Manufacturing of High-volume PCB and Its Benefits

Keywords: High Volume PCB

In today's world, circuit boards have evolved into a crucial part of every electronic gadget and piece of machinery. The value of PCBs will only rise over time as our reliance on electronics for numerous purposes, from our homes to offices, increases. We are amazed by the evolution of circuit boards from the time of breadboards to the modern intricate, miniature PCBs.

High Volume PCB assembly and mass production are crucial as long as our electrical needs depend significantly on PCBs. To satisfy these requirements, it's essential to choose a high-volume printed circuit board manufacturer that is perfect. This article covers all the information you need to know about producing several PCBs.

Assembly and High-Volume PCB Manufacturing

Both seasoned professionals and newcomers to the PCB sector may be perplexed by the subject of high-volume printed circuit board assembly and fabrication. Understanding what high-volume printed circuit board fabrication and assembly requires is crucial.

• Production of High-Volume PCBs

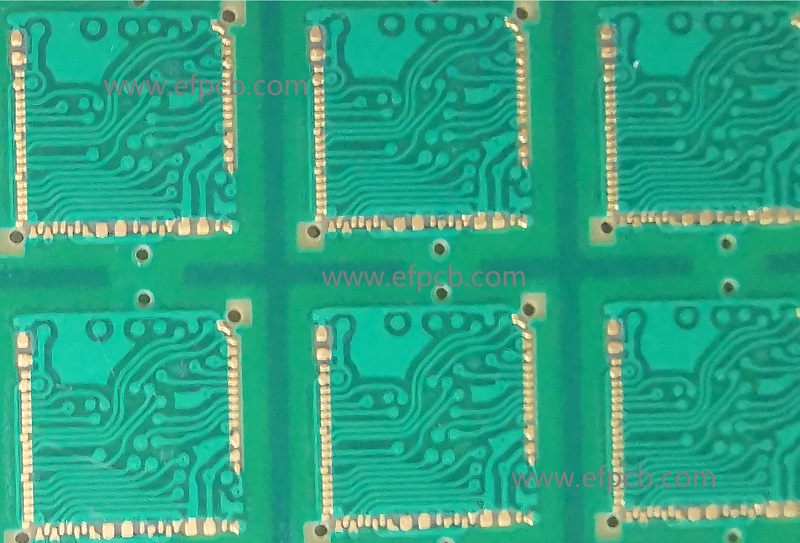

The final stage of PCB manufacture before delivering to clients is high-volume printed circuit board fabrication. High numbers of PCB are produced by a linear process with no layout adjustments. The goal of this process is to generate high-quality printed circuit boards at the lowest cost while keeping up a rapid production rate to satisfy the demands of the client.

• Large-Scale Assembly

High-volume printed circuit board assembly requires the creation of more than ten thousand PCB parts while taking Design for Manufacturing (DFM) and Design for Testing (DFT) into account (DFM). When hiring a printed circuit board firm for mass production, it is crucial to know the sort of printed circuit board that is needed. Otherwise, there is a chance that there will be a lot of high-quality PCBs that do not satisfy the particular requirements of the electronics. So, selecting the right PCB is crucial since it may greatly affect functioning.

Increasing the Production of High-Volume PCBs

It is essential to streamline the low-volume formation process, which frequently entails the PCB prototyping stage, in order to increase the efficiency of the large-volume printed circuit board manufacture & assembly process.

Although the quality of small-volume printed circuit board manufacture significantly depends on their equipment & skill in meeting the unique design requirements, you should think about choosing an experienced contract producer for your PCB design.

It's crucial to adjust your PCB design to the capabilities of your contract manufacturer in order to guarantee timely delivery, minimize redesigning, and save money on additional development expenditures. This entails using requirements that are compatible with the contract manufacturer's machinery capabilities.

Optimizing your component selection is crucial if you want to prevent production pauses or delays. Component shortages are a frequent cause of delays, thus it is vital to make sure that all relevant information is easily available and of appropriate quality to support your anticipated production volumes.

Observe appropriate DFM rules. The low-level development of your PCBs may be greatly aided by adhering to DFM recommendations particular to your contract manufacturer, which will eventually enhance your large-volume printed circuit board production & assembly process.

Carry out the mandatory PCB testing. It is crucial to ensure that all relevant regulatory testing is done on your PCBs following the prototype process. It is advised to go above and above by doing additional tests to confirm that elements like structural integrity are sound.

Your PCBs' high-volume formation and assembly processes will be optimized if you can increase efficiency during the low-volume formation phase by paying attention to the specifics. It’s crucial to bear in mind that the initial stages of creating a large number of circuit boards are crucial since they provide the foundation for creating a large number of them later on.

Prototype to High-Volume PCB Manufacturing: A Transition

Ideally, the transition from PCB prototyping to manufacturing stage to mass or large volume creation should be simple and seamless. Nevertheless, difficulties might occur during this shift, such as the requirement to revise layout files in order to build PCBs of superior quality. Without the right design files, it may be more expensive to produce high-quality printed circuit boards, which would take more time and money.

Other serious issues, such the need to collect and transmit additional layout files from the prototype producer to the contract producer, may emerge as a result of a lack of layout data. Also, the contract producer might not be able to create your PCBs in accordance with the precise guidelines provided by the prototype maker. Components going missing during the printed circuit board fabrication phase are not unusual. Moreover, design modifications can be necessary, particularly if there are operational and performance shortcomings that call for re-prototyping and redesigning.

Advantages of High-Volume PCB Production

High-volume PCBs have a wide range of important advantages, including the following:

Prototyping and design tasks are combined during high-volume PCB assembly to ensure that the model is painstakingly created and checked for accuracy. This makes it easier to begin a lengthy formation run.

The ability to produce PCB items on a big scale is made possible by high-volume printed circuit board assembly, which is very advantageous for breaking into the mass market. It guarantees the rapid turnaround and production of numerous high-quality PCB items. This situation is great for entering the market rapidly and getting an edge over other businesses.

Due to economies of scale, producing PCBs in huge volumes has various cost-related advantages. A more economical finished product might arise from reduced production costs caused by mass production. Your PCB's pricing will be influenced by the cost of manufacture, which will eventually effect how competitive you are in the market. Production in huge volumes can benefit from economies of scale, which lowers costs. This contrasts with manufacturing and assembly in small quantities, which frequently results in price increases.

Due to automation, high-volume PCB fabrication and assembly may drastically reduce the production cycle. The manufacturing pipeline and go-to-market strategy may profit considerably from this simplified approach, giving the electronics industry a competitive edge.

Large volume PCB production guarantees that goods have consistent and uniform characteristics. This is due to the consistent assembly and testing procedures that each PCB goes through, which ensures the end product's high quality. Low-volume manufacturing presents a higher risk of mistakes and inconsistencies; mass production enables the contract manufacturer to apply standardized production techniques.

Final Words

Particularly for amateurs and businesses active in creating and building electronic products, PCB manufacture and assembly are essential components of the electronics industry. As a result, printed circuit board manufacture and assembly are essential. Choose Efpcb High Volume PCB now for a delightful experience if you are interested in such services.