Learn About Flexible Printed Circuit Design Errors

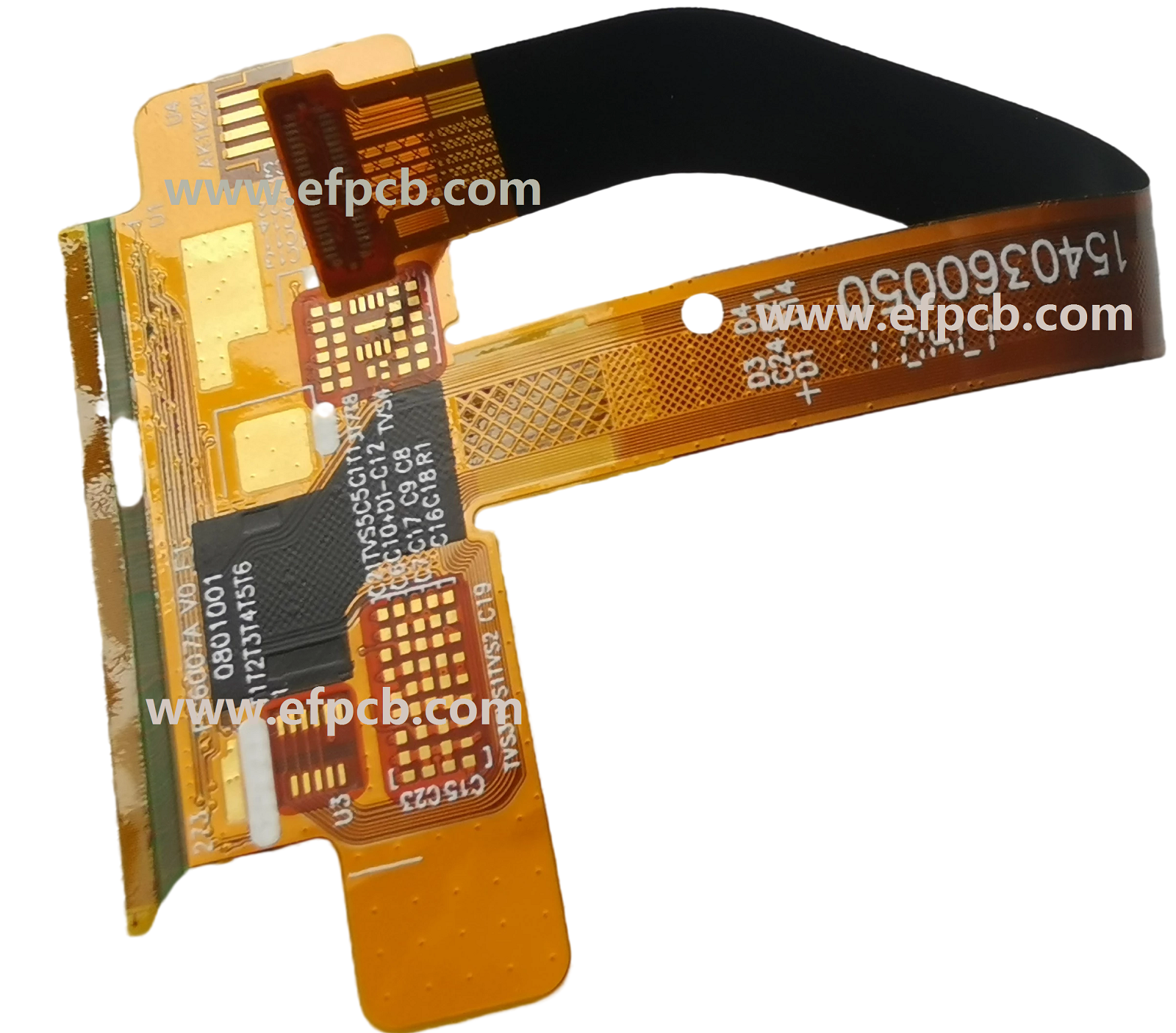

For the packaging engineer and electronic designer Flexible Printed Circuitry (FPC) offers a tremendous opportunity. Into endless dimensional configurations, these versatile electronic wiring systems can be bent, twisted, shaped, and folded limited that to only by an engineer's creativity. However, over a two dimensional and inflexible Backplane board they offer significant design advantages.

More dimensionally stable are the rigid printed circuits but in 98% of the flex circuits produced the standard polyimide film is used as the building block. The increase in dimensional variability indicates that compared to its rigid printed circuit board relative, a flexible circuit needs different design rules. Hard Gold PCB is also very reliable.

The major advantage of using this type of PCB assembly service is the ability to create a high-quality board with soldering at an expert level. Professional service becomes more effective with kind of setups that have a lot of surface-mounted components.

Few common ways that makes a design more robust, more producible, and ready for fabrication.

Adjacent Traces and Solder Pads Spacing for PCB Assembly

Here is the tradeoff, i.e. design compromise, which will be prepared based on item. When the cover film or solder mask openings are made larger, the adjacent conductor edge traces get exposed but only when too close to a solder pad, they are routed.

Stacked traces- Traces present on the opposite sides of the dielectric should not directly stack on each other. When the circuit is bent traces in tension (on the outside of the bend radius) may crack but it only happens when they are directly aligned in parallel with a trace on the opposite side. From the neutral axis of the folded region, the traces in tension are forced farther and they can even get a fracture, especially with repeated bending.

Solder mask or cover film openings- During fabrication after exposure to processes like pumice scrubbing, copper plating, and/or etching flexible, the circuitry can demonstrate dimensional change. Flexible circuitry design rules usually need huge tolerances to accommodate subsequent registrations for die-cutting, cover film or stiffeners.

The major point is with Metal Core PCB software designing a flex circuit can result in some serious manufacturability and reliability issues.