PCB Assembling Methods and Significance of PCB Assembly Service

Keywords: PCB Assembly, PCB Assembly China

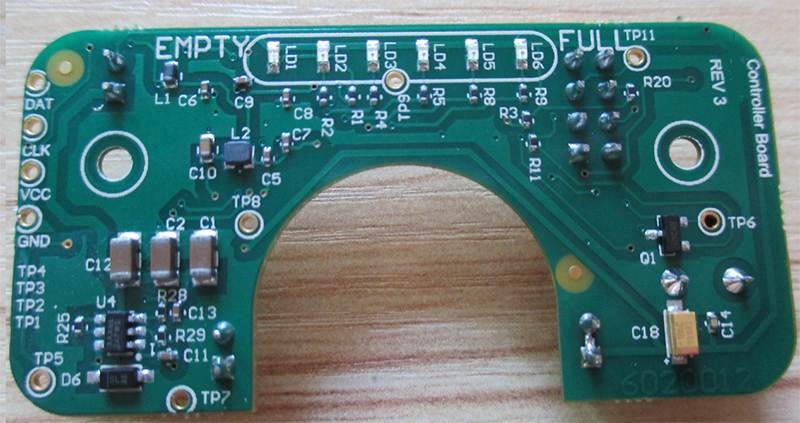

PCB Assembly is the attaching of electronic components to a printed circuit board. Using tracks, traces, or conductive pathways, PCBs are used to mechanically support and connect electronic components. From copper sheets laminated onto a non-conductive substrate, these are etched.

To produce a printed circuit assembly, electronic components can be attached once the PCB is completed. Through holes in the PCB, The leads of the components are inserted and the electronic components are placed on pads or land on the outer surfaces of the printed circuit board in surface mount construction. To the PCB, the component leads in both types of this construction are then mechanically fixed with soft metal molten solder.

For attaching components to printed circuit boards, there are all kinds of various techniques and by reflow ovens or bulk wave soldering and machine placement, most very high volume production is generally produced.

Sometimes, to solder very small parts by hand under a microscope, very skilled technicians are employed. By a very fine soldering tip and using tweezers, this is achieved. Soldering some parts such as ball grid array packages by hand is impossible.

To offer clients required suggestions and ideas on design, they have experienced staff. Reducing costs and improving the manufacturing process, these staffs use their extensive knowledge so that the process moves forward comfortably towards the placement of order.

On a single printed circuit board, through the hole and surface, mount construction must be combined very often. This is because, in surface-mount packages, some of the required electronic components are only available while in through-hole packages, others are only available.

Surface mount techniques will go largely unstressed and take up less space, which is why one of both methods is used. For any components, needed strength to endure any physical stress can be offered by through the hole mounting. It can be tested in a number of different ways when the PCB or printed circuit board has been populated or built with the desired components, and these may include:

- Power on; verifying if the PCB is performing in an intended way in functional test

- Power on; physical measurements in-circuit test,

- Power off; automated optical and visual inspection

- Power off; analysis of analog signature in power off testing

By spraying or dipping, a conformal coating might be applied by some printed circuit boards once the components have been soldered. A protective layer is provided by this coating which helps prevent leaking current and corrosion due to condensation. Too static, Assembled PCBs are sensitive. Antistatic plastic bags are often placed for transport or handling purposes.

Assembling Method

Based on the device it has to be installed into, various electronic boards have different assemblies involved. Involved in the making of PCB Assembly China, there are two major types of manufacturing approaches:

- Surface-Mount approach: On the external planes of the electronic board, the apparatuses are installed in this approach.

- Hole-through approach: the apparatuses are implanted into the holes in this approach

With the help of a metal solder, the apparatuses are installed on the printed circuit board by using electricity, which is the only similarity between both approaches. How the apparatuses have to be fused on the board is decided by the capacity of the board. It is always advisable to make use of machines in case of manufacturing more quantity of circuit board assemblies. By using a reflow oven as well as wave soldering, the circuit placement on the machine is done. With reflow ovens or bulk wave soldering, machine placement is done. One can always opt for hand soldering in case of small-scale production.

In a single assembly, both surface mount approach, as well as hole-through approach, have to be applied sometimes. This is due to the fact that only in hole-through sets, some electronic components are obtainable and others are obtainable in surface-mount packages. During the assembling process, it proves to be beneficial when both approaches are used.

Just in case they have some physical damage, the hole through installation makes electronic components robust. However, using the surface mount approach is better when you are aware that any damage has less chance to occur. Less area on the electronic board is used by the surface mount approach.

It is important to check whether the board performs the function needed and is working properly as soon as the assembling process is over. Finding out the source of the issue is very easy and replacement can be done in case of a failure on the part of the printed circuit board.

For the mechanical support of any type of electronics product, PCB is required. This is in the form of a board or a card, which is made up of hard plastic or thin metal commonly known as the insulator. On the board or this card, the chips of the electronic devices are mounted. From the larger electronics devices like the television and computer to the smallest device like the mobile, The PCB is used. When no components are fitted onto the board, it is known as PCB but, it is known as PCB assembly service when electronics components get mounted.

Requirement of PCB Assembly Service

Many changes are taking place in the operational functions of all the electronics devices in the modern world as technology is developing at a fast rate. Thus, the old model electronic components are getting outdated and their components are not easily available. Thus, getting a new model or updating the existing one becomes crucial at this point whether at home or office.

Rather than purchasing a new model, the device can be updated at a lower cost if the new PCB board or card which is mounted with the latest chips is fitted in the electronics device and the PCB Assembly service is changed. This is due to the fact that the old models’ resale value is very low. In three types, these boards are available which are multi-layered, double-sided, or single-sided.