Know More about Manufacturing Process of PCB

Keywords: PCB Fabrication, RF PCB

In various ways, the PCB fabricating cycle can be accomplished and various variations are there. The fundamental stages in the RF PCB fabricating process are something very similar notwithstanding the numerous little varieties.

RF PCB constituents

From various substances, Printed circuit sheets or PCBs can be made. In a type of glass fiber based board known as FR4, these are the most utilized broadly. Under temperature variety, this offers a sensible soundness degree and keeping in mind that not being unreasonably costly, it is doesn't seriously breakdown. For the PCBs in minimal expense business items, other less expensive materials are accessible. Where the dielectric consistent of the substrate is fundamental, low degrees of misfortune and radio recurrence plans are required for elite execution. Despite the fact that they are undeniably more hard to work with, PTFE based printed circuit sheets can be utilized.

Essential RF PCB producing process

Making the necessary tracks on the board and eliminating the undesirable copper is the following stage with the exposed PCB sheets picked and accessible. Utilizing a substance drawing process, the production of the PCBs is regularly accomplished. With PCBs, the most well-known type of engraving utilized is ferric chloride.

A visual cycle is utilized to acquire the right example of tracks. Regularly with a slight layer of photograph oppose, the copper on the uncovered printed circuit sheets is covered. Through a photograph cover or visual film enumerating the tracks required, it is then presented to light. Onto the photograph oppose, the picture of the tracks is passed along these lines. In a designer, so just those region of the board where tracks are required are canvassed in the oppose, the photograph oppose is put with this total.

It is set into the engraving foam required measure of time, knowing the thickness of the copper on the load up and the grouping of the ferric chloride. Some definition is lost as the ferric chloride will generally undermine the photograph oppose In the event that the printed circuit sheets are put in the engraving for a really long time.

Different strategies are additionally accessible albeit most PCB sheets are fabricating utilizing visual handling. Utilizing a particular profoundly exact processing machine is one. To process away the copper in those areas, the machine is then controlled where the copper isn't needed. From documents created by the PCB plan programming, the control is clearly determined and robotized.

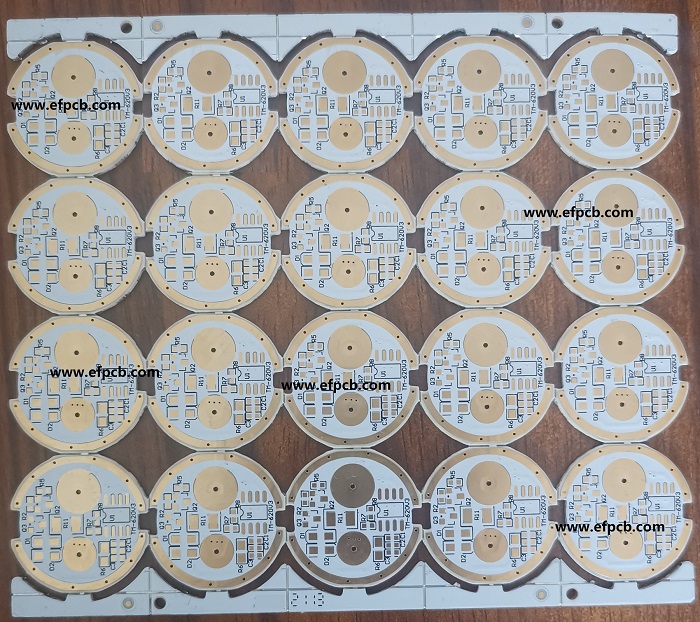

Multi-facet PCB

Giving all the network that is required utilizing simply the different sides of the PCB isn't generally imaginable with the intricacy of electronic circuits expanding. At the point when other comparable sheets and thick chip are being planned, this happens regularly. Multi-facet sheets are required when this is the situation.

Despite the fact that it requires an impressively more noteworthy level of assembling process control and exactness as well as uses similar cycles concerning single layer sheets, the production of multi-facet printed circuit sheets. The PCB Creation should be effective.

These are then reinforced together to create the by and large PCB and the sheets are made by utilizing a lot more slender individual sheets, one for each layer. To forestall the completed PCB from turning out to be too thick, the singular sheets should become more slender as the quantity of layers increments. Furthermore to guarantee that any openings line up, the enlistment between the layers should be exceptionally precise.

The board is warmed to fix the holding material to bond the various layers together. A few issues of twist are come about because of this. an unmistakable twist on them is available in enormous multi-facet sheets in the event that they are not planned accurately.

RF PCB vias and openings

To interface the different layers together at various places, Openings or vias or by means of openings are required frequently inside a PCB. To empower leaded parts to be mounted on the PCB, Openings may likewise be required. Moreover, you might require some fixing openings.

Ordinarily copper layer is available in the inward surfaces of the openings so the layers of the board are associated electrically. Utilizing a plating cycle, these plated through openings are created. The layers of the board can be associated along these lines.

Utilizing the information being provided from the PCB computer aided design plan programming and mathematically controlled boring machines, Penetrating is then achieved. It is significant that the expense of the PCB make is decreased by diminishing the quantity of various sizes of openings.

In the applicable layers earlier, these visually impaired vias are bored to the PCB layers being fortified together.

RF PCB binds oppose and fastens plating

To keep the not to be bound regions safeguarded by a layer of weld oppose, it is important during the fastening of a PCB. Undesirable shortcircuits on the PCB sheets brought about by the weld are forestalled by the expansion of this layer. a polymer layer is typically present in the bind oppose and from patch and different toxins, it safeguards the board. The weld oppose variety is typically red green or profound.

Either SMT or leaded to bind to the board effectively, uncovered region of the board are typically plated with weld or tinned to empower the parts added to the board. Every so often some board segment or the total board might be gold plated. Assuming that some copper fingers are to be utilized for edge associations, this might be relevant. A decent association is presented for a minimal price by the gold as it offers great conductivity and won't discolor.

RF PCB Silk Screen

Printing text and setting other little printed idents onto a PCB is vital frequently. In stamping part areas and recognizing the board, it helps with shortcoming finding, and so on. To add the markings to the board, a silk screen produced by the PCB plan programming is utilized. For the uncovered board have been finished, it is utilized after the other assembling processes.

RF PCB model

Making a model prior to resolving to full creation is fitting as a piece of any improvement cycle regularly. In printed circuit sheets where a PCB model is made regularly and tried before full creation, the equivalent is valid. Regularly as there is consistently strain to finish the equipment configuration period of the item improvement a PCB model should be made rapidly. A fundamental component of the gadgets creation lifecycle is The PCB fabricating process. Numerous new areas of innovation is utilized by RF PCB producing and to be made both in the decrease of tracks utilized and sizes of parts as well as in the sheets dependability, this has empowered critical upgrades.