Know About the Key Properties of Ceramic PCB

Keywords: Ceramic PCB

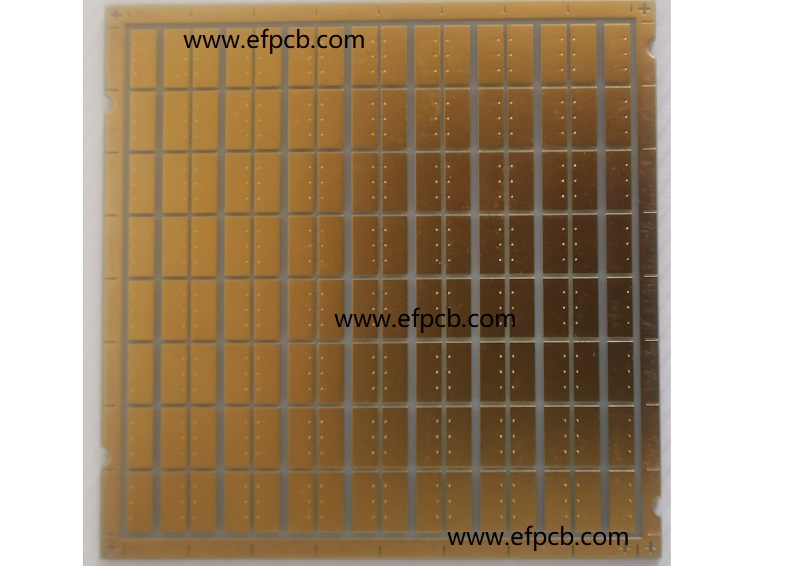

Ceramic PCB, also known as ceramic substrates or alumina PCBs, are a specialized type of printed circuit board that employs ceramic materials as the base substrate. Unlike conventional PCBs that use epoxy-based materials, ceramic PCBs utilize ceramics like alumina (aluminum oxide) or aluminum nitride. The choice of ceramic material depends on the specific requirements of the application.

Key Properties of Ceramic PCBs

High Thermal Conductivity: One of the standout features of ceramic PCBs is their exceptional thermal conductivity. This property allows these boards to efficiently dissipate heat generated during electronic operations. As electronic devices become more powerful and compact, effective heat dissipation is crucial to prevent overheating and ensure optimal performance.

Mechanical Strength: Ceramics are inherently robust and provide high mechanical strength. This makes ceramic PCBs resistant to physical stress, ensuring durability and reliability in demanding environments. The enhanced mechanical properties make them suitable for applications where traditional PCBs may fail to meet the requirements.

Low Dielectric Loss: Ceramic materials exhibit low dielectric loss, meaning they have excellent insulation properties. This characteristic is particularly advantageous for high-frequency application where signal integrity is paramount. Ceramic PCB excels in maintaining signal quality and reducing the risk of signal distortion.

Applications of Ceramic PCBs:

Power Electronics: The high thermal conductivity of ceramic PCBs makes them ideal for power electronics applications. Devices such as power modules, inverters, and converters benefit from the efficient heat dissipation offered by ceramic substrates, improving overall performance and reliability.

LED Lighting: The LED industry has embraced ceramic PCBs for their ability to withstand high temperatures and provide effective thermal management. Ceramic substrates enhance the longevity and efficiency of LED lights, making them a preferred choice for lighting applications.

Aerospace and Automotive Electronics: The aerospace and automotive industries demand electronic components that can withstand extreme conditions. Ceramic PCBs, with their robustness and thermal performance, find applications in critical systems like engine control units (ECUs) and avionics.

RF and Microwave Devices: The low dielectric loss of ceramic materials makes them well-suited for radio frequency (RF) and microwave applications. Ceramic PCB plays a crucial role in the development of antennas, radar systems, and communication devices where signal integrity is of utmost importance.