Microvia PCBs: Revolutionized Component in the Electronics World

Keywords: Microvia PCB Companies

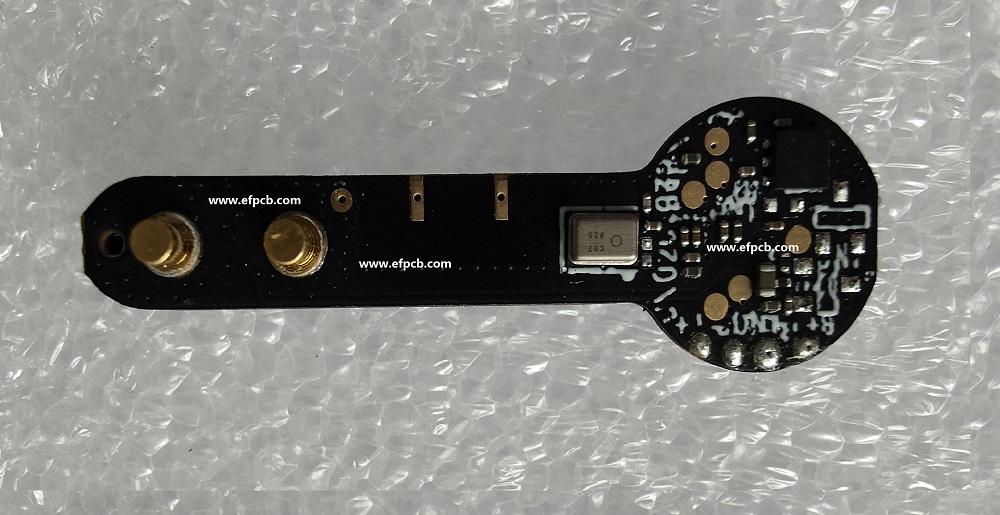

Microvia PCBs, as the name suggests, are PCBs with tiny vias or holes. These vias are significantly smaller than the through-hole vias used in traditional PCBs, often measuring less than 0.15 millimeters (150 microns) in diameter. Microvias are created using advanced drilling techniques, such as laser drilling or mechanical drilling, and are typically located on the inner layers of the PCB from Microvia PCB Companies.

There are two primary types of microvias: blind vias and buried vias.

- Blind Vias: These vias start on one surface of the PCB and extend partially into one or more inner layers. They are useful for making connections to specific layers without penetrating the entire board.

- Buried Vias: Unlike blind vias, buried vias do not extend to the outer layers of the PCB. Instead, they connect one or more inner layers, providing a high level of routing flexibility.

Microvia PCBs have become the go-to choice for many high-density and high-performance applications due to their compact size, improved signal integrity, and enhanced reliability.

Advantages of Microvia PCBs

- Miniaturization

One of the most significant advantages of microvia PCBs is their ability to support miniaturization. As electronic devices continue to become smaller and more compact, traditional through-hole vias are no longer suitable. Microvias enables designers to pack more components into a limited space, making them ideal for applications like smartphones, tablets, and wearables.

- Improved Signal Integrity

Microvias also offer improved signal integrity. With shorter trace lengths and reduced parasitic capacitance and inductance, signals can travel faster and with less distortion. This is crucial in high-speed applications like data centers and high-frequency communication systems.

- Enhanced Reliability

The reduced size of microvias translates to smaller drill holes, which are less prone to mechanical stress and drilling-induced defects. This leads to increased reliability and a lower likelihood of failures, especially in harsh operating environments.

- Higher Routing Density

Microvia PCBs allow for higher routing density, meaning more traces and components can be accommodated on the same board. This is a game-changer for complex and densely populated PCBs, such as those found in advanced medical devices and aerospace applications.

- Reduced Weight

In applications where weight is a critical factor, such as aerospace and automotive industries, microvia PCBs offer a lightweight solution. Their compact design reduces the overall weight of the PCB assembly, contributing to fuel efficiency and improved performance.

Applications of Microvia PCBs

The versatility of microvia PCBs has led to their adoption in a wide range of applications across various industries. Here are some notable examples:

- Consumer Electronics

Microvia PCBs are extensively used in consumer electronics, including smartphones, tablets, laptops, and smartwatches. Their ability to support miniaturization allows manufacturers to create sleek and compact devices without sacrificing performance.

