Learn about Printed Circuit Boards

Keywords: Printed Circuit Board, Printed Circuits, Circuits Board

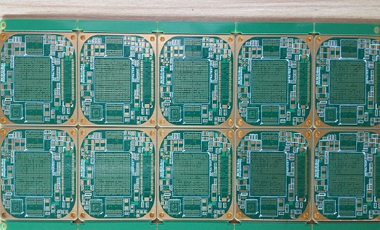

Printed Circuit Board

Everybody once in the course of their life has opened up a piece of electronic hardware and has seen a printed circuit board, which is alluded to as a PCB. They are very slim, level, and have green rectangular substrates which are covered with a labyrinth of fine copper lines and silver cushions. They are viewed as the essence of most extreme electronic hardware. To comprehend all that about circuit sheets then it requests finding out about what they are, the various sorts of circuit sheets that exist, the various kinds of parts utilized on these circuit sheets, and the strategies and cycles engaged with PCB Assembling. To begin with, you should know how the advancement of printed circuit board has occurred.

During the time of 1950s, printed circuit loads up supplanted highlight point development in a limit of gadgets. Highlight point development used wires that are bound to terminal strips and sheets that are stepped with metal circles. In a gadget that performed on the money to-point activity, a few little electronic parts and their wires were straightforwardly fastened to their terminals, similar to the way the wires from the bigger gadgets, like transformers. As you can envision, this framework incorporated a confounding knot of wires. It was not by any stretch simple to involve them in large scale manufacturing as each wire and part must be circled and welded to the right part on the terminal strip.

In Printed Circuits Assembling, wire wrap is one technique that was exceptionally famous during the 1960s. On a protecting load up, the mounting of electronic parts was finished and afterward they were interconnected by wire, and the wire was folded a few times over leads or attachment pins.

Enter the PCB, which performed well with practically the wiring that was all utilized in highlight point development and wire wrapping, and thusly it worked with large scale manufacturing. You can without much of a stretch mechanize the PCB fabricating process as it diminishes the gamble of designing blemishes that would have brought about bombed models or defective sheets. A PCB producer can take care of the determinations into programming that runs immense plan checks so it can ensure that the board is giving ideal execution before it is even created. Mechanized creation even shows lower costs when contrasted with other development techniques.

This article mirrors light on the various kinds of circuits board, the parts that are utilized on the sheets, the different PCB producing techniques, and contemplations associated with PCB creation.