Know About Using Various Gold Types in Soft Gold PCB

Keywords: Soft Gold PCB

Picking the most helpful gold PCB like Soft Gold PCB surface completion can be fairly to a greater extent a secret while gold plating is utilized for printed circuits sheets (PCBs) oftentimes. To match your circuit board needs, figuring out functional purposes of gold completes like gold fingers, ENEPIG, and ENIG and the various creations can assist you with tracking down the right completion.

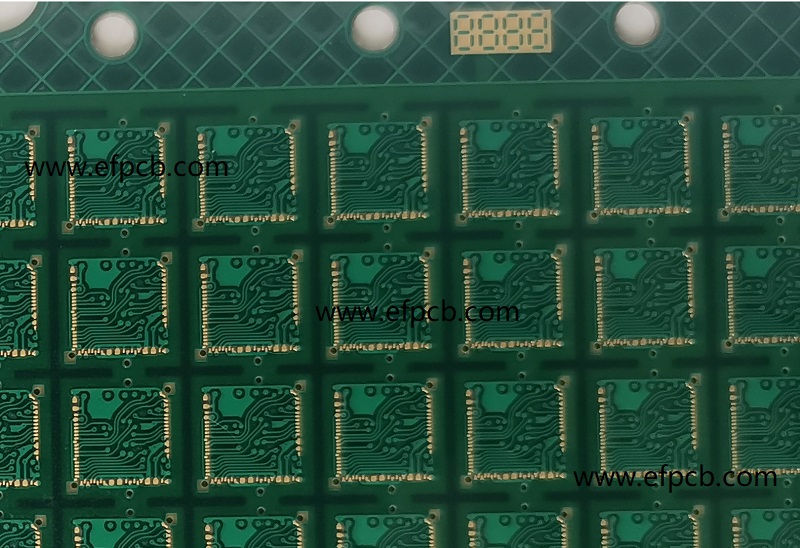

PCB Assembling Including Gold Utilized

The virtue is 99.9% unadulterated gold making this surface completion for all gold applications about PCBs. Applied to printed circuit sheets, there are a ton of sorts of gold completes some remain part of the completed gathering. To safeguard the hidden electro less nickel plating and finish for the gathering system, through-openings and SMT devises are utilized.

PCB Gold Surface Completions Types

Gold Fingers

In different applications, Gold fingers are helpful. For the association of the edge card, a few gold contacts are great. A gold-plated connector of a PCB is a gold finger. A gold plated terminal is highlighted by Gold fingers. The smooth exchange of force and information in a PCB is permitted by this surface completion. For edge contacts, Gold fingers are utilized uncommonly. Protection from wearing and tearing is worked with by these.

Submersion Gold/Electro less Nickel (ENIG)

To the copper surface, nickel and gold are connected to this surface wrapping up. For this interaction, complex power supply gadgets are not utilized. ENIG process frequently goes through nickel plating, pickling, initiation, miniature drawing, cleaning, and electro less. Plating of auto-reactant nickel on the copper cushion is the significant stage here. Boundaries like ph, temperature, and added substance fixation are utilized.

A deterrent to the copper is presented by the nickel. It assumes the part of surface on the parts are bound by the PCB producers. The nickel is safeguarded by the gold safeguards and low contact opposition is presented too. ENIG in the PCB business is the most usually used finish in Delicate Gold PCB.

Electroplated Nickel Gold (ENG)

Since the development of PCB, Electroplated Nickel/Gold have been existing. With a nickel layer, the surface guide of the circuit board is covered with this sort of surface completion. To cover the surface, it then, at that point, utilizes a layer of gold. Gold is set in the substance syrup after the nickel fluid has been discarded independently. In the electroplating chamber, the maker then, at that point, drenches the pre-handled PCB. In the electronic business, This PCB gold plating is famous. This is on the grounds that gold is wear and oxidation - safe as a material.

The Drenching Gold and Gold Plating Distinction

Drenching gold and Gold plating processes on a PCB are two different techniques. Synthetic testimony is the submersion gold interaction on a PCB. Applying a slight layer of gold is engaged with the submersion gold cycle. In gold wire and aluminum holding, Drenching gold is found. Anyway to take electrolytic gold plating, its restricted thickness and attachment make it improper.

Storing gold on the outer layer of a metal is engaged with Gold plating. The standards of electroplating are taken on in this plating. A nickel-gold covering is saved on the outer layer of the PCB in the submersion gold cycle. While drenching gold is delicate gold, Gold plated sheets are hard gold. This shows gold plated sheets are impervious to wearing. The drenching gold sheets are not impervious to wearing.

When contrasted with a gold plating board, the gold in submersion gold is thicker. Binding submersion gold is simple. Less bind issues accompany it. Directing pressure is a lot simpler for drenching gold. This is on the grounds that when contrasted with gold plating, it is milder. The variety is one more contrast between submersion gold and hard gold plating. When contrasted with hard gold plating, Submersion gold is more yellow.

Nickel and gold on its cushion are highlighted by submersion gold board. Consequently, the sign on the copper layer will not get impacted by the sign transmission in the skin. When contrasted with the submersion gold cycle, the gold plating process is more affordable. Unadulterated gold is utilized to make drenching gold. Different components are joined in Gold plating to change the grain construction of the gold.

Gold Plated Circuit Board Properties

In the hardware business, the gold plated circuit board is utilized regularly. Gold is an important asset to individuals because of the stylish appearance. Anyway in the gadgets business, its properties make it an exceptionally valued material. Extraordinary mechanical, electrical, and warm properties are highlighted by Gold. For being utilized in electronic parts, these pursue them an ideal decision. A great deal of properties are included by a gold plated circuit board. The properties include:

Extended area of association

A circuit board that is gold plated is exceptionally bendable and flexible. As a material, Gold under tension can loosen up into flimsy wire. Along these lines, more surface region is covered by it. Electronic gadgets are empowered to continue to work well by the gold plated circuit board adaptability.

Heat Security

For applications including high temperatures, a gold plated circuit board is great. Different materials are shielded from overheating by this circuit board. A dissolving point of 1062 ℃ is included by Gold. The ability to direct intensity is displayed by gold. Under extraordinary temperatures, Gold plated circuit sheets will perform well. For applications presented to high temperatures, this makes it ideal.

Wearing Opposition

Gold plated circuit sheets offer greater strength. Wearing and tearing is opposed by This PCB. The circuit board has a covering filling in as a safeguard for the electronic parts. To worrying corruption, Gold plated sheets aren't helpless. It won't harm because of worrying as gold doesn't consume. The gold plating on this board endures long.

Reflectivity

Gold is an ideal decision in parts because of the intelligent idea of gold. More noteworthy measures of UV radiation are included by Gold plated circuit sheets. Keeping gadgets in cool circumstances, they reflect infrared radiation. For shuttle and satellite plan, gold plated circuit sheets are center materials because of this.

Protection from Erosion

Gold plated circuit sheets display this as extraordinary properties. Gold is impervious to erosion. This implies that any erosion can be endured by it. Any rust or substance won't influence it. It won't harm albeit gold can discolor. For electronic parts, obstruction of gold to consumption is significant. This is on the grounds that less practical electrical association might be come about because of oxidation.

End

You want to pose specific inquiries with respect to specific applications to your provider. Examining prerequisites for Delicate Gold PCB from the get-go in the phases of configuration is likewise proposed. This guarantees deciding the best cycles and building the most elevated unwavering quality.