Know About the IC Substrate Classifications

Keywords: IC Substrates, IC Substrates China

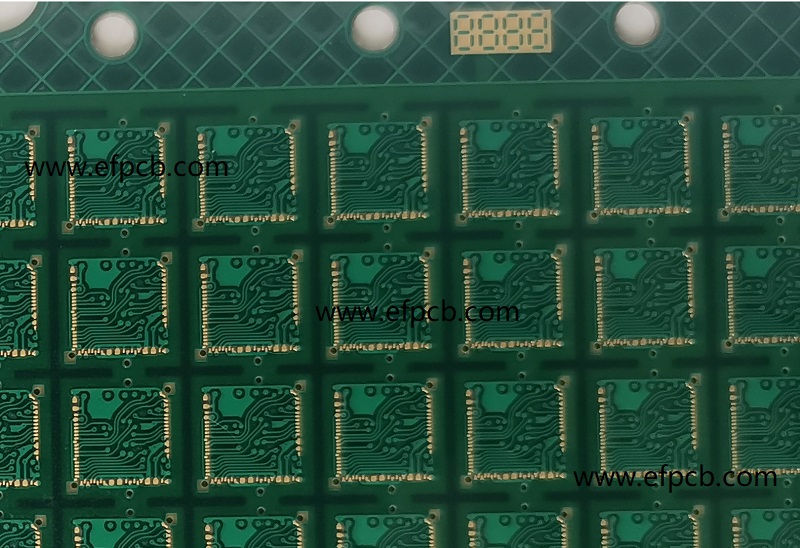

Along with any layer HDI PCB and flex-rigid PCB, which are now extensively used in telecommunications and electronics upgrades, IC Substrates PCB has experienced an explosion in popularity and applications as one of the most sophisticated PCB (Printed Circuit Board) types.

IC Substrate

A specific kind of baseboard called an IC substrate is used to package bare IC (integrate circuit) chips. The IC, which connects the chip and circuit board, is a middle product having the following features:

It can protect, fortify, and support IC chips by creating a thermal dissipation tunnel. It can also capture semiconductor IC chips. There is routing within to link the chip and PCB.

Categories of IC Substrate

According to packaging types

- IC Substrate for BGA. This type of IC substrate has good electrical and thermal performance and may significantly expand chip pins. As a result, it is appropriate for IC packages with pin counts of more than 300.

- IC Substrate for CSP. A single-chip package known as a CSP is lightweight, compact, and has an IC-like size. The principal applications for CSP IC substrates are electronic items with few pins, communications equipment, and memory products.

- Substrate for FC IC. A sort of packaging by flipping a chip called an FC (Flip Chip) has low signal interference, low circuit loss, good performance, and efficient heat dissipation.

- IC Substrate for MCM. The acronym MCM stands for multi-chip module. One package may include many chips with various functions thanks to this kind of IC Substrates China. As a result, the product's qualities, such as its lightness, thinness, shortness, and miniaturization, might make it an ideal answer. Naturally, this sort of substrate doesn't perform as well in signal interference, heat dissipation, precise routing, etc. as numerous chips are bundled into one package.

According to a material attribute

- Stiff IC Substrate Epoxy resin, BT resin, or ABF resin are generally used in its production. It has a CTE of 13 to 17 ppm/°C (coefficient of thermal expansion).

- Flexible IC Substrate Its main ingredients are PI or PE resin, and its CTE ranges from 13 to 27 ppm/°C.

- Ceramic Substrate for ICs. Ceramic materials like silicon carbide, aluminum nitride, or aluminum oxide are typically used to make it. It has a CTE of around 6 to 8 ppm/°C, which is considered to be rather low.

IC Substrates Grouped according to the bonding method

- Bonding of wire

- FC Bonding

- TAB (Tape Automated Bonding)