Learn About the Basics of Heat Transfer in A Printed Circuit Board

Keywords: Printed Circuit Board Manufacturer, PCB Manufacturer, PCB Manufacturing

A printed circuit board or PCB is a plate or board that is specifically used for placing the different elements that meet the standards of an electrical circuit that has the electrical interconnections between them.

Today PCB with two layers is the common one that PCB manufacturer produces and in both surfaces of the board you can find out the interconnections.

Basics of Heat Transfer

On a fundamental level, discussion about heat transfer includes two topics: temperature and heat flow. Temperature indicates the level of thermal energy that’s available, while heat flow says that thermal energy moves from one place to another.

You will come across few material properties that can modulate heat quite effectively which are being transferred between two areas at different temperatures. These are fluid viscosities, thermal conductivities, fluid velocities, and material densities. When these properties are combined they make the heat transfer problem much more complicated. Printed Circuit Board Manufacturer is easily available nowadays.

Process of Heat Transfer

In three broad categories heat transfer mechanisms can be grouped:

Radiation- Every material gives off thermal energy in amounts that can be determined by temperature. The radiation flux is in equilibrium between objects when the temperature is constant, and no exchange of thermal energy is happening.

Conduction- Thermal energy is transferred from Areas that have more molecular kinetic energy to areas that have less molecular energy. This process takes place through a direct collision of molecules, known as conduction.

Convection- In an electronic device when heat is generated, it’s transported through conduction to an area where it is then transferred to a fluid.

Design Techniques of PCB in Transfer of Heat

Copper pours- In the PCB any component can connect to the ground with ease only when the unused areas are filled with metal and ground metal.

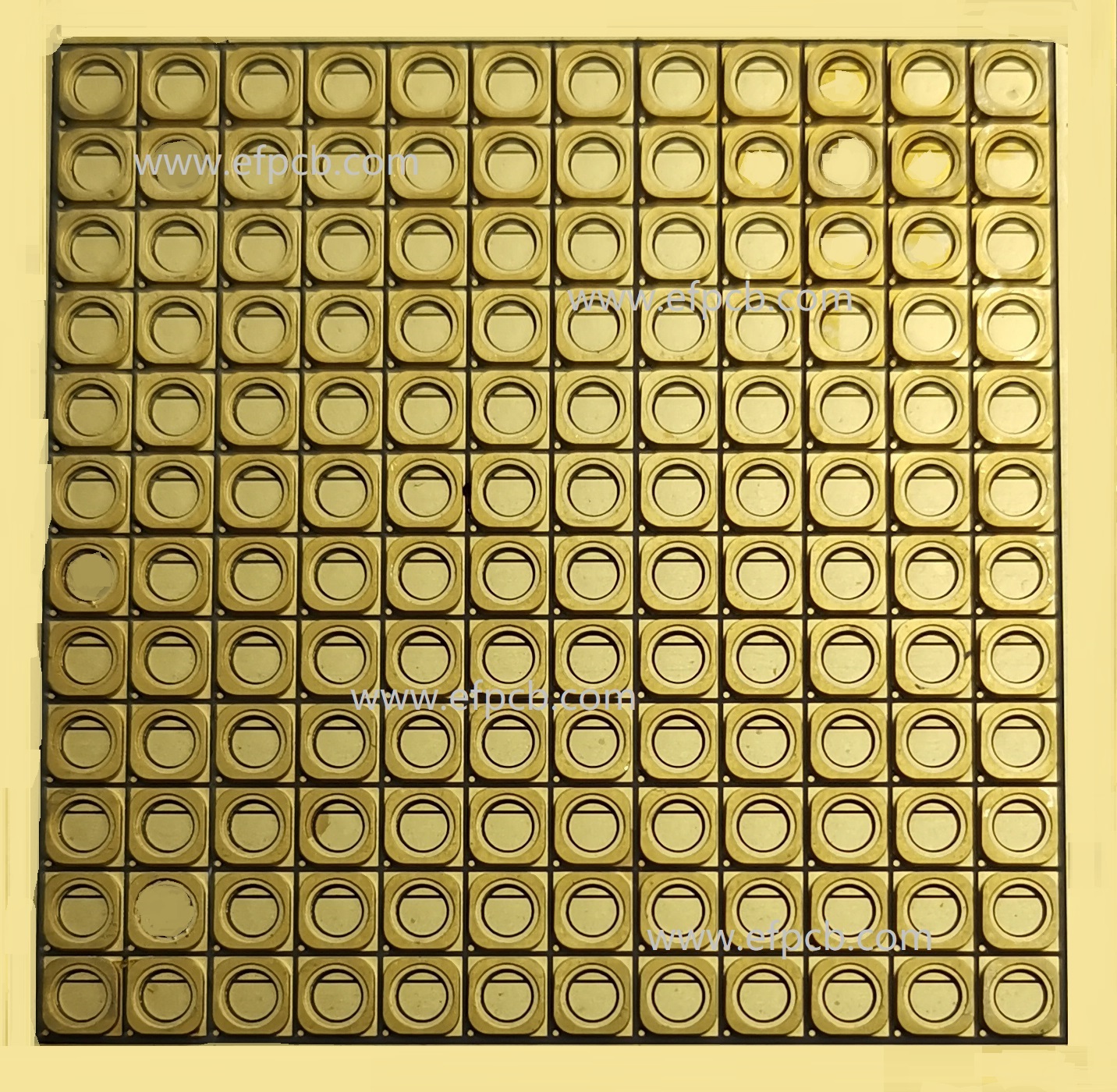

Thermal vias- Thermal vias help in creating a pathway to the copper and the PCB components.

Heat sinks- Large metallic pieces with high conductivity are used in this technique. To the parts that produce heat the pieces are attached as a result they expose more surface area to the air. Thermal resistance is lowered through this setup, and then enhancement of heat flow is done with a cooling fan.

Higher Thermal Conductivity Materials- In improving the thermal conductivity of the PCB Materials like aluminum, ceramics, and copper core are used. Today PCB Manufacturing is done with greater efficiency.