surface using a pick-and-place machine.

- Soldering: Once the components are placed on the PCB, the next step is to solder them to the PCB to create a permanent electrical connection. Soldering can be done manually, using a soldering iron and flux, or using automated machinery. The solder must be applied correctly to ensure a reliable connection.

- Inspection: After the soldering is complete, the PCB Assembly China undergoes visual inspection to ensure that there are no soldering defects such as bridges, cold joints, or insufficient solder. Automated optical inspection (AOI) and X-ray inspection are also commonly used to detect defects that may not be visible to the naked eye.

- Testing: Finally, the PCB assembly is tested to ensure that it functions correctly. Functional testing may involve applying power to the board and measuring the output of various components to verify that they are functioning correctly.

Benefits of PCB Assembly

PCB assembly offers several benefits over hand-wiring electronic components. Here are some of the advantages:

- Consistency: PCB assembly ensures that the electronic components are consistently placed and soldered in the same way, which improves the reliability and consistency of the final product.

- Efficiency: PCB assembly can be automated, which increases efficiency and reduces labor costs. It is therefore perfect for mass production.

- Cost-Effective: PCB assembly can be cost-effective, particularly for large production runs. By using automated machinery, the production process can be streamlined, which reduces the per-unit cost of each PCB assembly.

Conclusion

PCB Assembly China is a critical process in the production of electronic devices. Whether you are creating a small prototype or mass-producing electronic devices, PCB assembly is an essential step that must be carefully executed. By following the steps above and choosing the right assembly method for your needs, you can create reliable and high-quality electronic products that meet your specifications.