Know about the Process Performed before PCB Assembly

Keywords: PCB Assembly, PCB Assembly China

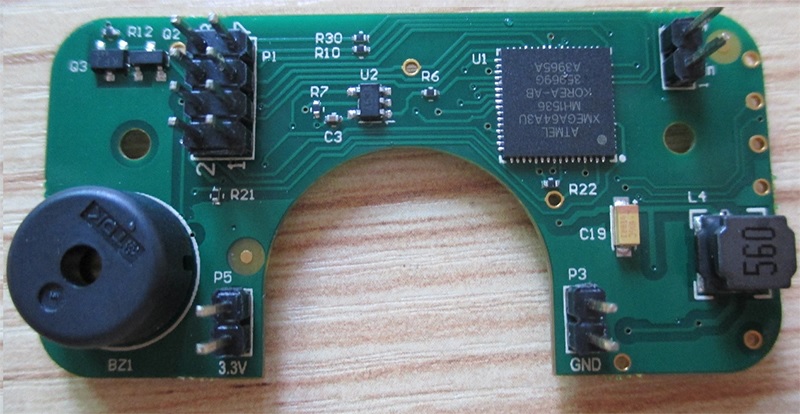

In electronic devices, CBs or Printed Circuit Boards are an integral part. They are generally the backbone that enables the components to communicate with each other. If you reach for your nearest electronic device and you will find that chances are that it contains a PCB. In this article, we will be discussing the events that happen before the PCB assembly begins.

Design Process of PCB

The PCB design process is where the first conceptualization of PCB is done. For the contacts engineers create a blueprint on how the PCB should be layered. Various factors like the dimensions of the components, their orientation, the type of PCB, and even the soldering process are taken into account by the design process. In designing PCB there are different tools that can be used.

DFM/DFA Check

Unless the core design passes a check for quality and consistency a PCB Assembly China does not get approved for assembly. DFM /DFA is the process of checking PCBs designs for flaws or imperfections before they go into the actual fabrication.

The PCB is inspected to see if it has any defects in this process. To the product, in the long run, even minor imperfections can cause damage.

PCB Fabrication

PCB fabrication is the process that builds the actual base from the design. For the raw materials that make up the board, a PCB has specific requirements. The components of a PCB are:

Solder mask: Also referred to as the Skin of the PCB. It is a layer that on top of the PCB is applied to protect the copper from the environment. Problems like short circuits or oxidation can occur due to exposure to atmospheric moisture. In PCB the signature green color is actually the color of the solder mask.

Copper: In PCB Copper is used in two forms copper coating and copper foil. In a PCB Copper is the material that carries electric current. It connects various components together. In PCB terminology, copper lines that we observe on the PBC are called copper traces.

Silkscreen: For PCBs silkscreen is the ink. It even denotes important information about the PCB.

Dielectric material: This is a non-conducting material that actually makes up the base or the core of the PBC. It is made from fiberglass. The main benefit of using fiberglass is that it is both an insulator and provides sufficient strength to the PCB Assembly.