Multilayer PCBs Benefits over Single Layer Alternatives

Keywords: Multilayer PCB

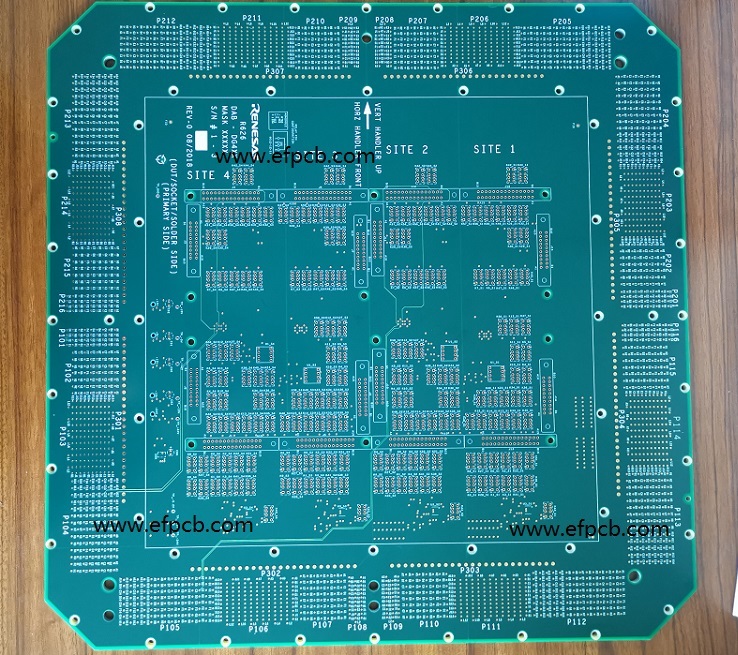

The majority of modern electronics are built on printed circuit boards (PCBs), which determine fundamental functions by combining parts and wiring techniques. The majority of PCBs from earlier times were very straightforward and constrained by manufacturing methods, but PCBs from today are significantly more complicated. In today's electronics industry, PCBs are significantly more diversified, ranging from cutting-edge flexible alternatives to odd-shaped types. Multilayer PCB, however, is particularly well-liked.

While more complex electronics, like computer motherboards, often have numerous layers, simpler electronics with fewer functions typically have a single layer of PCBs. These are multilayer PCBs, as the name suggests. These multilayer PCBs are now more common than ever, and they may be made smaller thanks to advancements in manufacturing technology and the complexity of current electronics.

Continue reading to find out more about multilayer PCBs, their applications, and their benefits in the field of contemporary electronics.

A Multilayer PCB

A PCB that is constructed with three or more conductive copper foil layers is referred to as a multilayer PCB. These resemble many double-sided circuit board layers that have been laminated, bonded, and separated by layers of heat-resistant insulation. Two layers are put on the PCB's surface sides to link to the environment during the complete construction. Vias, such as plated through holes, blinds, and buried vias, are used to provide all electrical connections between the layers. The use of this technique leads to the production of incredibly complex PCBs in a range of sizes.

The multilayer PCB was created as a result of the electronics industry's ongoing advancements. Electronic functions have evolved throughout time, becoming more complicated and necessitating increasingly complex PCBs. PCBs were unfortunately constrained by issues like noise, stray capacitance, and crosstalk, necessitating the observance of certain design restrictions. Due to these design factors, it was challenging to get an acceptable level of performance from a single-sided or even double-sided PCB; as a result, the multilayer PCB was created.

Due to the fact that they provide double-layer PCB power in a considerably smaller size, multilayer PCBs are becoming more and more common in electronics. To meet the demands of their growing uses, they are available in a variety of shapes and sizes with thicknesses ranging from four to twelve layers. Since odd numbers of layers might cause problems in the circuit like warping and are not more cost-effective to fabricate, even numbers of layers are often used.

Multilayer PCBs are becoming an indispensable component of contemporary technology, even though they are often more expensive and labor-intensive to create. This is large because they have a wide range of advantages over single- and double-layer variants.

Benefits of Multilayer PCBs

From a technological perspective, multilayer PCBs provide several design benefits. These benefits multilayer PCBs provide include:

- Small Size: Multilayer PCBs' small size is one of its most notable and acclaimed advantages. Due to their layered design, multilayer PCBs are inherently smaller than conventional PCBs with equivalent functionality. As the current trend is toward smaller, more portable, yet more powerful technology like smartphones, laptops, tablets, and wearables, modern electronics will substantially benefit from this.

- Lightweight Design: A multilayered design eliminates the need for many connectors needed to interconnect separate single and double-layered PCBs, resulting in smaller PCBs that are lighter in weight. Again, this is advantageous for contemporary electronics, which are more oriented on portability.

- High-Quality: Multilayer PCBs are often of higher quality than single- and double-layer PCBs because of the extensive labor and planning required to create them. As a result, they frequently become more trustworthy.

- Enhanced Durability: Multilayer PCBs are often more robust by nature. These multilayer PCBs must be able to endure the heat and pressure needed to bind them together in addition to their weight. In addition to these elements, multilayer PCBs bind everything together using Prepreg bonding agents and protective materials and employ numerous levels of insulation between circuit layers.

- Increased Flexibility: While not all multilayer PCB assemblies fall under this category, some do employ flexible manufacturing methods, resulting in a flexible multilayer PCB. For situations where light bending and flexing may happen occasionally, this quality might be quite desirable. Again, this is not true for all multilayer PCBs, and a flexible PCB loses flexibility as more layers are added to it.

- More Effective: Multilayer PCBs include numerous layers into a single PCB, making them highly high-density assemblies. Boards are more connective because of the close quarters, and despite their small size, they can work at higher capacities and speeds thanks to their intrinsic electrical properties.

- Single Connection Point: Unlike other PCB components, multilayer PCBs are made to function as a single unit. They only have one connection point as a consequence, as opposed to the several connection points needed to employ numerous single-layer PCBs. Since there is just one connecting point required in the finished product, this also works to the benefit of designers of electrical products. This is especially advantageous for small electronics and devices made to be light and compact.

Multilayer PCBs provide advantages over single-layer alternatives.

The benefits of multilayer PCBs are much more obvious when compared to single-layer substitutes. The following are some of the main enhancements multilayer PCBs provide:

- Higher Assembly Density: Multilayer PCBs have an increased density due to stacking, but single-layer PCBs' density is constrained by their surface area. Despite the reduced PCB footprint, the increased density enables greater functionality, enhancing capacity and speed.

- Smaller Overall Size: Compared to single-layer PCBs, multilayer PCBs are often smaller. Multilayer PCBs enhance surface area with the addition of layers, but single-layer PCBs must expand the circuit's size to increase surface area. As a result, higher-capacity single-layer PCBs can only be utilized in bigger goods, while higher-capacity multilayer PCBs may be used in smaller devices.

- Lighter Weight: Because components are integrated into a multilayer PCB, fewer connections and other components are required, making this a lightweight option for intricate electrical applications. Multilayer PCBs may perform the same tasks as several single-layer PCBs, but they do so in a smaller space and with fewer connecting parts, resulting in a lighter board. This is a crucial factor to take into account for smaller devices when weight is an issue.

- More Functional Design: In general, multilayer PCBs have more potential than the typical single-layer PCB. Multilayer PCBs may do more despite being smaller and lighter because of the increased use of controlled impedance features, more EMI shielding, and overall enhanced design quality.

In essence, a Multilayer PCB is probably your best option if you want to create a compact, lightweight, sophisticated gadget where quality is crucial. However, a single or two-layer PCB design may be more cost-effective if size and weight are not the main design considerations for your device.