Know more about the Build Up process of Flex PCB

Keywords: Flexible PCB, Flex Circuits Board

The inflexible kind is the most well-known sort of Printed Circuit Sheets, yet one more sort that you might consider utilizing it is the flex one subsequent to getting yourself acquainted with.

Current electronic contraptions, with the development of Flexible PCB innovation, have made considerable progress. In the center of numerous fragile and delicate electronic items, they are found. This innovation is being utilized in even numerous electronic contraptions like your adding machines, camera, Cell phone, and workstations.

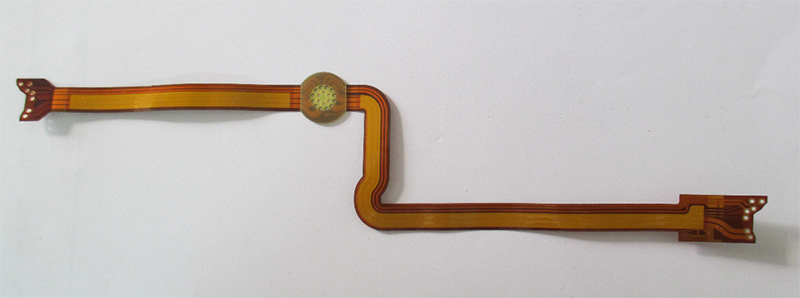

Adaptable PCB

From polyimide, it is made of a base substrate material. Both artificially and normally, this material is found and is utilized in different businesses like apparel, car, and so on impressive weight, space, and reserve funds is presented by the conservative idea of high electrical-association thickness and adaptable circuits when contrasted with the conventional unbending printed circuit sheets.

Develop of Flex PCB

Base material saving is the principal concern and this is the significant stage. For the flex circuit, the essential material utilized is Polyimide. This material is costly and should be utilized appropriately. You want to keep circuits near one another for suitable polyimide utilization, however much as could be expected utilizing the settling method. The accompanying cycles are associated with the model PCB producing:

Measuring guide: most noteworthy adaptability is given by it. In this manner, especially when you need to involve the circuit for dynamic applications, you want to choose the most slender copper.

Circling: Expansion past as far as possible measure of additional material is satisfactory. A help circle is this additional material that empowers the Flex Circuits Board get together and overhauling length.

Steering: Guides Directing of the can be effectively finished. To the crease and twist, absolutely get on the opposite position. By lessening pressure, this will further develop twisting and collapsing.

Scratching: for any isotropic misfortunes, this cycle is finished to repay in the assembling system. The copper foil thickness is around 50% of the line width misfortune during this interaction. A few elements influence the transmitter, different copper types, line width, scratch veil, and so forth.

Ground Planes: Assuming there is satisfactory electrical designation, ground regions are made crosshatched. In working on the adaptability of the Flexible PCB circuit, this guides by diminishing the circuit board weight.