Know About the High-Density Interconnect (HDI) Flexible PCBs

Keywords: Flexible PCB Manufacturer

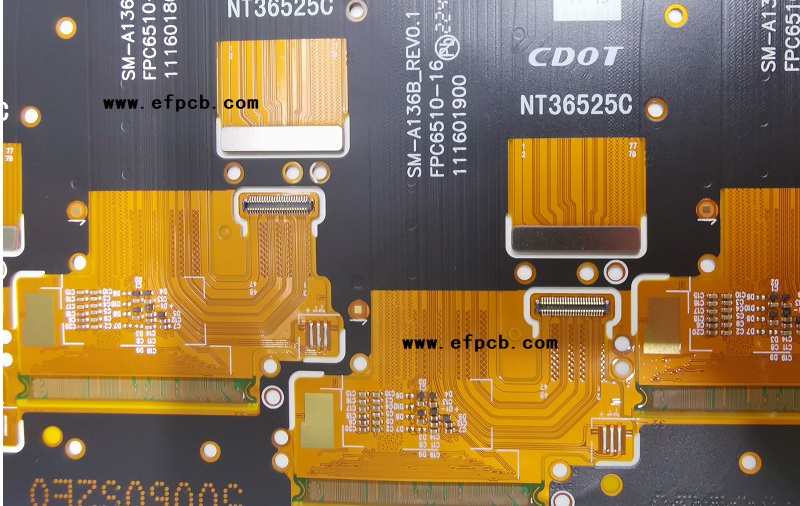

Flexible PCBs, or flex circuits from Flexible PCB Manufacturer, have been in use for several years, offering the advantage of being bendable, lightweight, and adaptable to various form factors. HDI, on the other hand, refers to High-Density Interconnect, a technology that allows for the integration of intricate circuitry within a smaller footprint. When these two technologies come together, the result is a powerful combination that redefines the capabilities of electronic devices.

Key Features of HDI Flexible PCBs

Miniaturization

HDI Flexible PCBs enable the creation of highly compact circuits with a significantly reduced footprint. This is achieved through advanced manufacturing techniques such as microvias, which allow for the creation of smaller holes and finer traces.

Increased Component Density

The use of microvias and advanced layer stacking techniques in HDI Flexible PCBs facilitates a higher density of components. This means that more electronic components can be integrated into a smaller space, leading to more functionality in a given device.

Enhanced Signal Integrity

With reduced signal path lengths and minimized interference, HDI Flexible PCBs contribute to improved signal integrity. This is crucial for applications where high-speed data transmission and reliable signal quality are paramount, such as in smartphones, wearables, and communication devices.

Flexibility and Durability

As the name suggests, flexible PCBs from Flexible PCB Manufacturer offer the advantage of bending and conforming to various shapes. This flexibility, combined with the durability of HDI technology, makes these PCBs ideal for applications where mechanical stress and repeated bending are common, such as in medical devices and automotive electronics.

Applications of HDI Flexible PCBs

Consumer Electronics

HDI Flexible PCBs have found widespread use in consumer electronics, contributing to the slim and lightweight designs of smartphones, tablets, and laptops. The flexibility allows for innovative form factors, and the miniaturization enables the integration of powerful features in compact devices.

Medical Devices

In the medical field, HDI Flexible PCBs are employed in devices such as wearable health monitors and medical imaging equipment. Their flexibility and compact design make them well-suited for applications where space is limited, and reliability is critical.

Automotive Electronics

The automotive industry benefits from the use of HDI Flexible PCBs from Flexible PCB Manufacturer in various electronic components, including infotainment systems, advanced driver-assistance systems (ADAS), and sensors. The compact nature of these circuits contributes to the efficient use of space in modern vehicles.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5IC Substrate | Comprehensive Guide (2021)

- 6Top HDI PCB Manufacturers (2024)

- 7How to Make mSAP PCB?

- 8The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 9Top 10 IC Substrate Fabricators (2024)

- 10Top 10 Flexible PCB Factories in 2025

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact