Know About the Benefits and Process of Through-Hole Assembly Technique

Keywords: PCBA Assembly China

In the realm of electronics manufacturing, the through-hole assembly process stands as a time-tested method for crafting durable and reliable circuitry. Through-hole PCBA Assembly China continues to hold its ground in applications demanding robust connections, high-power components, and superior mechanical stability.

The Advantages of Through-Hole Assembly

- Mechanical Stability: Components are secured by passing leads through drilled holes in the PCB, creating a robust connection that is less prone to mechanical stress, vibrations, and thermal cycling.

- High-Power Applications: High-power components generating considerable heat during operation can be efficiently mounted on the PCB, with the leads acting as heat sinks that dissipate excess heat.

- Reliability: Through-hole components offer greater reliability, especially in environments with extreme temperatures, vibrations, or high levels of humidity. This makes them ideal for applications in the aerospace, automotive, industrial, and military sectors.

- Manual Assembly and Repair: Through-hole PCBA Assembly China is more forgiving during manual assembly and repair processes. Components can be inserted and soldered manually, allowing for easier troubleshooting and repair if a defect is detected.

The Through-Hole Assembly Process

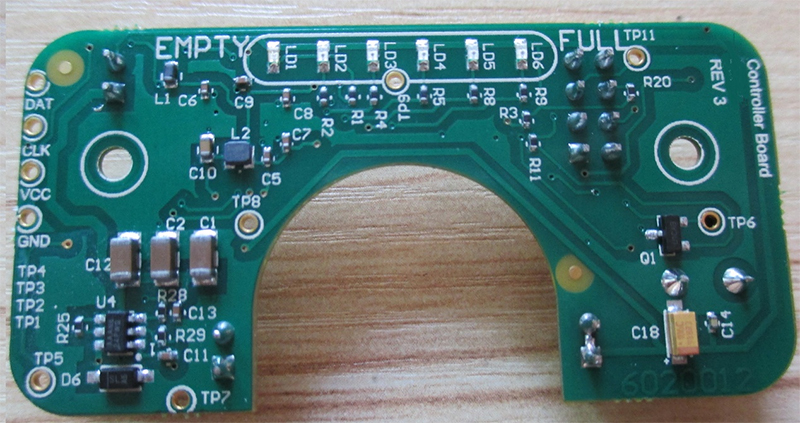

- Component Placement: Components such as resistors, capacitors, diodes, and connectors have leads that are inserted through holes in the board.

- Insertion: The leads are manually or automatically inserted through the holes on the PCB. For automated assembly, machines known as insertion equipment are used to precisely position the components.

- Bending and Trimming: Once the components are inserted, the excess lead length is trimmed to an appropriate length. The leads are then bent to ensure they stay in position during soldering.

- Soldering: Soldering is a crucial step that involves applying heat to melt the solder and create a solid electrical and mechanical connection between the component leads and the PCB. Solder can be applied using wave soldering or hand soldering techniques.

- Inspection: After soldering, a thorough inspection is performed to identify any defects or soldering issues. This step ensures the quality and reliability of the assembly.

- Cleaning: Flux residues from the soldering process need to be cleaned from the PCB to prevent corrosion and other issues. Cleaning is particularly important in through-hole assembly due to the potential for trapped flux residues.

- Testing: The assembled PCBA Assembly China undergoes functional testing to ensure all components are functioning as intended and the connections are solid.