Know Some Common Flexible Printed Circuit Design Errors

Keywords: Flexible PCB, Flex Circuits Board

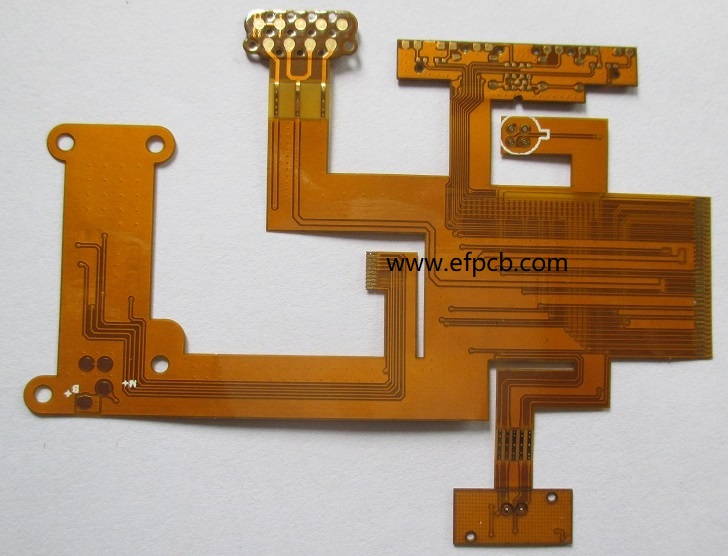

The packaging engineer and electronic designer are offered a good opportunity by Flexible PCB. You can shape, bend, twist, and fold these versatile electronic wiring systems into endless dimensional configurations.

Below is provided some common ways how Flexi zing can make a design more robust, producible, and ready for fabrication.

Spacing between solder pads and adjacent traces: You can expose the edges of the adjacent conductor traces when the openings of cover film or solder mask are made larger. This can result in causing shorts but only when solder bridges between connector pins or pads. To accommodate the cover film or solder mask placement tolerance there is a requirement of more space between a solder pad and an adjacent conductive trace.

Stress points in conductors: In both fields that is in installing and dynamic flexing applications there is the use of Flex circuitry but a rigid PCB may create problems in a Flex Circuits Board trace configurations. At the base of solder pads, conductor traces with sharp corners and acute junctures become natural stress points but the condition is that the area near them should be flexed. For conductor turn points a good flexible circuit layout will have a smooth radius.

Solder mask or cover film openings: Flexible circuitry can demonstrate dimensional change during the fabrication process but only after exposure to processes like pumice scrubbing, copper plating, and/or etching. The designs of flexible circuitry design rules need larger tolerances to accommodate subsequent registrations for cover film, stiffeners, or die-cutting.

Soldered joints too close to bending point: With the help of an intermetallic bond of the solder alloy to the copper trace, a solder joint is formed. However, the traces of the copper are normally flexible but the regions that have been soldered become very rigid and inflexible.

The main point is that with standard PCB software the designing a flex circuit can result in some serious manufacturability and reliability issues. It is always an excellent thing to work with your flexible circuit supplier or a flexible circuit design expert as they flex the design before beginning fabrication or it can create the layout directly from a netlist. This will make sure that to meet your needs the Flexible PCB design can be manufactured.