- Aerospace and Defense

In the aerospace and defense sector, where reliability and performance are paramount, microvia PCBs are a natural choice. They are used in avionics, radar systems, satellite communication equipment, and military-grade electronics.

- Medical Devices

Medical devices, such as pacemakers, medical imaging equipment, and diagnostic devices, often require high-density PCBs with precise routing. Microvia PCBs are well-suited for these applications, ensuring the devices are both reliable and compact.

- Automotive

The automotive industry has embraced microvia PCBs for their lightweight and compact design. They are used in advanced driver assistance systems (ADAS), infotainment systems, and engine control units (ECUs).

- Data Centers

Data centers demand high-speed and high-density PCBs to handle the massive amount of data processed every day. Microvia PCBs play a critical role in ensuring data transmission is fast and reliable.

Challenges and Considerations

While microvia PCBs from Microvia PCB Companies offer numerous advantages, they are not without challenges and considerations. Designing and manufacturing microvia PCBs can be more complex and costly compared to traditional PCBs. Specialized equipment and expertise are required for precise drilling and lamination processes. Additionally, the cost of microvia PCBs can be higher due to the advanced technology involved.

Designers must also consider factors like thermal management and material selection, as the smaller size of microvias can affect heat dissipation and the choice of substrates. Careful planning and collaboration with experienced PCB manufacturers are essential to overcome these challenges.

The Future of Microvia PCBs

The rapid development of microvia PCB technology shows no signs of slowing down. As we look to the future, several trends and advancements are likely to shape the landscape of microvia PCBs:

- Miniaturization beyond Imagination: With micro via PCBs already pushing the limits of miniaturization, it's only a matter of time before we see even smaller vias and denser interconnections. This will enable the creation of even smaller and more powerful devices, from medical implants to microscopic sensors.

- 5G and Beyond: The rollout of 5G networks and the development of 6G and beyond will require PCBs with ultra-high-frequency capabilities. Microvia PCBs are poised to play a pivotal role in these advanced communication systems, where signal integrity and speed are paramount.

- IoT Revolution: The Internet of Things (IoT) is ushering in an era of interconnected devices, and microvia PCBs will be at the heart of this revolution. These tiny boards will enable the seamless integration of sensors and communication modules into everyday objects, turning them into smart devices.

- Sustainable Manufacturing: The electronics industry is increasingly focusing on sustainability. Microvia PCBs, with their reduced material usage and lightweight design, contribute to greener electronics manufacturing. Expect to see more eco-friendly PCB materials and processes in the years to come.

- Quantum Computing: As quantum computing technologies mature, they will demand PCBs that can handle extremely low temperatures and complex interconnections. Microvia PCBs, with their precision and reliability, will find applications in this emerging field.

- Advanced Materials: Ongoing research in materials science is likely to yield new substrates and conductive materials that can enhance the performance of microvia PCBs. These materials may offer improved thermal management, higher conductivity, and enhanced reliability.

- AI-Enhanced Design: Artificial intelligence (AI) and machine learning are being employed to optimize the design and layout of PCBs. AI-driven design tools will become more sophisticated, helping engineers make the most of microvia technology.

- Global Collaboration: The global nature of the electronics industry will continue to foster collaboration between companies and research institutions worldwide. This collaborative effort will lead to faster innovation and the development of new microvia PCB applications.

Conclusion

Microvia PCBs from Microvia PCB Companies represent a significant leap forward in PCB technology, enabling smaller, more reliable, and higher-performance electronic devices. From consumer gadgets to critical aerospace systems, microvia PCBs have found their way into a wide range of applications, reshaping the electronics industry in the process.

As technology continues to advance, microvia PCBs will likely become even more prevalent, driving innovation and pushing the boundaries of what's possible in electronics design. Their ability to support miniaturization, improve signal integrity, and enhance reliability makes them a cornerstone of modern electronics manufacturing, and their future looks brighter than ever.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top HDI PCB Manufacturers (2024)

- 6Top 10 Flexible PCB Factories in 2025

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact